Aluminum density ≈ 2.70 g/cm³ (2700 kg/m³, 0.0975 lb/in³) at 20 °C.

Aluminum is popular because it is light, strong enough for many applications, and easy to cast or machine. When engineers start a new part, one of the first checks is weight, and weight starts with density.

For any specific alloy—especially die-casting grades such as A380, ADC12, AlSi10Mg—values shift slightly. The sections below explain what changes and give you full tables you can trust for early design and RFQs.

Conversions you might need

Use the same units end-to-end and life gets easier. 1 g/cm³ = 1000 kg/m³ = 0.0361273 lb/in³.

Weight = Density × Volume. If your CAD gives volume in cm³, multiply directly by g/cm³ to get grams.

Why density changes

Density is not a fixed “property of aluminum” but a result of how tightly atoms pack in a given alloy and condition.

- Alloying elements (Si, Cu, Mg, Zn) replace some aluminum atoms and change the packing—usually by a few percent.

- Temperature expands the lattice, so hot material is very slightly less dense. Tables generally assume ~20 °C.

- Casting porosity lowers the effective density of a finished part; foundry process control (gating, venting, vacuum) matters.

These effects are small but real, which is why different datasheets can differ by ~±0.02 g/cm³.

Die-Casting Alloys

If you’re sourcing die-cast parts, start here. The table puts A380/ADC12/AlSi10Mg up front because they cover most lighting housings, enclosures, brackets and decorative parts. Values are typical at ~20 °C and good for early weight estimates. For certification or FEA, confirm with your final supplier specification.

| Alloy | Density (g/cm³) | Density (kg/m³) | Density (lb/in³) | Notes |

|---|---|---|---|---|

| Pure Aluminum (ref) | 2.70 | 2700 | 0.0975 | Commercially pure, ~20 °C |

| A360 | 2.66 | 2660 | 0.0961 | Good fluidity, decent ductility |

| A380 / 380.0 | 2.73 | 2730 | 0.0985 | Most common die-casting grade |

| A383 / 383.0 | 2.74 | 2740 | 0.0989 | Better fill than A380 for thin walls |

| ADC12 (JIS) | 2.74 | 2740 | 0.0989 | JIS counterpart widely used |

| AlSi10Mg (die-cast) | 2.68 | 2680 | 0.0967 | Often chosen for strength/corrosion |

| AlSi9Cu3 | 2.72 | 2720 | 0.0982 | Automotive staple |

| 356.0 (AlSi7Mg0.3) | 2.68 | 2680 | 0.0967 | Sand/perm-mold reference; die-cast close |

| 413.0 (AlSi12) | 2.68 | 2680 | 0.0967 | Excellent fluidity |

| 319.0 (AlSi5Cu3) | 2.73 | 2730 | 0.0985 | General-purpose casting |

| A413.0 (AlSi12Cu2) | 2.66 | 2660 | 0.0961 | High-silicon, low shrinkage |

How to use this table quickly:

If your CAD shows 120 cm³, an A380 part weighs roughly 2.73 × 120 ≈ 328 g. Switching to AlSi10Mg (2.68 g/cm³) trims about 6 g with the same volume—small, but sometimes enough to hit shipping or handling thresholds.

Wrought Alloys (1000–7000) with the usual suspects

Extrusions and machined plates are specified by wrought grades. Even though temper (T5, T6) changes strength, it hardly moves density, so a single value per grade is practical for design estimates. Below are the common series plus the fast-lookup alloys buyers search most—6061 and 7075.

| Alloy | Density (g/cm³) | kg/m³ | lb/in³ |

|---|---|---|---|

| 1050 | 2.71 | 2710 | 0.0979 |

| 1060 | 2.71 | 2710 | 0.0979 |

| 1100 | 2.71 | 2710 | 0.0979 |

| 2014 | 2.80 | 2800 | 0.1012 |

| 2017 | 2.78 | 2780 | 0.1003 |

| 2024-T3 | 2.78 | 2780 | 0.1003 |

| 2219 | 2.84 | 2840 | 0.1028 |

| 3003 | 2.73 | 2730 | 0.0985 |

| 3004 | 2.73 | 2730 | 0.0985 |

| 3105 | 2.73 | 2730 | 0.0985 |

| 5005 | 2.70 | 2700 | 0.0975 |

| 5052 | 2.68 | 2680 | 0.0967 |

| 5083 | 2.66 | 2660 | 0.0961 |

| 5086 | 2.66 | 2660 | 0.0961 |

| 5454 | 2.69 | 2690 | 0.0973 |

| 5754 | 2.67 | 2670 | 0.0963 |

| 6005 / 6005A | 2.70 | 2700 | 0.0975 |

| 6060 | 2.70 | 2700 | 0.0975 |

| 6061-T6 | 2.70 | 2700 | 0.0975 |

| 6063-T5 | 2.70 | 2700 | 0.0975 |

| 6082-T6 | 2.70 | 2700 | 0.0975 |

| 7005 | 2.78 | 2780 | 0.1003 |

| 7020 | 2.78 | 2780 | 0.1003 |

| 7049 | 2.84 | 2840 | 0.1028 |

| 7050 | 2.83 | 2830 | 0.1024 |

| 7075-T6 | 2.81 | 2810 | 0.1016 |

| 7475 | 2.81 | 2810 | 0.1016 |

Reading tip:

If you’re comparing 6061 vs 7075, the density difference is only about 4%, but the strength can be much higher for 7075. In other words, if your project is weight-critical, geometry and alloy selection for strength often matter more than density alone.

Aluminum vs other metals

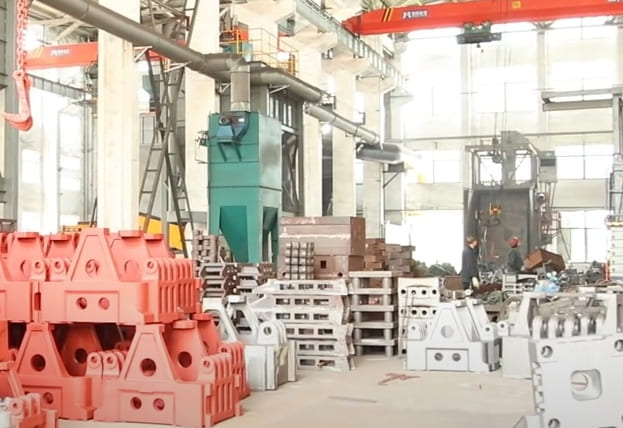

To see why aluminum wins in many housings and brackets, compare typical densities: Aluminum ~2.70, Magnesium ~1.74, Steel ~7.85, Copper ~8.96 g/cm³. Magnesium is lighter but harder to cast for thin-wall decorative parts and has different corrosion behavior. Aluminum hits the sweet spot of weight, cost, corrosion resistance and surface finishing—especially for outdoor lighting parts we build on 800–2000-ton die-casting machines.

Practical checklist before you lock the number

- Use 20 °C values unless your spec says otherwise.

- Check the actual alloy and standard (A380 vs ADC12 vs AlSi10Mg). Nominally close alloys still differ in density and properties.

- For as-cast parts, remember porosity can lower effective density slightly; machining chips will weigh per the table, but your net-part weight includes internal voids.

- For mass-production estimates, keep a ±2% guard band until first articles confirm real weights.

Notes & references

Values are typical handbook/datasheet numbers at ~20 °C and suitable for early design and quotation. For qualification, use the exact supplier spec for your batch.

Need help choosing between A380, ADC12 and AlSi10Mg for your part?

Send us your drawing—we’ll recommend the alloy and gating plan and quote quickly.