Aluminum Die Casting Manufacturer in China | Yongzhu Casting

Precision from Design to Delivery An IATF-Certified Leader in Custom Die Casting & CNC Services

Since 2004, Serving Automotive, Medical, Energy, Lighting, and Industrial Sectors Worldwide. [ Fast lead time | MOQ as low as 100pcs | Over 20 Years of Experience]

Our Core Capabilities at a Glance

ISO 9001 & In-House Quality Control

We follow strict inspection standards, including 100% visual and dimensional checks.

Up to 2000T Die Casting Machines

From 160T to 2000T, covering parts from 50g to 50kg with high consistency and repeatability.

20+ Years in Aluminum Die Casting

Since 2004, Yongzhu specializes in aluminum die casting for industrial and automotive sectors.

CMM Inspections Capability

Coordinate Measuring Machines up to 1000×800mm to ensure critical tolerance requirements are met.

How We Build Quality Aluminum Die Castings

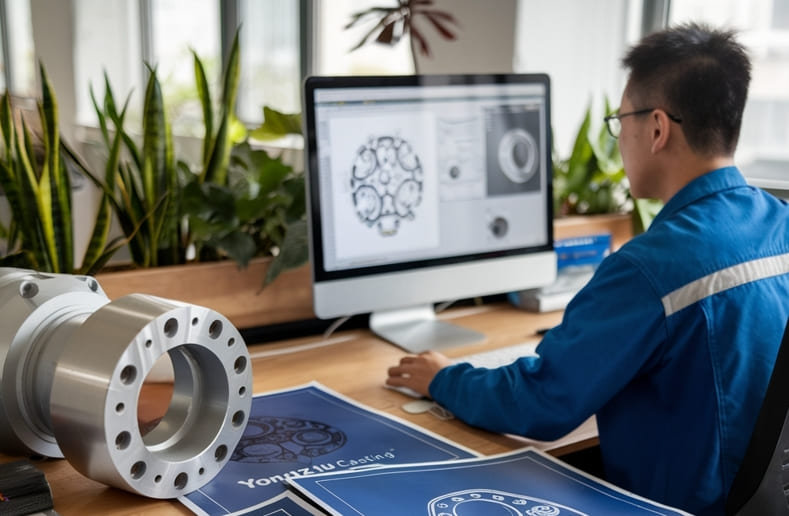

Located in Zhejiang, Yongzhu Casting operates a 5,000㎡ die casting factory.

We provide complete aluminum part manufacturing using a wide range of casting and fabrication methods:

• Die Casting

• Sand Casting

• Gravity Casting

• Precision Casting

• Extrusion

• Stamping

• Welding

These processes allow us to select the most cost-effective and technically appropriate solution for each project, whether it’s for complex structural parts or simple housings.

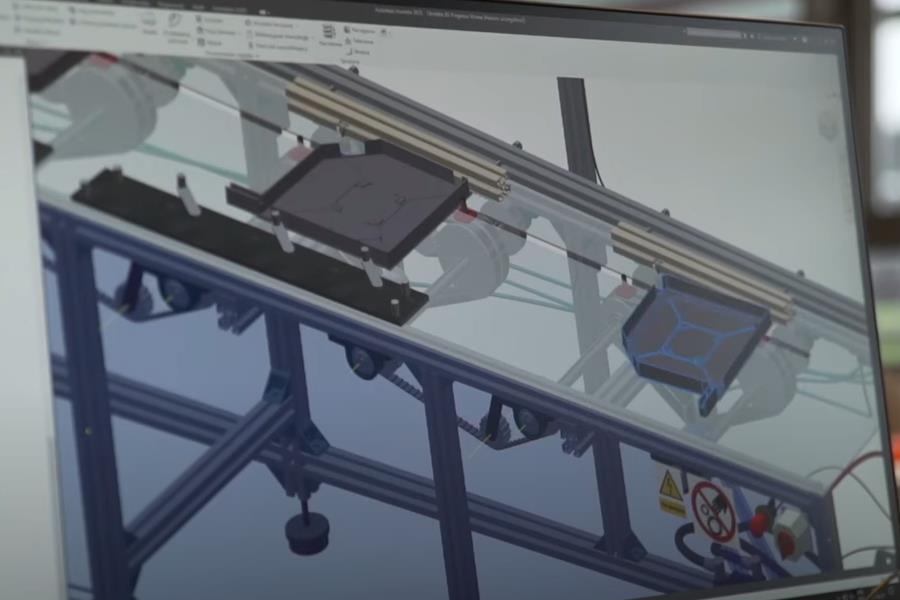

From the initial mold design to final product inspection, every casting follows a standardized workflow:

Design & DFM support

Melting & casting (HPDC)

Trimming & deburring

Surface finishing (e.g., powder coating, shot blasting)

100% dimensional and visual inspectionThis ensures part-to-part consistency, compliance with tolerances, and optimized surface finish for your applications.

