Hi, I’m Lai Haijiang, owner of Yongzhu Die Casting since 2004. Passionate about aluminum die-casting? Let’s chat! We craft custom aluminum parts for various industries and offer both manufacturing and wholesale services. Interested in being our overseas agent? Drop me an email with your ideas, and I’ll get back to you swiftly!

How is Aluminium Used in Automotive Die Casting?

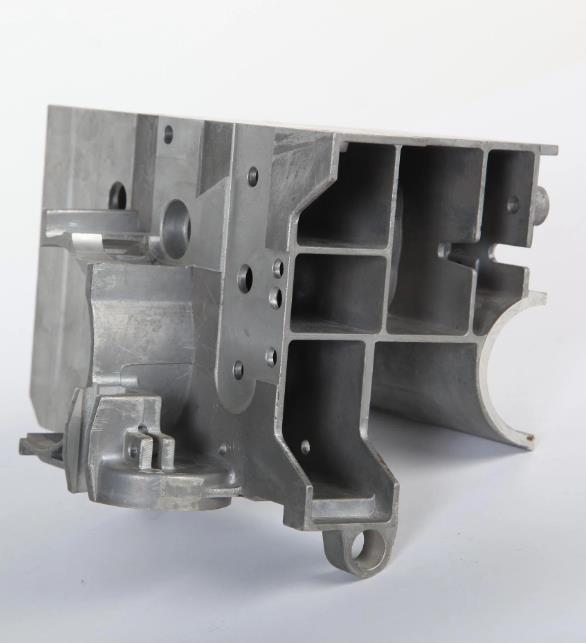

Aluminium’s application in automotive die casting is multifaceted, offering lightweight, durable components essential for modern vehicle manufacturing. The process involves injecting molten aluminum into molds to produce parts with complex shapes and high precision.

Key elements of automotive manufacturing, such as engine components, transmission parts, and structural elements, often rely on aluminum die casting. This method is particularly suited for producing large volumes of parts with consistent quality.

What are the Most Common Alloys for Aluminium Die Casting?

The most prevalent aluminum alloys used in die casting include A380, A383, and A360. Each alloy offers unique properties: A380 for its excellent fluidity and mechanical properties, A383 for better die filling, and A360 for higher corrosion resistance and strength.

- A380 alloy is a staple in the automotive industry due to its balanced combination of strength, durability, and cost-effectiveness.

- A383 alloy, often chosen for intricate die castings, offers ease in filling the die, crucial for complex shapes.

- A360 alloy stands out for its superior strength and corrosion resistance, making it suitable for more demanding applications.

Why Choose Aluminium for Die Casting in Automotive Parts?

Aluminium’s lightweight nature significantly contributes to fuel efficiency and emission reduction in vehicles. Its strength-to-weight ratio is a key factor in choosing it for automotive parts.

The recyclability of aluminium aligns with environmental sustainability goals, making it an increasingly popular choice in the automotive industry.

What Sets Apart Aluminium Die Casting in Automotive Applications?

Aluminium die casting in automotive applications is distinguished by its ability to produce complex parts with high precision and excellent surface finish. This process allows for the integration of multiple functions into a single component, reducing assembly costs and increasing efficiency.

- Precision: Aluminium die casting achieves high dimensional accuracy, essential for automotive parts.

- Efficiency: The process enables the production of large quantities of parts with consistent quality.

- Cost-effectiveness: Aluminium’s abundant supply and recyclability contribute to its economic advantages in die casting.

How Do Aluminium Die Casting Auto Parts Compare to Other Materials?

Aluminium die cast parts offer a superior balance of strength, weight, and durability compared to other materials like steel or plastic. While steel is stronger, it’s also heavier, which can impact vehicle efficiency.

- Weight Advantage: Aluminium is lighter than steel, enhancing fuel efficiency.

- Durability: Resistant to corrosion, aluminium parts have a longer lifespan.

- Cost-Efficiency: Although initially more expensive than plastic, aluminium’s durability and strength offer long-term savings.

What Are the Key Properties of Aluminium Die Casting Alloys?

Aluminium die casting alloys are known for their high strength-to-weight ratio, excellent thermal conductivity, and good corrosion resistance. These properties make them ideal for various automotive applications.

- Thermal Conductivity: Essential for heat dissipation in engine parts.

- Corrosion Resistance: Increases the longevity of automotive components.

- Lightweight: Contributes to overall vehicle efficiency and performance.

Why is Aluminium a Preferred Material in Die Casting for Automotive Components?

The preference for aluminium in automotive die casting stems from its lightweight, high strength, and ability to form complex shapes with precision. Its thermal properties also make it ideal for components that require heat resistance.

- Environmental Impact: Aluminium’s recyclability supports sustainable manufacturing practices.

- Versatility: Suitable for a wide range of automotive applications.

- Performance: Enhances vehicle efficiency and reduces emissions.

How Does Aluminium Die Casting Contribute to Automotive Industry Efficiency?

Aluminium die casting contributes significantly to automotive industry efficiency by reducing vehicle weight, thereby improving fuel economy and reducing emissions. The process also allows for the integration of multiple functions into a single casting, enhancing production efficiency.

The high-speed production capability of aluminium die casting aligns with the automotive industry’s demand for high-volume production without compromising quality or performance.

Conclusion

This comprehensive guide to aluminum casting covers every aspect of the process, from the basics to advanced techniques. By adhering to best practices and focusing on quality and sustainability, we can achieve superior aluminum castings for a wide range of applications.

Drop me an email with your ideas, and I’ll get back to you swiftly!