Introduction

High Pressure Die Casting (HPDC) represents one of the most efficient and versatile manufacturing processes in modern metallurgy, particularly for aluminum components.

This advanced casting technique has revolutionized production across multiple industries, enabling the creation of complex, high-precision parts with excellent surface finishes and dimensional accuracy.

As global industries increasingly prioritize lightweight, durable, and cost-effective components, high pressure aluminum die casting has emerged as a cornerstone technology in manufacturing.

This comprehensive guide explores the intricacies of high pressure aluminum die casting, from the fundamental process mechanics to cutting-edge innovations that are reshaping the industry.

Whether you’re an engineer seeking technical insights, a procurement specialist evaluating manufacturing options, or a business leader exploring production capabilities, this article provides valuable information about this critical manufacturing process.

Understanding High Pressure Aluminum Die Casting

High pressure die casting is a manufacturing process that forces molten aluminum into a steel mold (die) cavity under significant pressure.

Unlike other casting methods, HPDC applies pressures typically ranging from 7,000 to 40,000 psi (50-300 MPa), enabling the production of thin-walled, complex geometries with excellent dimensional accuracy.

The HPDC process follows these key stages:

- Die Preparation: The steel die is prepared with release agents and preheated to optimal temperature.

- Metal Preparation: Aluminum alloy is melted in a furnace and maintained at the proper temperature.

- Injection: Molten aluminum is injected into the die cavity at high speed and pressure.

- Solidification: The metal solidifies under pressure, ensuring complete filling of the cavity and minimizing porosity.

- Ejection: The solidified part is ejected from the die using ejector pins.

- Finishing: The cast part undergoes trimming, machining, and other finishing operations as required.

Cold Chamber vs. Hot Chamber Die Casting

High pressure aluminum die casting primarily utilizes cold chamber machines due to aluminum’s tendency to attack the iron components in hot chamber systems. In cold chamber die casting:

- Molten aluminum is manually or automatically ladled into the injection chamber for each cycle

- The process is slightly slower than hot chamber but allows for higher melting point alloys

- Pressures can reach up to 4,500 kg/cm² (64,000 psi), significantly higher than hot chamber processes

- The separation of the melting unit from the injection system prevents metal contamination

High Vacuum Die Casting Process

An advanced variation of HPDC, high vacuum die casting represents a significant technological leap in aluminum casting technology. This process:

- Evacuates air from the die cavity before metal injection

- Dramatically reduces gas porosity in the final components

- Enables heat treatment of die cast parts without blistering

- Produces higher integrity structural components

- Allows for high-quality surface treatments including anodizing

The vacuum system typically achieves pressures below 50 mbar in the die cavity, removing oxygen that would otherwise create oxides and gas porosity.

This technology has been particularly transformative for automotive and aerospace applications requiring high-integrity structural components.

Equipment and Technical Capabilities

Modern HPDC Machine Systems

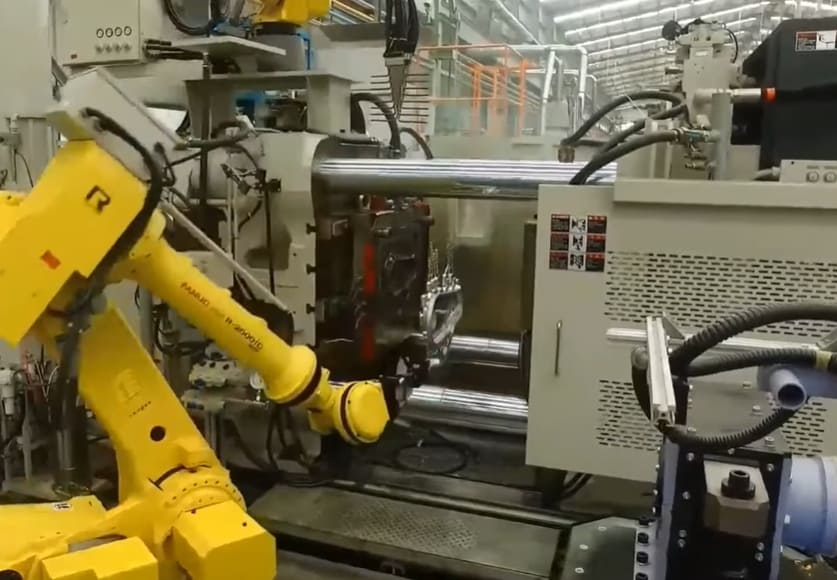

Today’s high pressure die casting machines represent sophisticated engineering systems with multiple integrated technologies:

