Painting cast aluminum is a delicate process that, when done correctly, can greatly enhance the appearance and longevity of the material.

Cast aluminum is widely used in various industries, from automotive to construction, and painting it can add an extra layer of protection against corrosion and wear.

In this guide, we will provide comprehensive instructions on how to properly prepare, paint, and maintain cast aluminum for a lasting, high-quality finish.

Why Painting Cast Aluminum is Essential

Aluminum, while naturally corrosion-resistant, can still develop oxidation over time, particularly in harsh environmental conditions.

Painting cast aluminum provides an additional layer of protection against corrosion, improves resistance to UV rays, and enhances the aesthetic appeal of the material.

Furthermore, a painted surface is easier to clean and maintain over time, making it an ideal choice for both functional and decorative purposes.

Searching for High-Quality for Cast Aluminum Parts?

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings.

Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

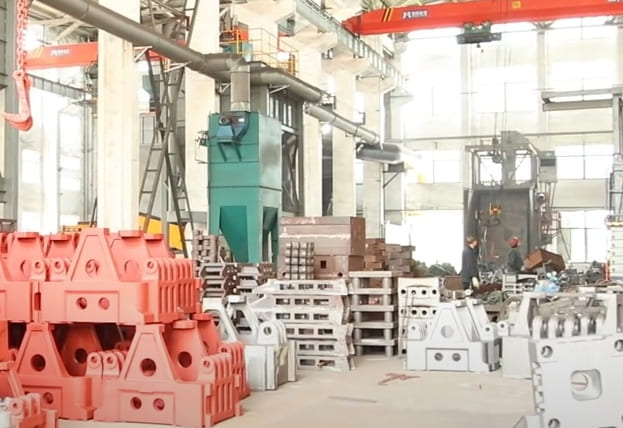

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis, 5-Axis, and 7-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency.

We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart.

We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.

Preparing Cast Aluminum for Painting

Proper surface preparation is the foundation of any successful painting job, especially for cast aluminum. Without the right preparation, the paint may not adhere correctly, leading to peeling or flaking over time.

1. Cleaning and Degreasing

Before painting, it’s critical to thoroughly clean the surface of the cast aluminum to remove oils, grease, and dirt.

- Tools Required: Use a mild detergent or aluminum-specific cleaner and a scrub brush.

- Technique: Scrub the aluminum surface to remove any contaminants. For tough stains, use a solvent like acetone or denatured alcohol to ensure all oils are removed. Rinse thoroughly with clean water and allow the surface to dry completely before moving to the next step.

2. Sanding the Surface

Sanding helps roughen the aluminum surface slightly, allowing the paint to adhere better.

- Tools Required: Sandpapers of various grits (starting at 200 and moving up to 600 grit for finer sanding).

- Technique: Use coarse sandpaper for initial sanding, and then switch to finer grits for a smooth finish. Be sure to sand evenly across the entire surface, focusing on edges and curves where paint adhesion can be more challenging.

3. Applying a Primer

Priming the cast aluminum surface is a vital step to ensure proper paint adhesion and to create a base that prevents corrosion.

- Tools Required: Aluminum-specific primer (etch primer or self-etching primer).

- Technique: Apply the primer in light, even coats using a spray gun or aerosol. Allow each coat to dry according to the manufacturer’s instructions, typically 10-15 minutes between coats. Two to three coats are recommended for optimal coverage.

Choosing the Right Paint for Cast Aluminum

Not all paints are suitable for aluminum. The best types are those designed specifically for metal surfaces, which provide better adhesion, durability, and resistance to weathering.

1. Types of Paint to Use

- Enamel Paint: Offers a glossy, durable finish and is ideal for outdoor applications.

- Acrylic Paint: Dries quickly, offers good UV resistance, and is ideal for decorative finishes.

- Epoxy Paint: Provides excellent adhesion and is often used for industrial applications where extra durability is needed.

2. Application Techniques

- Spray Painting: Provides the smoothest and most even coverage for aluminum surfaces.

- Brush Painting: Suitable for smaller areas or touch-ups, but care must be taken to avoid brush marks.

Painting the Cast Aluminum Surface

Once the surface has been cleaned, sanded, and primed, it’s time to apply the paint. Follow these steps for best results:

1. Apply Thin Coats

Always apply thin, even coats of paint to avoid drips and uneven coverage.

- Tools Required: Spray gun or aerosol spray paint.

- Technique: Hold the spray can or gun approximately 10-12 inches away from the surface, moving in a steady, sweeping motion. Allow each coat to dry fully before applying the next coat. Typically, two to three coats are sufficient.

