Among all casting defects that threaten aluminum die-cast quality, hot tearing (also called hot cracking) is one of the most destructive. It occurs when a casting begins to solidify but cannot withstand the internal tensile stresses generated during shrinkage and restraint. Unlike porosity or surface blisters, a hot tear is a structural fracture — once it forms, mechanical strength, sealing, and appearance are permanently compromised.

This guide explains what hot tearing is, why it occurs, how to identify it, and how to prevent it through alloy control, die design, and process optimization. All data and examples are drawn from real manufacturing practice at Yongzhu Casting.

What Is Hot Tearing in Aluminum Die Casting

Hot tearing is a crack formed during the final stage of solidification, when the semi-solid alloy cannot compensate for shrinkage stress between the solid and liquid phases.

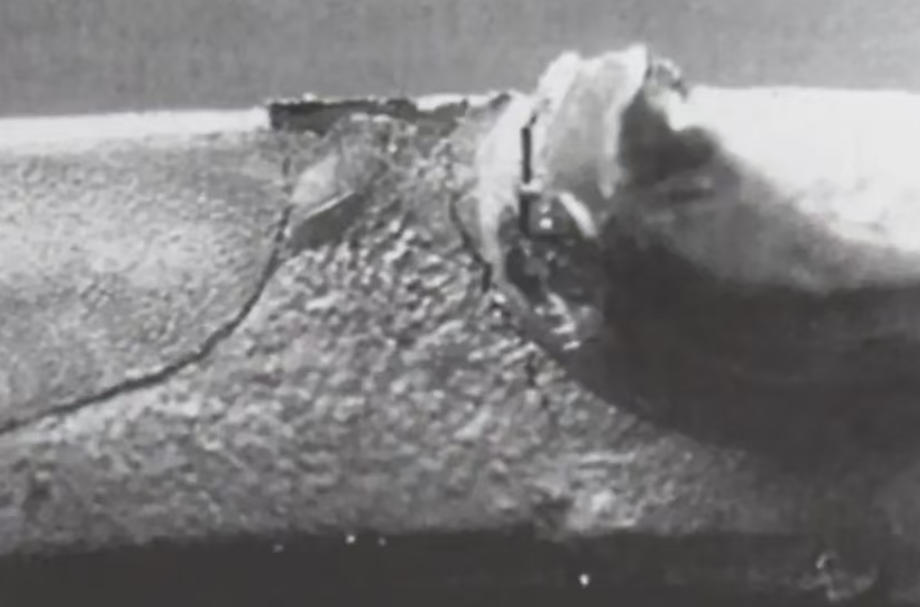

It typically appears:

- At thick junctions, ribs, or boss roots where contraction is restrained.

- Along grain boundaries, often in a wavy or branching shape.

- With oxidized, dull fracture surfaces, different from bright cold cracks.

Hot Tearing vs. Hot Cracking

In some literature the terms overlap. In die casting, hot tearing refers to fractures during solidification, while hot cracking usually refers to fractures after the part has mostly solidified, caused by residual thermal stress or poor ductility.

Both occur at high temperature, but hot tearing is a solidification-stage defect, and that is our focus here.

How Hot Tearing Happens (Metallurgical Mechanism)

During solidification, molten aluminum contracts by approximately 6.5% in volume.

When this contraction is uneven — due to temperature gradients, rigid die walls, or uneven cooling — tensile stress develops in the remaining semi-solid metal.

Key Factors

- Wide solidification range:

Alloys that solidify over a large temperature interval (e.g., 80–120 °C between liquidus and solidus) have a longer mushy zone, increasing risk. - High restraint:

Ribs, sharp corners, and thick-to-thin transitions limit free shrinkage. - Low ductility at semi-solid temperature:

When solid fraction ≈ 85–95%, the metal cannot deform plastically; any further contraction results in intergranular cracking. - Inadequate feeding:

If liquid metal cannot flow into the semi-solid region, the shrinkage gap becomes a tear.

In short: Stress > Strength → Crack.