- Clamping Systems: Modern machines feature hydraulic or toggle clamping mechanisms with locking forces ranging from 400 to over 4,000 tons

- Injection Systems: Advanced hydraulic or hybrid systems deliver precise control over injection parameters

- Control Systems: Computer-controlled interfaces manage all process parameters with real-time monitoring

- Automation: Robotic systems handle die lubrication, part extraction, and peripheral operations

The latest machines incorporate Industry 4.0 capabilities, including:

- Real-time process monitoring and adaptive control

- Predictive maintenance algorithms

- Digital twin technology for process optimization

- Remote monitoring and diagnostics

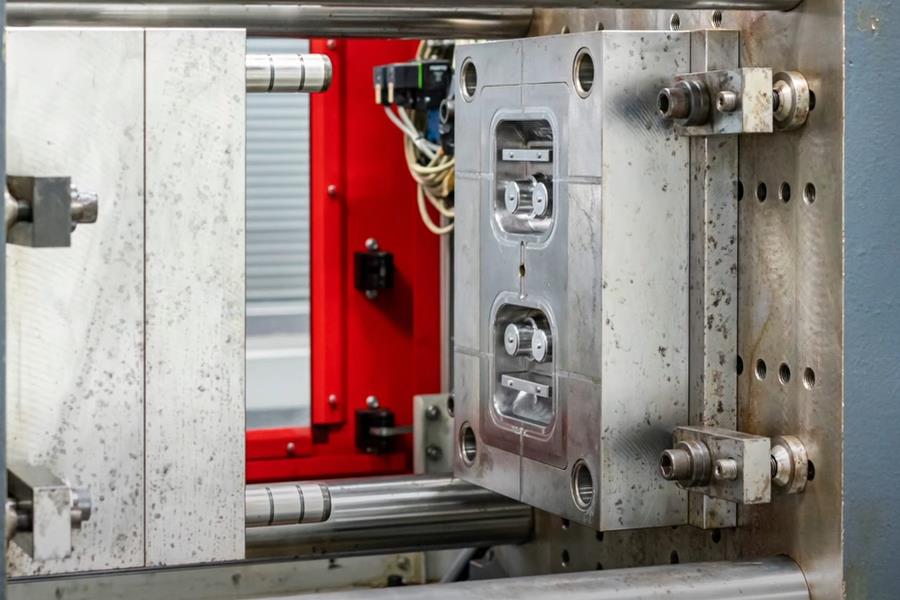

Multi-Cavity Die Casting Technology

Multi-cavity die casting represents a significant advancement in production efficiency, allowing:

- Simultaneous casting of multiple identical parts in a single shot

- Reduced production costs through increased throughput

- Consistent quality across all cavities through balanced runner systems

- Optimized material utilization and energy efficiency

Modern multi-cavity dies can accommodate 2-64 cavities depending on part size and complexity, though most production dies feature 2-8 cavities for optimal balance between productivity and quality control.

Thin-Wall Aluminum Casting Capabilities

One of HPDC’s most significant advantages is its ability to produce exceptionally thin-walled components:

- Wall thicknesses as low as 0.5-0.8mm are achievable in production environments

- Complex geometries with varying wall sections can be produced in a single shot

- Thin-wall technology enables significant weight reduction in automotive and electronic applications

- Advanced flow simulation software optimizes die design for thin sections

These capabilities have made HPDC the preferred manufacturing method for lightweight structural components, particularly in the automotive and electronics industries where weight reduction directly impacts performance and efficiency.

