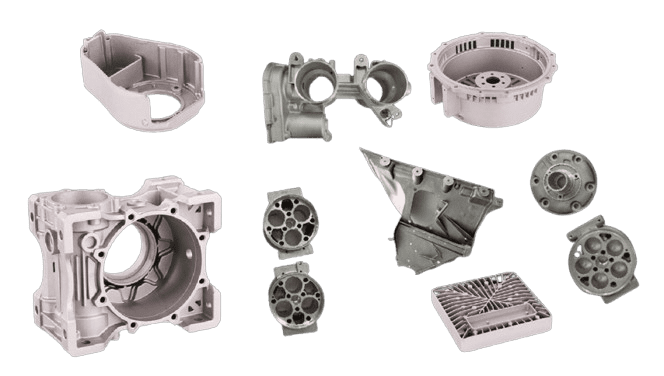

Aluminum spare parts play an indispensable role in modern manufacturing—from lighting housings and furniture hardware to automotive brackets and mechanical assemblies. Buyers choose aluminum for its light weight, strength, corrosion resistance, and design flexibility.

At Yongzhu Casting, we combine high-pressure die casting (HPDC), CNC machining, and advanced finishing to supply OEMs with durable, precision-made aluminum components. Acting as both a component supplier and spare parts factory, we deliver production consistency trusted by international brands.

What Are Aluminum Spare Parts?

Aluminum spare parts refer to functional or decorative replacement components made from aluminum alloys such as A380, ADC12, and AlSi9Cu3. These parts are designed for high-volume manufacturing where precision, heat resistance, and corrosion durability are critical.

Why aluminum dominates:

- Excellent strength-to-weight ratio for mechanical and structural parts

- Superior corrosion and oxidation resistance for outdoor applications

- Good thermal conductivity, ideal for lighting housings and enclosures

- Machinability and formability for complex geometries

Typical uses: lighting housings, furniture fittings, automotive mounts, electronic enclosures, and industrial brackets.

How Aluminum Spare Parts Are Manufactured

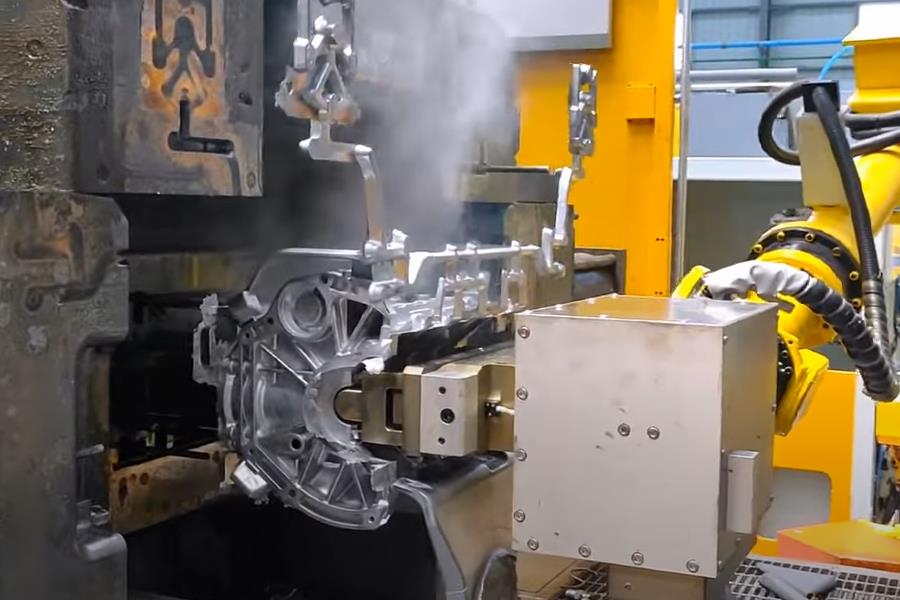

Step 1 – Die Casting (HPDC)

In high-pressure die casting, molten aluminum is injected into a steel mold at up to 2000 tons of pressure. This method ensures:

- Dimensional repeatability for large production volumes

- Smooth surface finish, ready for machining or coating

- Reduced porosity via controlled cooling and venting design

At Yongzhu Casting, we operate HPDC machines ranging from 800T to 2000T, producing both compact components and large, complex housings.

