Why Hot Cracking Matters

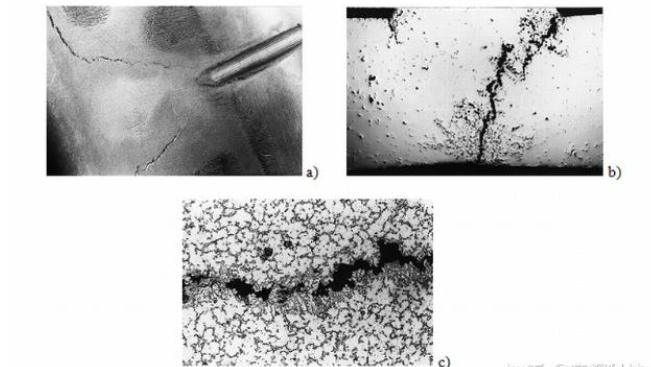

Hot cracking — sometimes called thermal cracking or solid-state cracking — is one of the most destructive defects in aluminum die casting. Unlike porosity or surface blisters, hot cracking is a structural fracture caused by thermal stress after solidification.

It appears when the casting is still hot but no longer fully molten, and internal contraction or mechanical restraint exceeds the metal’s remaining ductility.

In high-performance applications such as automotive housings, LED enclosures, and structural parts, hot cracking can lead to catastrophic failure during machining or assembly.

At Yongzhu Casting, we monitor every stage of the casting process — from melt temperature to die temperature control — to prevent these thermal fractures before they form.

What Is Hot Cracking in Aluminum Die Casting

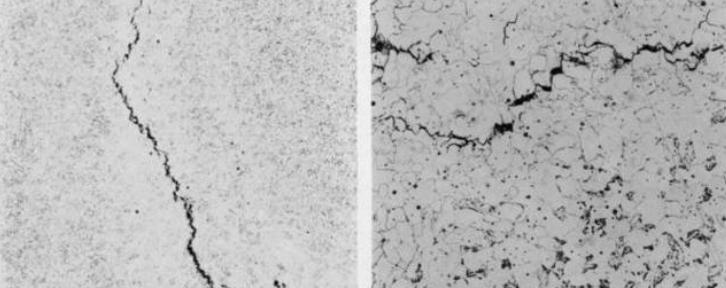

Hot cracking refers to fractures that occur after solidification begins but before the casting has fully cooled to room temperature.

At this stage, the metal is solid but still brittle due to internal stresses.

The cracks usually form:

- At thick-to-thin transitions, rib roots, or corners.

- Along grain boundaries where stress concentrates.

- With dull gray, oxidized fracture surfaces, unlike bright cold cracks.

It differs from hot tearing, which occurs during solidification (semi-solid phase).

Hot cracking happens slightly later — during the solid state cooling stage — when the part is being released from the die or restrained by thermal gradients.

How Hot Cracking Differs from Hot Tearing

| Feature | Hot Tearing | Hot Cracking |

|---|---|---|

| Stage of formation | During solidification (semi-solid phase) | After solidification, during cooling |

| Metal state | Mushy, partly liquid | Fully solid but still hot and brittle |

| Appearance | Dull, oxidized, wavy cracks along grain boundaries | Bright or dark straight cracks, often near corners or ribs |

| Main causes | Feeding failure, alloy shrinkage restraint | Thermal contraction, residual stress, mold misalignment, ejection stress |

| Typical location | Junctions, thick hot spots | Thin ribs, ejector pin marks, near bosses or cores |

| Prevention focus | Alloy composition, gating design, feeding | Mold alignment, temperature balance, ejection control |

In short:

→ Hot tearing = solidification-stage defect

→ Hot cracking = post-solidification, thermal stress defect

Typical Characteristics of Hot Cracking

- Appears as straight or slightly curved cracks, often in a network pattern.

- Fracture surface is partly oxidized but can have metallic luster at edges.

- Frequently found at sharp corners, ribs, ejector pin zones, and core attachments.

- May extend through the wall thickness or remain subsurface (internal).

- Under magnification, cracks often cut across dendritic grains, showing tensile failure.

Why Hot Cracking Occurs: Metallurgical Mechanism

When the casting cools after ejection, different sections shrink at different rates.

If this shrinkage is restrained — by the die, by core pins, or by uneven temperature fields — tensile stress builds.

Aluminum alloys lose almost 80% of their ductility between 350–450 °C.

If the stress at that stage exceeds the metal’s remaining tensile strength, the casting cracks.

Key Mechanisms:

- Thermal stress: uneven cooling between thick and thin walls.

- Mechanical restraint: tight cores, inadequate draft angles, or mold misalignment.

- Low hot ductility: due to excessive Fe, Cu, or Mg, or low Si content.

- Overheating: causes coarse grains, making the alloy brittle.