Applicable Aluminum Alloys

Common Die Casting Aluminum Alloys

Several aluminum alloy families are particularly well-suited for high pressure die casting:

A380 (AlSi8Cu3Fe): The most widely used die casting alloy, offering:

- Excellent fluidity and pressure tightness

- Good mechanical properties (tensile strength ~330 MPa)

- Moderate corrosion resistance

- Excellent machinability

ADC12 (AlSi10Cu2Fe): Popular in Asian markets, featuring:

- Superior fluidity for thin-wall applications

- Good wear resistance

- Moderate strength properties

- Excellent surface finish capabilities

A383 (AlSi10Cu3Fe): Modified version of A380 with:

- Improved pressure tightness

- Better resistance to hot cracking

- Enhanced fluidity for complex geometries

- Slightly reduced mechanical properties

A413 (AlSi12Fe): Silicon-rich alloy offering:

- Exceptional fluidity for intricate details

- Excellent corrosion resistance

- Lower strength than copper-containing alloys

- Superior pressure tightness

Alloy Selection for High Strength Applications

For applications requiring enhanced mechanical properties, specialized alloys have been developed:

Silafont-36 (AlSi9MgMn): Heat-treatable alloy offering:

- Excellent ductility (elongation >10%)

- High strength after T6 heat treatment (yield strength >220 MPa)

- Good corrosion resistance

- Suitable for structural automotive components

Castasil-37 (AlSi9MnMg): Developed for structural applications with:

- Excellent crash performance

- Good weldability

- High elongation values

- Suitable for safety-critical components

Magsimal-59 (AlMg5Si2Mn): Magnesium-rich alloy providing:

- High strength without heat treatment

- Excellent corrosion resistance

- Superior elongation properties

- Good energy absorption characteristics

The selection of the appropriate alloy depends on specific application requirements, including mechanical properties, corrosion resistance, thermal conductivity, and post-casting processing needs.

Semi-Solid Die Casting

Semi-solid die casting (also known as thixocasting or rheocasting) represents an innovative variation of the traditional HPDC process:

- Utilizes aluminum in a semi-solid state (30-40% solid fraction)

- Produces parts with significantly reduced porosity

- Enables the production of heat-treatable components

- Allows for welding and other secondary operations

- Results in improved mechanical properties

The semi-solid state creates a non-turbulent flow during injection, dramatically reducing gas entrapment and resulting in higher integrity castings.

This technology has gained significant traction for structural automotive components and aerospace applications where mechanical properties are paramount.

Typical Applications and Case Studies

Automotive Industry Applications

The automotive sector represents the largest market for high pressure aluminum die casting, with applications including:

EV Battery Housing: Electric vehicle manufacturers increasingly rely on HPDC for battery enclosures due to:

- Excellent electromagnetic shielding properties

- Superior thermal management capabilities

- Integrated cooling channels and mounting features

- Weight reduction compared to steel alternatives

- Crash energy absorption characteristics

Case Study: A leading European electric vehicle manufacturer reduced battery enclosure weight by 25% through the implementation of a large-format high vacuum die cast housing, integrating 70 previously separate components into a single casting while improving thermal management and crash performance.

Automotive Lightweighting Solutions: HPDC enables significant vehicle weight reduction through:

- Structural body components (shock towers, pillars)

- Powertrain components (transmission cases, engine blocks)

- Chassis components (control arms, subframes)

- Interior structural elements (seat frames, instrument panel supports)

Case Study: An automotive OEM achieved a 34% weight reduction in a front subframe assembly by converting from a multi-piece welded steel design to an integrated aluminum die casting, simultaneously reducing assembly costs by eliminating 27 separate components and 18 assembly operations.

Electronics Industry Applications

The electronics sector leverages HPDC for thermal management and structural components:

Die Cast Heat Sinks for LED Lighting: Modern LED lighting systems rely on aluminum die castings for:

- Optimized thermal dissipation through engineered fin designs

- Integrated mounting and optical positioning features

- Aesthetic exterior surfaces requiring minimal finishing

- Cost-effective production at high volumes

Case Study: A commercial lighting manufacturer reduced operating temperatures by 18°C in their high-output LED fixtures by implementing a custom die cast heat sink with optimized fin geometry and integrated fan mounting features, extending LED lifespan by approximately 40%.

5G Equipment Aluminum Housing: The telecommunications infrastructure for 5G networks utilizes HPDC components for:

- EMI/RFI shielding effectiveness

- Thermal management in high-density electronics

- Weather resistance in outdoor installations

- Integrated cooling features and mounting provisions

Case Study: A telecommunications equipment provider reduced base station enclosure weight by 37% while improving thermal performance through the implementation of thin-wall die cast housings with integrated cooling channels, enabling more compact installation footprints for urban deployments.