How to Identify Hot Tearing

| Observation | Characteristics | Meaning |

|---|---|---|

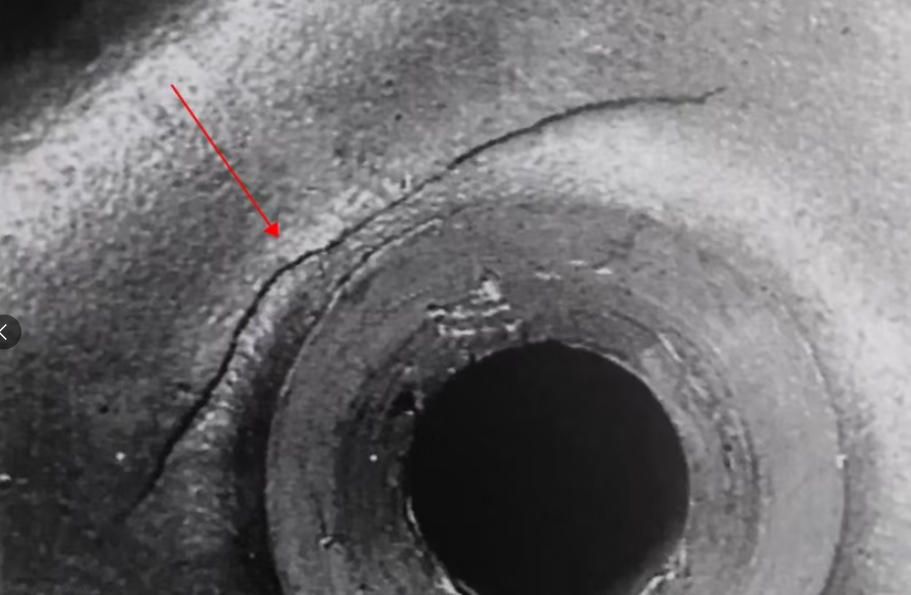

| Macroscopic | Long, branched cracks in thick sections; wavy or jagged fracture lines. | Thermal stress during solidification. |

| Fracture color | Dark gray or dull; often oxidized. | Exposed at high temperature. |

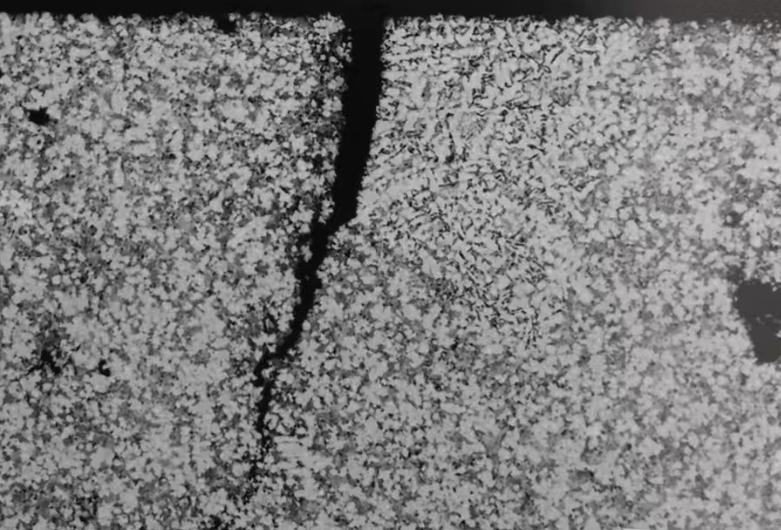

| Microscopic | Cracks follow grain boundaries, dendritic bridging visible. | Intergranular hot tear. |

| After alkaline etching | Cracks turn darker gray; appear continuous. | Useful for QC verification. |

| X-ray / CT | Linear voids in hot-spot areas (fillets, bosses). | Confirmation of internal tears. |

Hot tearing should be distinguished from cold cracks:

cold cracks show bright metallic color, straight edges, and occur after ejection or trimming.

Key Causes of Hot Tearing in Aluminum Die Casting

| Category | Typical Root Causes |

|---|---|

| Alloy Factors | ① Wide solidification range; ② Excess Mg, Cu, or Zn; ③ Low Si or excessive Fe/Na; ④ Coarse grains due to overheating; ⑤ Inclusion of low-melting impurities. |

| Mold & Thermal Design | ① Uneven wall thickness; ② Sharp corners or small fillets; ③ Hot spots lacking cooling; ④ Rigid cores or pins restraining shrinkage; ⑤ Mold temperature too high or too low. |

| Process Parameters | ① Injection speed too high or too slow; ② Overheating molten metal; ③ Excessive holding pressure or long dwell time; ④ Early ejection while metal still hot; ⑤ Die misalignment during opening. |

| Mechanical Stress | ① Core sticking or mis-alignment; ② Uneven ejection force; ③ Improper trimming; ④ Slider or pin wear causing offset. |