2. Drying Time and Curing

Allow the paint to dry between coats and after the final application. Depending on the type of paint used, drying times can range from 30 minutes to several hours.

- Recommended Drying Time: 1-2 hours between coats, with a full cure taking up to 24-48 hours. Check the paint manufacturer’s recommendations for specific drying times.

Sealing and Protecting the Painted Surface

After painting, applying a clear protective coating helps to ensure the longevity of the paint job.

This is especially important for aluminum exposed to harsh conditions, such as outdoor or automotive applications.

1. Applying a Clear Coat

A clear coat adds an extra layer of protection against moisture, UV rays, and physical wear.

- Tools Required: Clear lacquer or polyurethane finish.

- Technique: Apply the clear coat in light, even layers using a spray can or spray gun. Allow each coat to dry before applying the next, and consider adding two to three coats for maximum durability.

2. Maintaining the Painted Surface

To keep the painted cast aluminum in excellent condition, follow these maintenance tips:

- Regular Cleaning: Use mild soap and water to clean the surface regularly. Avoid harsh chemicals or abrasive cleaning tools that can damage the paint.

- Inspect for Damage: Regularly inspect the surface for any chips, cracks, or peeling. Repair any damaged areas immediately by lightly sanding the affected area, applying primer, and repainting as needed.

- Waxing: For outdoor aluminum, consider applying a wax or sealant to further protect the painted surface from environmental wear.

Common Pitfalls and How to Avoid Them

1. Poor Paint Adhesion

If the paint fails to adhere properly, it’s likely due to insufficient surface preparation. Ensure the aluminum is thoroughly cleaned and sanded, and always use a primer designed for metal surfaces.

2. Drips and Uneven Coverage

Thick coats of paint are a common cause of drips. Always apply thin coats and let them dry fully between applications.

3. Peeling Paint

Peeling is often caused by poor surface preparation or using the wrong type of paint. Ensure you’re using paint designed for aluminum, and always apply a primer.

Applications of Painted Cast Aluminum

Painting cast aluminum is used in a variety of industries and applications, including:

- Automotive: Bumpers, wheels, and engine parts are often painted to enhance both appearance and durability.

- Architectural: Aluminum doors, windows, and decorative panels benefit from painting to match the aesthetic of a building while providing protection against the elements.

- Marine: Aluminum boats and marine equipment are painted to withstand harsh saltwater environments.

- Household Items: Furniture, lighting fixtures, and other aluminum household items can be painted to match the décor while ensuring a long-lasting finish.

By mastering the techniques of painting cast aluminum, you can significantly enhance the appearance and longevity of your aluminum components.

Proper preparation, the right choice of paint, and regular maintenance ensure that your painted surfaces remain vibrant and durable for years to come.

FAQ

1. Why is it important to paint cast aluminum?

Painting cast aluminum adds an extra layer of protection against corrosion, improves durability, and enhances the appearance of the material, especially for outdoor and industrial applications.

2. What kind of paint should I use for cast aluminum?

Use metal-specific paints such as enamel, acrylic, or epoxy paint. These paints provide better adhesion, durability, and resistance to weather and wear compared to regular paints.

3. Do I need to prime cast aluminum before painting?

Yes, applying a self-etching or aluminum-specific primer is essential for ensuring proper paint adhesion and preventing corrosion.

4. How should I prepare cast aluminum before painting?

First, clean the surface thoroughly to remove grease and dirt, sand the surface to roughen it slightly, and then apply a primer for best results.

5. Can I use spray paint on cast aluminum?

Yes, spray paint is a popular choice for cast aluminum as it provides even coverage and a smooth finish. Ensure the paint is suitable for metal surfaces.

6. How many coats of paint should I apply to cast aluminum?

It’s recommended to apply two to three thin coats of paint, allowing each coat to dry fully before applying the next for a smooth and durable finish.

7. How long does the paint take to dry on cast aluminum?

The drying time varies depending on the type of paint, but generally, it takes 1-2 hours between coats and up to 24-48 hours for a full cure.

8. Do I need to apply a protective clear coat after painting?

Applying a clear coat is recommended for additional protection against moisture, UV rays, and physical wear, especially for outdoor or high-use applications.

9. How can I prevent the paint from peeling off cast aluminum?

Proper surface preparation (cleaning, sanding, and priming) and using metal-specific paint will ensure strong adhesion and prevent peeling.

10. How should I maintain painted cast aluminum surfaces?

Clean painted surfaces regularly with mild soap and water, avoid using harsh chemicals, and inspect for any chips or damage to repaint promptly if necessary.