Aerospace Applications

The aerospace industry increasingly adopts high pressure die casting for non-critical components:

Aluminum Structural Components for Aerospace: Applications include:

- Interior structural supports

- Equipment mounting brackets

- Electronic enclosures

- Non-load-bearing structural elements

- Satellite components

Case Study: A satellite manufacturer reduced component weight by 22% and assembly time by 40% by converting a multi-piece sheet metal assembly to an integrated die casting for an electronics housing, simultaneously improving EMI shielding and thermal management.

Medical Industry Applications

The medical sector utilizes HPDC for equipment housings and structural components:

Medical Device Aluminum Enclosures: Applications include:

- Diagnostic equipment housings

- Surgical tool components

- Medical imaging equipment structures

- Laboratory equipment enclosures

Medical Grade Aluminum Die Casting: Specialized processes ensure:

- Biocompatibility where required

- Sterilization compatibility

- Precise dimensional control for equipment interfaces

- Excellent surface finish for easy cleaning

Case Study: A medical imaging equipment manufacturer reduced production costs by 28% while improving equipment reliability through the implementation of die cast structural components with integrated cooling channels and precise mounting features, replacing previously machined components.

Architectural Applications

The building and construction industry leverages HPDC for both functional and decorative elements:

Architectural Aluminum Die Cast Components: Applications include:

- Decorative façade elements

- Structural connection components

- Lighting fixtures and housings

- Window and door hardware

- Furniture components

Case Study: A luxury hotel development implemented custom die cast aluminum façade elements, reducing installation time by 60% compared to traditional fabricated components while achieving complex geometric designs that would be prohibitively expensive through other manufacturing methods.

Quality Control Processes

Comprehensive Quality Management

High pressure aluminum die casting requires rigorous quality control processes throughout production:

Pre-Production Quality Planning:

- Design Failure Mode and Effects Analysis (DFMEA)

- Process Failure Mode and Effects Analysis (PFMEA)

- Control plan development

- Capability studies and process validation

In-Process Quality Control:

- Real-time monitoring of critical process parameters

- Statistical Process Control (SPC) implementation

- Automated vision inspection systems

- Thermal imaging for die temperature verification

Post-Production Testing and Inspection:

- Dimensional verification using Coordinate Measuring Machines (CMM)

- X-ray inspection for internal defect detection

- Pressure testing for leak detection

- Mechanical property testing

- Surface finish evaluation

Reducing Porosity in Aluminum Die Casting

Porosity represents one of the most significant quality challenges in HPDC. Advanced techniques for porosity reduction include:

- Optimized gating and venting system design

- Controlled metal temperature and die temperature profiles

- Vacuum-assisted die casting technology

- Precise control of injection parameters (speed, pressure, profile)

- Advanced simulation software for flow and solidification optimization

Case Study: An automotive component manufacturer reduced porosity-related defects by 87% through the implementation of vacuum-assisted die casting technology combined with optimized gating design based on advanced flow simulation, enabling the successful production of heat-treatable structural components.

Die Casting Defects Prevention Guide

Common defects in aluminum die castings and their prevention strategies include:

Cold Shuts:

- Increase metal temperature

- Optimize gate locations and sizes

- Increase injection speed

- Improve venting

Porosity:

- Implement vacuum technology

- Optimize gating and venting

- Control metal quality (degassing)

- Adjust injection profile

Hot Tearing:

- Modify alloy selection

- Optimize cooling strategy

- Revise part design (wall thickness transitions)

- Adjust ejection timing

Dimensional Issues:

- Improve die temperature control

- Optimize cooling layout

- Enhance die design (proper draft angles)

- Implement SPC for process stability

Searching for High-Quality for Cast Aluminum Parts?

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Zhejiang Yongzhu Casting Technology Co., Ltd.

Location: Zhejiang, China

Company type: Manufacturers, Producers, Wholesalers

Year Founded: 2004

Main Products: Aluminium die casting, Mold Making, Die Casting, Sand Casting, Gravity Casting

Leading Chinese producer Yongzhu Casting is formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

With 20 years of experience in the industry, we are a specialized manufacturer in Aluminum casting and Machining.

Our products are widely used in various applications such as Automotive, Energy, Lighting, Medical, Home Furnishings, Machinery & Equipment etc. Below are our advantages:

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings. Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis and 5-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency. We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart. We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.