When engineers or OEM buyers plan aluminum spare parts, one question always arises:

Should this component be die-cast or CNC-machined?

Both processes deliver precision aluminum parts, but each follows a different philosophy.

Die casting is ideal for mass-produced complex shapes with repeatable quality,

while CNC machining is chosen for tight-tolerance or low-volume parts.

This guide compares both methods — cost, accuracy, surface quality, and production stages — based on Yongzhu’s real manufacturing experience.

Understanding the Two Processes

What Is Aluminum Die Casting?

Aluminum die casting (HPDC) is a high-pressure process that injects molten aluminum alloy into a steel mold cavity, creating complex parts with excellent surface finish and dimensional accuracy.

Yongzhu operates 800–2000 T HPDC machines, using alloys such as ADC12, A380, and AlSi9Cu3.

Step 1 — Alloy Selection & Melt Preparation

The process starts with choosing the right alloy, typically Al-Si or Al-Mg series, for the balance of strength, ductility, and corrosion resistance. Yongzhu melts virgin aluminum ingots and recycles only internal runners and rejected parts under strict control to reduce waste while maintaining alloy purity.

Molten metal is degassed with nitrogen or argon and grain refined for improved fluidity and reduced porosity.

Step 2 — Die Design & Fabrication

Each mold is engineered with proper gating, runners, and vents to ensure synchronized metal flow and rapid air evacuation. Dies are made from premium H13 tool steel with efficient thermal control channels. Draft angles, ribs, and fillets are optimized for easy ejection and extended tool life — typically up to 100,000 cycles or more with correct maintenance.

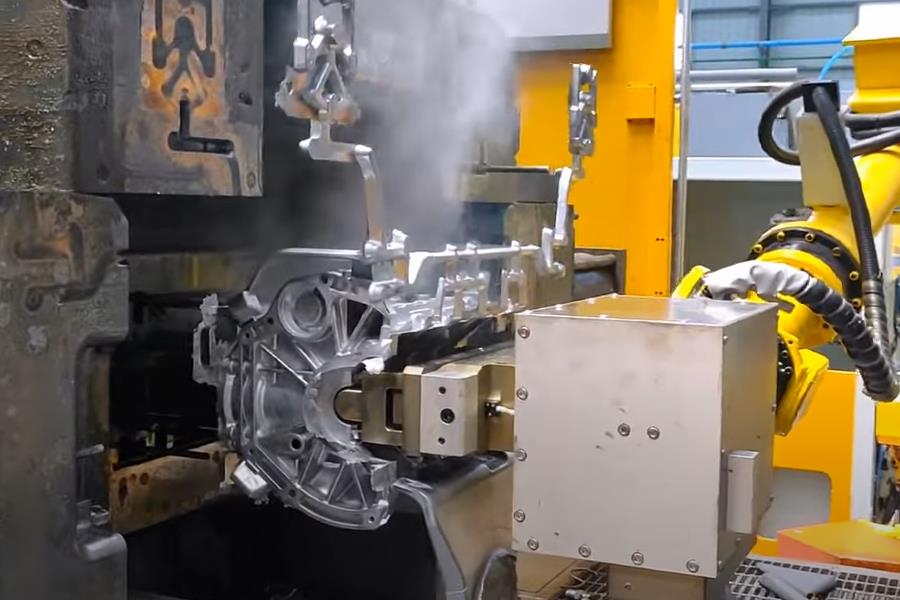

Step 3 — Die Casting Cycle

A typical HPDC shot includes die closing, lubrication, slow shot, fast shot (metal injection), intensification, solidification, and ejection.

The molten aluminum fills the cavity in milliseconds under high pressure and solidifies within seconds.

Cycle times range from a few seconds to under two minutes, depending on part geometry and wall thickness.

Step 4 — Solidification & Ejection

Proper die temperature control and intensification time prevent cold shuts, porosity, and flow marks. After solidification, ejector pins release the part from the die, and automatic trimming removes gates and flash.

Step 5 — Primary Finishing

Trimmed parts undergo shot blasting or tumbling for a uniform matte surface, followed by leak or pressure testing for functional housings.

Step 6 — Secondary Machining

Critical surfaces such as holes, threads, or sealing faces are CNC-machined for precise fit. This hybrid approach combines casting efficiency with machined accuracy, achieving final tolerances of ±0.05–0.10 mm where required.

What Is CNC Machining?

CNC machining is a subtractive process that removes material from solid aluminum blocks or pre-cast parts using computer-controlled tools. It’s ideal for low-volume, prototype, or ultra-precise parts.

3-Axis vs 5-Axis Machining

- 3-axis systems move along X, Y, and Z axes — best for flat planes, pockets, and simple contours.

