Hi, I’m Lai Haijiang, owner of Yongzhu Die Casting since 2004. Passionate about aluminum die-casting? Let’s chat! We craft custom aluminum parts for various industries and offer both manufacturing and wholesale services. Interested in being our overseas agent? Drop me an email with your ideas, and I’ll get back to you swiftly!

Aluminum Die Casting Applications in Home Appliances

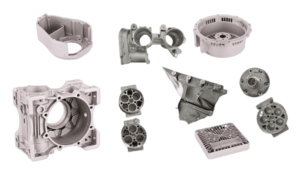

The use of aluminum die casting in home appliances represents a significant shift towards more efficient, durable, and cost-effective manufacturing processes.

Aluminum die casting is pivotal in manufacturing components for refrigerators, air conditioners, washing machines, and ovens, offering a blend of lightweight properties with high strength and thermal conductivity.

- Refrigerators: Die-cast aluminum plays a critical role in enhancing cooling mechanisms and structural integrity.

- Air Conditioners: Its thermal properties improve efficiency and performance in heat exchange components.

- Washing Machines: Aluminum die casting contributes to the durability and overall weight reduction of washing machines.

- Ovens and Microwaves: It ensures even heat distribution and withstands high temperatures.

Manufacturing Processes and Technological Advances

Advancements in die casting technologies have improved the quality and capabilities of aluminum components in home appliances, addressing previous limitations such as porosity and thermal fatigue.

- Basic Principles and Advantages of Die Casting: Exploring how the process meets the demand for complex shapes and fine details.

- Innovations in Aluminum Die Casting: Highlighting new techniques that enhance product quality and reduce waste.

Environmental Impact and Sustainability

The aluminum die casting process supports sustainability goals through recyclability and energy efficiency, aligning with the global push towards greener manufacturing practices.

- Recycling and Environmental Benefits: The significance of aluminum’s recyclability in reducing the environmental footprint.

- Energy Efficiency in Manufacturing: How die casting contributes to energy savings during production.

Market Trends and Future Outlook

The demand for aluminum die casting in home appliances is influenced by market trends towards more sustainable and efficient products. Future advancements may include the use of alloy combinations and process innovations to meet these needs.

Case Studies: Aluminum Die Casting in Home Appliances

Examining real-world examples provides insights into the successful application of aluminum die casting in the home appliance sector, offering lessons and inspiration for future projects.

Design Challenges and Solutions

Incorporating aluminum die casting into appliance design requires overcoming certain challenges, such as thermal management and achieving desired tolerances, through innovative engineering solutions.

- Thermal Management Solutions: Strategies for dealing with heat dissipation in high-performance components.

- Precision and Strength Enhancements: Approaches to improve the accuracy and durability of die-cast parts.

Conclusion

Aluminum die casting in home appliances signifies a leap towards greater efficiency, durability, and sustainability. This process enhances appliance performance, offering design flexibility and environmental benefits through recyclability.

For buyers and procurement professionals, recognizing these advantages is key to informed decision-making, promising a future where innovation and eco-friendly practices converge to redefine industry standards.

Drop me an email with your ideas, and I’ll get back to you swiftly!