Hot Tearing Causes and Preventive Measures

| Cause | Observable Effect | Recommended Prevention |

|---|---|---|

| High solidification range (wide mushy zone) | Cracks at thick-thin transitions | Use alloys with narrow solidification range; add Si (6–10%) to improve feeding. |

| Excess Mg, Cu, Zn impurities | Brittle intermetallics at grain boundaries | Control composition: Mg < 0.5 %, Fe < 0.6 %, Cu < 3 %. |

| Uneven wall thickness / sharp corners | Stress concentration and restraint | Uniform wall design; increase fillet radius ≥ 3 mm. |

| Hot spots (poor cooling) | Thermal gradient → local stress | Add water channels; balance die temperature. |

| Overheating molten metal (> 720 °C) | Grain coarsening, oxidation | Pour at 660–690 °C; keep melt clean and degassed. |

| Mold temperature too high (> 280 °C) | Slow solidification; large thermal gradient | Maintain die surface 200–240 °C. |

| Long dwell / late ejection | Restrained shrinkage during solid phase | Optimize hold time; release when solidified but not over-constrained. |

| Core or pin sticking | Local tear during ejection | Polish core; apply uniform lubricant; ensure alignment. |

| Die misalignment or poor guide pins | Cracks near parting line | Re-install or calibrate die halves; inspect guide pins regularly. |

How to Prevent Hot Tearing

1. Alloy and Melt Control

- Choose alloys with narrow solidification range and good feeding ability (e.g., Al-Si 6–10 %).

- Keep hydrogen below 0.15 ml H₂/100 g Al; degas properly.

- Avoid contamination with Fe, Na, or Zn.

- Maintain melt temperature 660–690 °C and clean crucibles frequently.

2. Die Design and Thermal Balance

- Maintain uniform wall thickness; smooth transitions between sections.

- Increase fillet radius and avoid sharp ribs.

- Use balanced cooling lines near thick sections and gating area.

- Avoid excessive die temperature; target 200–240 °C for aluminum alloys.

- Add overflow wells to reduce metal turbulence and gas entrapment.

3. Process Optimization

- Tune injection parameters for steady flow:

- Filling ratio ≥ 70 %.

- Proper shot speed profile to minimize turbulence.

- Shorten holding time to reduce mold restraint, yet keep adequate pressure for feeding.

- Control lubrication: avoid water-rich sprays that create steam cracks.

- Ensure even ejection — all pins of equal length and alignment.

4. Structural and Thermal Compensation

- For hot-spot regions, add local cooling or chill inserts.

- For thin ribs attached to thick bases, add pressure-feeding sleeves or modify gating.

- Consider vacuum die casting to minimize gas and improve feeding.

- In severe cases, use direct-pressure squeeze casting or local pressurization pins.

Detection & Testing Methods

| Method | Description | Notes |

|---|---|---|

| Visual inspection | Check boss roots, corners, ribs for wavy cracks. | Always before trimming. |

| Alkaline etching test | Cracks turn dark gray under NaOH etch. | Quick in-house QC method. |

| X-ray / CT scan | Detect internal hot tears invisible outside. | For critical structural parts. |

| Metallographic analysis | Examine grain boundary oxidation and intergranular cracks. | Confirms hot tear vs. cold crack. |

| Simulation validation | Use Moldflow / ProCAST to visualize high-strain zones before tooling. | Preventive, design-stage measure. |

Simulation and Process Optimization

Modern simulation tools such as Moldflow, ProCAST, and P–Q² software can model filling, solidification, and stress.

Engineers can:

- Visualize temperature gradients and solidification sequence.

- Identify regions where solid fraction ≈ 90 % with high strain rate (critical for hot tearing).

- Adjust runner, gate, and cooling layout to balance temperature fields.

- Validate die design before cutting steel, saving cost and avoiding rework.

Why It Matters for Aluminum Die Casting Buyers

Hot tearing is not just a foundry problem — it affects end-use reliability.

- Cracks may propagate during machining or assembly, leading to part failure.

- Leakage or strength loss can compromise performance in automotive, lighting, or enclosure housings.

- Each scrapped part increases cost and lead time.

By working with suppliers like Yongzhu Casting, buyers can ensure optimized alloy control, verified process parameters, and simulation-based design review — preventing hot tearing before production.

Conclusion

Hot tearing is a complex but preventable defect.

Through balanced die design, controlled alloy chemistry, thermal management, and simulation-guided optimization, manufacturers can virtually eliminate hot tears even in high-volume aluminum die casting.

At Yongzhu Casting, every project includes material verification, simulation, and die-temperature monitoring to ensure consistent, crack-free castings.