- Improper ejection: premature or uneven push from ejector pins.

Main Causes of Hot Cracking in Aluminum Die Casting

| Category | Typical Root Causes | Observable Effect |

|---|---|---|

| Alloy & Metallurgy | ① Low Si (< 6 %) → poor feeding; ② Excess Fe (> 0.6 %), Cu (> 3 %), or Mg (> 0.5 %) → brittleness; ③ Wide solidification range; ④ Coarse grain due to overheating | Fine cracks near junctions, low elongation |

| Mold Design & Cooling | ① Uneven wall thickness; ② Sharp transitions; ③ Poor cooling near cores; ④ Overheated die (> 280 °C); ⑤ Lack of stress relief fillets | Surface and subsurface cracks, mostly near ribs and corners |

| Process Parameters | ① Melt temperature too high (> 720 °C); ② Injection speed too fast; ③ Uneven lubrication (water-based spray too wet); ④ Early ejection; ⑤ Excessive holding pressure | Cracks after ejection or trimming |

| Mechanical Issues | ① Core misalignment; ② Uneven ejector force; ③ Mold offset or poor guide pins; ④ Trimming stress or vibration | Visible cracks at core root or ejector marks |

Areas Most Prone to Cracks

- Boss roots and rib intersections

- Frame corners and thin-wall junctions

- Around ejector pins or sleeves

- Large flat surfaces restrained by thick perimeters

- Edge transitions without proper fillets

Effects of Hot Cracking

- Leakage: through-wall cracks cause sealing failure.

- Reduced strength: tensile and fatigue strength drop by up to 40 %.

- Machining issues: cracks spread during CNC cutting.

- Cosmetic defects: visible lines after anodizing or powder coating.

- Increased rejection rate: repair is rarely economical.

Root Causes and Prevention Strategies

| Root Cause | Typical Sign | Engineering Solution |

|---|---|---|

| Uneven cooling / hot spots | Cracks near thick-to-thin transitions | Add water channels; balance die temperature (200–240 °C). |

| Alloy too brittle (low Si / high Fe-Cu) | Network cracks at corners | Adjust chemistry: Si 6–10 %, Fe < 0.6 %, Cu < 3 %. |

| Overheating melt | Dull cracks, coarse grains | Pour at 660–690 °C; avoid prolonged holding. |

| Mold misalignment | Single-sided cracks or offset fracture | Re-align die halves; inspect guide pins. |

| Premature ejection | Cracks near ejector pins | Delay ejection until part < 300 °C; use even ejector layout. |

| Rigid core design | Cracks near inserts | Use floating cores; increase draft angles. |

| Uneven lubrication | Cracks in local cold zones | Use uniform die spray; avoid water-rich lubricants. |

How Yongzhu Casting Prevents Hot Cracking

At Yongzhu Casting, our prevention strategy combines simulation, equipment precision, and real-time thermal control:

1. High-Precision Die Casting Equipment

- 800–2000 ton cold-chamber die casting machines handle large aluminum housings and structural parts.

- Equipped with die temperature controllers, maintaining 200–240 °C stability.

- Real-time pressure curve monitoring ensures consistent fill and holding phases.

2. Alloy Control and Melt Handling

- Each melt batch is analyzed for Si, Fe, Cu, and Mg via spectrometer.

- Degassing and filtration reduce hydrogen (< 0.15 ml H₂/100 g Al).

- Melt temperature maintained at 660–690 °C with ±5 °C tolerance.

3. Mold Design Optimization

- Smooth wall transitions, large fillet radii (≥ 3 mm).

- Floating cores and balanced ejector pins reduce restraint.

- Independent cooling circuits prevent local overheating.

4. Process Simulation and Verification

- Simulation tools such as ProCAST and P–Q² analysis predict hot-spot stress zones.

- Adjustments made before tooling to eliminate potential crack areas.

5. In-House Inspection

- X-ray and dye penetrant testing for high-stress components.

- Visual inspection for all production runs before machining.

- Defect mapping database to trace and prevent recurrence.

Repair and Prevention

Minor hot cracks may sometimes be removed by machining, but most require scrapping.

Thus, prevention is key.

Engineering recommendations:

- Maintain mold temperature uniformity within ±10 °C.

- Keep alloy composition within specification.

- Control ejection sequence; ensure uniform force.

- Periodically calibrate die alignment and cooling system.

- Use simulation to validate new designs before mass production.

Conclusion

Hot cracking is a thermal stress defect that forms after solidification, not during it.

It represents the metal’s inability to relieve contraction stress during cooling.

By optimizing alloy chemistry, die temperature balance, mold design, and ejection timing, hot cracks can be virtually eliminated.

At Yongzhu Casting, every mold design and production run undergoes simulation, die thermal control, and inspection to ensure castings meet structural and visual standards — free from both hot tearing and hot cracking.