We serve OEMs and system integrators across various industries, including:

Automotive: Controller housings, gearbox covers

Energy: Inverter and charger casings

Medical: Diagnostic device frames, enclosures

All components are custom-made to your drawings and delivered with full traceability.

Our Die Casting, Machining & Surface Finishing Services

At Yongzhu Casting, we provide full-process aluminum die casting services—from mold design to surface-finished, CNC-machined components. With everything handled in-house, we reduce lead times, optimize cost, and ensure strict control over every step of your project.

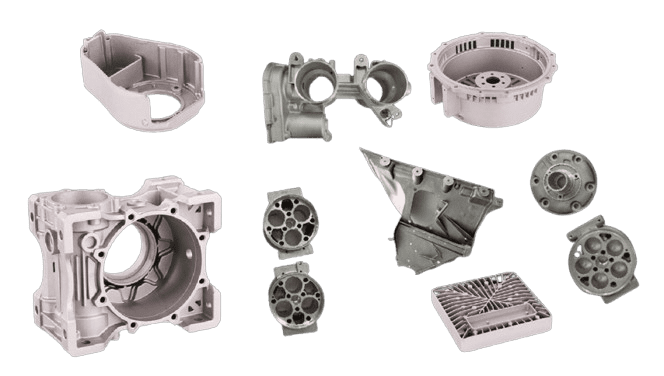

High Pressure Die Casting

We use aluminum alloy casting machines ranging from 160T to 2000T to produce parts from 50g up to 50kg. Our process ensures consistent dimensions, fast cycle times, and low porosity. Ideal for housing, brackets, and structural parts.

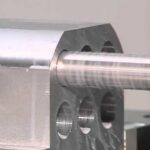

CNC Machining

All die-cast parts can be post-processed with precision CNC milling, drilling, tapping, and reaming. We support tolerance as tight as ±0.05mm, with machining centers dedicated to both prototypes and mass production.

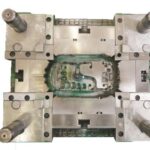

Mold Design & Fabrication

Our in-house tooling department designs and builds custom molds, supporting multi-cavity and long-life steel tools. We offer DFM feedback and mold maintenance to ensure stable production and repeatability.

Surface Treatment

We offer a variety of surface finishes such as sandblasting, powder coating, anodizing, shot peening, and painting. These treatments enhance corrosion resistance and product appearance based on your application needs.

Quality Control & Testing

All parts undergo dimensional and visual inspection. For critical parts, we support CMM measurement, salt spray testing, tensile tests, and pressure leak tests per request. QC reports are provided with each batch.

Custom OEM Projects

We support low-MOQ and fully customized die casting projects based on your 2D/3D drawings. Industries served include automotive, energy, medical, lighting, and machinery.

Your Project, Our Commitment to Precision

Aluminum Die Casting Parts Built to Your Drawings & Deadlines

We understand how critical your project timelines and quality standards are. At Yongzhu Casting, we manufacture aluminum die-cast components exactly to your 2D/3D drawings, with in-house mold making, machining, and surface finishing.

Whether you’re building a prototype or mass production batch, our engineers work closely with you to deliver precision parts—on time and within budget.

From single samples to high-volume orders, we support custom OEM and ODM projects for industries like automotive, energy, lighting, medical, and machinery.

Custom Aluminum Die Cast Parts for Global Clients

You’re not just looking for a supplier—you’re looking for a partner who understands deadlines, tolerances, and trust.

We believe growth is mutual. We grow when our customers grow. That’s why at Yongzhu Casting, we keep refining our process, so your products perform better in the market.

What Global Buyers Say About Yongzhu Casting

Whether you’re a mechanical engineer, a sourcing specialist, or a project manager, our customers value what we deliver: consistent quality, responsive service, and reliable aluminum die casting solutions.

Our VTOL cargo drone switched from a machined 720 g billet shell to a 530 g die‑cast housing from Yongzhu Casting. Rotor hub temps dropped 9 °C and flight endurance rose 7 minutes on a 60 min mission—critical for last‑mile deliveries.

Marine radar pedestals on our coastal patrol vessels needed MIL‑DTL‑15024 compliance. The ADC12 die‑cast base with Yongzhu’s 120 µm powder coat survived 2 500 h ASTM B117 and retained torque at 600 N·m—no repaint between dry‑docks.

