Heat sinks play a critical role in thermal management for electronic devices, ensuring that components do not overheat and fail.

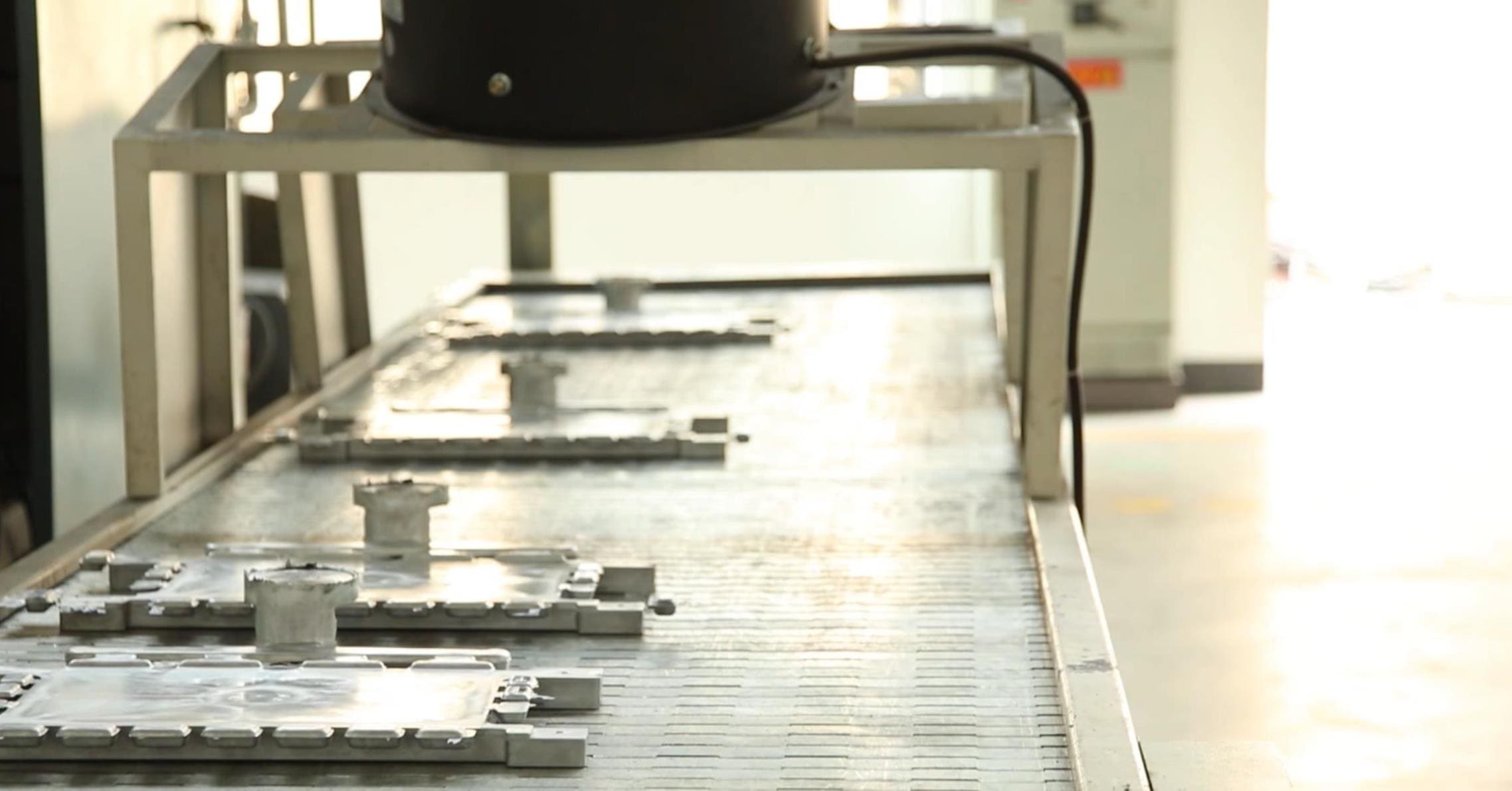

Aluminum die-cast heat sinks are widely used due to their excellent thermal conductivity, lightweight properties, and cost-effectiveness.

Advantages of Aluminum Die Cast Heat Sinks

High Thermal Conductivity

Aluminum’s high thermal conductivity allows for efficient heat dissipation, which is essential in preventing electronic components from overheating.

Lightweight

Aluminum is significantly lighter than other metals like copper, reducing the overall weight of electronic devices and improving portability.

Cost-Effective

Die casting is a cost-effective manufacturing process that allows for the production of complex shapes with high precision and repeatability. This results in lower production costs for heat sinks.

Corrosion Resistance

Aluminum naturally forms a protective oxide layer that prevents corrosion, making it suitable for various environments, including those with high humidity.

Design Considerations for Aluminum Heat Sinks

Fin Design

Optimizing the design of fins is crucial for enhancing the performance of heat sinks. Factors to consider include:

- Fin Spacing: Proper spacing allows for efficient airflow and heat dissipation.

- Fin Thickness: Balancing fin thickness with the need for maximum surface area.

- Fin Shape: Innovative shapes can improve airflow and heat transfer efficiency.

Surface Treatment

Applying surface treatments can further enhance the performance and durability of aluminum heat sinks:

| Anodizing | Powder Coating |

| Increases corrosion resistance and improves heat dissipation. | Provides an additional protective layer and can improve aesthetics. |

Integration with Devices

Ensuring that heat sinks are properly integrated with electronic devices is essential for optimal performance:

- Mounting Mechanisms: Secure attachment to components to ensure efficient heat transfer.

- Thermal Interface Materials (TIMs): Use of TIMs like thermal paste or pads to improve thermal conductivity between the heat sink and the component.

Applications of Aluminum Die Cast Heat Sinks

Aluminum die-cast heat sinks are used in a variety of applications due to their versatility and performance:

| Consumer Electronics | Industrial Equipment | Automotive | Telecommunications |

| Smartphones, laptops, tablets. | Power supplies, motor drives, LED lighting. | Electric vehicle components in-car entertainment systems. | Network servers base stations. |

Conclusion

Aluminum die-cast heat sinks offer high thermal conductivity, lightweight properties, and cost-effectiveness make them a preferred choice across various industries.

By considering factors such as fin design, surface treatments, and proper integration, we can optimize the performance and longevity of their heat sinks.