When choosing a new energy control box, it’s important to understand its manufacturing process and application areas. Specifically, aluminum low-pressure die casting plays a crucial role in producing these boxes.

Today, I’ll take you through how to select the right energy control box, especially those made using aluminum low-pressure die casting.

What is Aluminum Low-Pressure Die Casting?

Aluminum low-pressure die casting is a process where aluminum alloy is injected into a mold under low pressure to form a solid part.

Compared to other casting methods, this process produces parts with higher precision and better quality. It’s particularly suitable for making products that need to be durable and strong, such as control boxes.

This casting method ensures that the control box can maintain high efficiency and stable performance in various working environments.

Why Aluminum Alloy is Used in New Energy Control Boxes?

Aluminum alloy is the main material used for energy control boxes, offering several key advantages.

First, aluminum is lightweight but extremely strong, making it ideal for protecting sensitive components inside the control box, such as battery management systems, motors, and charging modules.

Aluminum also has excellent corrosion resistance and heat dissipation properties, which are essential for controlling temperature and ensuring the longevity of the control box in demanding conditions.

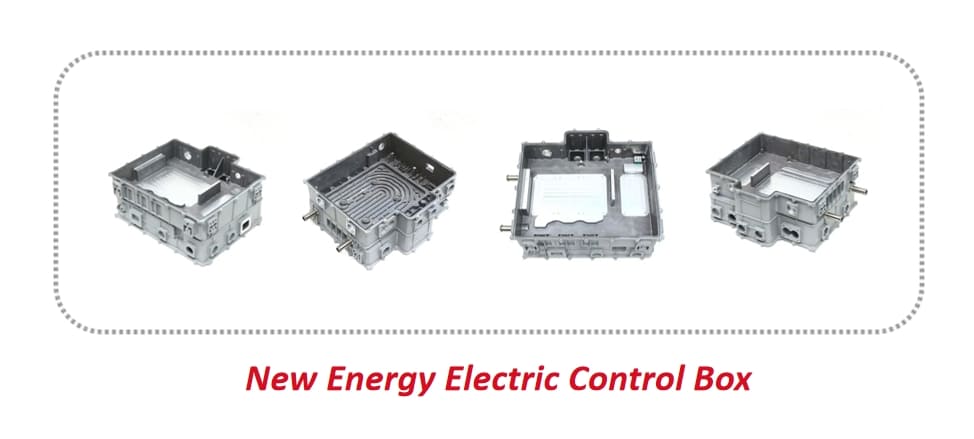

What is a New Energy Control Box?

A new energy control box is a critical component used in electric vehicles, energy storage systems, smart grids, and charging stations. It’s designed to protect and manage the electrical systems that drive these technologies.

By housing essential components like battery management systems and charging modules, it ensures that everything operates smoothly and safely.

A good control box will protect these systems from dust, water, and other environmental factors, making it an essential part of the infrastructure for new energy technologies.

What are the applications of the new energy control box?

1. Electric Vehicles (EVs): In electric vehicles, the energy control box manages the flow of electricity between the battery, motor, and other electrical systems. It ensures these components are protected and that the vehicle operates efficiently, especially under extreme conditions.

2. Energy Storage Systems: Energy storage systems, such as those used in solar power installations, rely on control boxes to regulate the charging and discharging of energy. These boxes ensure that the system operates safely, prevents overheating, and protects against electrical faults.

3. Smart Grids: In smart grids, energy control boxes help manage the distribution and flow of electricity. They ensure that electricity is efficiently routed, balancing supply and demand while preventing system overloads.

4. Charging Stations: Control boxes are also used in charging stations for electric vehicles. They manage the power flow during the charging process and ensure that everything operates safely, preventing potential electrical hazards.

How to Choose the Right New Energy Control Box?

When choosing a new energy control box, it’s crucial to consider several factors:

- Material Strength: Ensure the box is made from high-quality aluminum alloy for durability and protection.

- Heat Dissipation: Look for a box that has an efficient cooling system to prevent overheating.

- Water and Dust Resistance: The box should meet IP67 standards to ensure it can handle harsh environments.

- Customization: Depending on your specific needs, look for a manufacturer who offers customization options, including size, color, and additional processing.

By considering these factors, you can ensure that the energy control box you choose will provide long-term performance and reliability for your new energy applications.

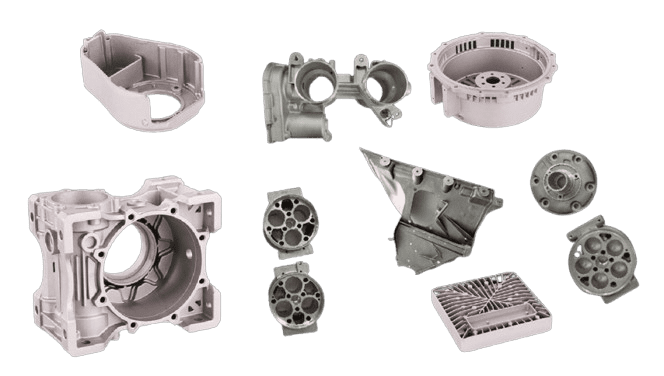

Searching for High-Quality for Cast Aluminum Parts?

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Zhejiang Yongzhu Casting Technology Co., Ltd.

Location: Zhejiang, China

Company type: Manufacturers, Producers, Wholesalers

Year Founded: 2004

Main Products: Aluminium die casting, Mold Making, Die Casting, Sand Casting, Gravity Casting

Leading Chinese producer Yongzhu Casting is formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

With 20 years of experience in the industry, we are a specialized manufacturer in Aluminum casting and Machining.

Our products are widely used in various applications such as Automotive, Energy, Lighting, Medical, Home Furnishings, Machinery & Equipment etc. Below are our advantages:

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings. Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis and 5-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency. We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart. We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.