Casting the collaborative‑robot shoulder as a single 2.9 kg piece eliminated eight bolts and raised fatigue life from 3 million to 4.1 million cycles. Payload grew 0.4 kg without motor upgrade—a direct yield increase for our users.

Polymer housings distorted under hot pesticide. Yongzhu’s vacuum die‑cast aluminum body (1.6 kg) passed a 20 bar burst test and cut field leaks from 3.5 % to < 0.2 % across 45 000 units.

An extruded heat sink couldn’t shed 350 W in a fan‑less base‑station radio. The new topology‑optimised die‑cast sink from Yongzhu trims 15 °C off hotspot temperature, allowing full‑rate transmit in 45 °C desert sites.”

Our steel shell dented during 100 G SAE J1455 drop. The die‑cast aluminum enclosure from Yongzhu absorbed the shock with zero deformation and lowered harness weight by 0.8 kg, improving operator feedback vibrations by 18 %.

Our Core Industries

Yongzhu can fabricate any aluminum die cast parts for your applications, just send us your drawing and get our best quote.

Automotive

Yongzhu can produce automotive parts such as engine parts, transmission components through our die casting.

Energy

We can provide aluminum parts for use in the energy industry (e.g. Gearbox Housing, Cable Trays, etc.).

Light

Our light fabrication services can produce aluminum LED HeatSinks, LampHousings, Reflectors, Bracketry.

Medical

We can produce imaging equipment casings, surgical instrument handles, and ventilator housing.

Home Furnishings

Our home appliance parts such as lighting fixtures, furniture frames, and decorative hardware using aluminum die casting.

Machinery and Equipment

We provide industrial machinery components such as pump housings, motor enclosures, and gearboxes.

Why choose YONGZHU

20+ years of manufacturing experience

Zhejiang Yongzhu Casting Technology Co., Ltd., formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

Over these two decades, we have accumulated a wealth of industry knowledge and experience, all of which has helped us and our customers move forward.

Competitive Pricing & Servics

From mold manufacturing, casting processing to surface treatment, we independently complete one-stop service. This enables us to provide quality die casting products at competitive prices.

Customized Solutions

We can fulfill customers’ customized products and OEM,ODM requirements, which are all routine processes. Whether it is the technical team or the sales team, real-time tracking of orders.

We uphold that quality is service. Making customers trouble-free is the best service.

Fast shipment

We have casting equipment of different tonnages, the largest being 2000 tons. Can able to ensure rapid delivery of orders. You can rely on our fast supply to implement your plans.

Real Factory

The company is ISO 9001, SGS and TS16949 certified and manufactures high quality aluminum die castings for international customers.

iron casting Vedio

Service Process

Better communication Better service

Project Initialization

Reviewing your aluminum die casting specifications for clarity.

Precision Production

Crafting each component to your exact die casting needs.

Rigorous Inspection

Ensuring every die casting piece meets global standards.

Timely Dispatch

Prompt dispatch of your aluminum die casting orders.

Process

FAQ

What aluminum grades do you use for die casting?

We commonly use ADC12, A360, A380, and custom aluminum alloys depending on strength, thermal, and fluidity requirements. Material certificates are available upon request.

What is your minimum order quantity (MOQ)?

We support low-MOQ projects. The minimum order can start from 100 pieces, depending on part complexity and size.

Can you produce based on my 2D or 3D drawing?

Yes. We manufacture 100% based on client drawings (PDF, STEP, IGS). If needed, we provide DFM feedback before tooling starts.

What’s your typical lead time for tooling and production?

Tooling takes 20–30 working days, while production lead time is 15–25 days depending on order quantity and finishing process.

What industries do you serve with aluminum die casting?

We supply parts to automotive, medical, lighting, energy, robotics, telecom, and machinery industries worldwide.

Do you provide quality inspection and reports?

Yes. All parts go through 100% visual and dimensional inspection, with optional CMM, X-ray, salt spray, and tensile testing. Reports are provided with each shipment.

Can you support surface finishing services?

Yes, we offer sandblasting, powder coating, anodizing, painting, and custom finishes according to project needs.

How do you ensure drawing confidentiality?

We sign NDAs on request and restrict access to sensitive files internally. All design files are managed securely during project execution.

Do you provide sample or prototype parts?

Yes. We can provide samples after first tooling trial (T1) and make necessary modifications before mass production.

Can you export globally and handle customs documents?

Yes, we export to over 30 countries and provide CO, Form A, packing list, commercial invoice, HS codes, and more.

BLOG

Request A Free Quote

We look forward to hearing from you!

Whether you need a quote or have a die casting question, send us a message. Our experts will respond within 24 hours to assist you.