Step 2 – CNC Machining & Trimming

CNC machining refines critical features such as mounting holes, sealing grooves, and threaded connections.

Tight tolerance control (±0.05–0.2 mm) ensures accurate fitment during assembly — especially important for brackets and precision enclosures.

Step 3 – Surface Finishing

Finishing defines both the performance and appearance of spare parts.

Yongzhu provides multiple finishes depending on the end-use:

- Anodizing for corrosion protection and color uniformity

- Powder coating for weather resistance and visual appeal

- Polishing or shot blasting for smooth decorative surfaces

- Custom coatings for furniture or lighting hardware

Step 4 – Assembly & Export Packaging

Each finished batch undergoes full inspection and protective export packaging, including:

- Leak-proof and moisture-safe cartons

- English-labeled outer boxes

- Stacked export pallets

Ensuring that every delivery arrives ready for integration into OEM lines or global distribution.

Aluminum Spare Parts Comparing Manufacturing Methods

| Process | Typical Application | Advantages | Limitations |

|---|---|---|---|

| High Pressure Die Casting (HPDC) | Mass production of precision housings, brackets, and handles | Excellent repeatability, smooth surface, near-net shape | Higher tooling cost, limited for very large parts |

| CNC Machining | Low-volume, high-precision prototypes or assembly-critical features | Tight tolerances, flexible geometry | Slower, higher unit cost |

| Forging | Structural or load-bearing aluminum components | Superior mechanical strength | Limited shape complexity, requires post-machining |

| Sand Casting | Large industrial or custom parts | Lower tooling cost | Surface roughness, lower accuracy |

HPDC remains the preferred method for OEM aluminum spare parts because it offers the best balance between accuracy, speed, and scalability.

Aluminum Spare Parts in Global Supply Chains

In global sourcing networks, aluminum spare parts factories often serve as both component suppliers for OEMs and aftermarket producers.

- OEM suppliers focus on consistency, mold maintenance, and quality certifications (ISO 9001, IATF 16949).

- Aftermarket manufacturers emphasize flexibility, customization, and smaller-batch runs.

Yongzhu Casting bridges both roles, providing high-pressure die-cast aluminum components that meet international standards while maintaining competitive lead times and export documentation.

Key Applications Across Industries

Lighting Housings & Fixtures

Die-cast aluminum provides heat dissipation, sealing (IP65+ compliance), and design freedom for modern LED housings.

Yongzhu’s housings are engineered for outdoor, architectural, and industrial lighting, combining structural strength with aesthetic precision.

Furniture Hardware & Handles

Our aluminum handles, pulls, and brackets balance decorative appeal with mechanical integrity.

We offer multiple finishes—chrome, brushed, anodized, or powder-coated—designed to match diverse furniture and architectural styles.

Automotive & Machinery Brackets

Automotive brackets demand rigidity, vibration resistance, and fatigue performance.

Yongzhu employs optimized gating, pressure control, and CMM verification to ensure every bracket maintains mechanical strength and dimensional accuracy under long-term use.

Quality Control and Certifications

Every production stage at Yongzhu Casting is backed by a strict quality framework:

- CMM inspection for dimensional validation

- Helium leak and pressure testing for fluid-tight parts

- Salt-spray / corrosion testing for surface coatings

- Porosity control through gating optimization and real-time monitoring

- ISO 9001-certified quality management system for traceability and export compliance

These steps ensure defect-free performance and long-term reliability for global OEM customers.

Why OEM Buyers Choose Yongzhu Casting

- Full in-house process: HPDC, CNC, finishing, assembly

- 800–2000T die-casting machines for different component sizes

- Engineering DFM review before tooling

- Export-ready QC documentation and packaging

- Proven expertise across lighting, furniture, and automotive projects

Looking for a reliable aluminum spare parts supplier or OEM factory?

Send your drawings for a quick DFM review — we’ll help optimize your design before mass production.

Conclusion

From design review to final export, aluminum spare parts manufacturing demands engineering precision, surface quality, and supply reliability.

At Yongzhu Casting, we combine HPDC, machining, surface treatment, and ISO-certified quality control to deliver components that perform—and look—exactly as intended.

Need aluminum components that meet OEM standards?

Contact Yongzhu Casting today for engineering review, rapid sampling, and full-scale production support.