- 5-axis systems add two rotary axes, enabling complex curved surfaces and multi-side machining in one setup, often used for lighting housings and automotive brackets.

Common CNC Operations

- Drilling: creates precise round holes for fasteners or alignment.

- Tapping: forms or cuts internal threads after drilling.

- Reaming: achieves a fine hole diameter and smooth finish.

- Boring: enlarges and trues existing holes for concentricity.

- Chamfering and deburring: removes sharp edges and burrs for better assembly fit and touch quality.

- Surface milling: controls flatness, parallelism, and surface texture.

CNC machining delivers tolerances as tight as ±0.01–0.05 mm and surface finishes up to Ra 0.4 µm, depending on tool quality and setup rigidity.

Cost Comparison — When Volume Changes Everything

| Factor | Die Casting | CNC Machining |

|---|---|---|

| Tooling Cost | $8 000 – $20 000 (one-time mold) | None |

| Unit Cost (High Volume) | Low after 500 pcs | High |

| Setup Time | Long (mold design & fabrication) | Short |

| Cycle Time | Seconds per shot | Minutes per part |

| Material Waste | 3–5% (internal re-melt) | 60–70% (chips) |

| Best for | Mass production | Prototyping or small batches |

👉 Takeaway: Die casting requires upfront tooling but becomes dramatically more cost-effective once production scales beyond several hundred parts. CNC machining remains ideal for low-volume, prototype, or tolerance-critical applications.

Dimensional Accuracy and Surface Tolerance

| Characteristic | Die Casting (As-Cast) | After CNC Finishing | Description |

|---|---|---|---|

| Dimensional Accuracy | ±0.2 mm typical for small features | ±0.05–0.10 mm common | HPDC parts achieve near-net-shape accuracy; CNC refines it for mating precision |

| Surface Roughness (Ra) | 1.0–2.5 µm | 0.4–1.6 µm | Die casting yields uniform matte surfaces; CNC provides mirror finishes |

| Feature Complexity | Excellent for thin walls, ribs, bosses | Ideal for precision holes, threads | Combined workflow maximizes efficiency |

| Repeatability | Excellent (mold-based) | High (tool-path controlled) | Each process offers consistent repeatability within its tolerance band |

When to Choose Each Process

| Requirement | Choose Die Casting | Choose CNC Machining |

|---|---|---|

| Production Volume | >500 pcs | <100 pcs |

| Geometry Complexity | Complex, thin-wall | Simple or thick-wall |

| Tolerance Priority | Moderate | Very tight |

| Material Options | Aluminum alloys | Aluminum, copper, steel |

| Example Application | Lighting housings, automotive brackets, furniture handles | Fixtures, prototypes, precision fasteners |

🔧 Example:

Yongzhu produces die-cast lighting housings in batches of 5,000+, ensuring thermal conductivity and IP sealing performance. Before mold investment, CNC prototypes are used to verify geometry and heat dissipation performance.

Surface Finishing and Quality Control

Both die casting and CNC machining rely on surface finishing to meet functional and aesthetic requirements.

Common Finishes for Aluminum HPDC Parts

- Anodizing — improves corrosion and wear resistance.

- Powder coating — offers decorative and durable protection.

- Conversion coating — used as a base for painting or electrical conductivity.

- E-coating / Painting — ensures even coverage and color uniformity.

Process Control & Inspection at Yongzhu

- CMM (Coordinate Measuring Machine) checks datums, true positions, and GD&T features with micrometer-level accuracy.

- Leak & pressure testing validates sealed housings and enclosures.

- X-ray / CT inspection detects internal porosity where required.

- Deburring & edge finishing follow defined specifications (0.2–0.5 mm edge break) with CMM sampling to verify feature stability.

All surface finishing operations are validated through salt spray or corrosion tests (e.g., ASTM B117) to meet customer standards.

Visual inspection is always complemented by dimensional confirmation, ensuring cosmetic and mechanical compliance.

Environmental and Material Policy

Yongzhu prioritizes both performance and sustainability:

- Only virgin aluminum ingots are used for new melts.

- Internal runners, flash, and defective castings are re-melted in a closed loop, keeping alloy chemistry stable.

- This process reduces material waste by more than 25% without compromising mechanical properties.

- No post-consumer recycled aluminum is used for critical OEM parts.

Application Examples

Lighting Housings

Thin-wall HPDC housings offer excellent heat dissipation and consistent coating surfaces. After casting, mounting surfaces are CNC-milled to achieve ≤0.10 mm flatness for LED module contact.

Furniture Hardware

Handles and decorative trims benefit from die-cast precision and smooth surfaces. CNC machining ensures tight fits for screw bosses and inserts, followed by anodizing or powder coating for durability.

Automotive Brackets

Die-cast aluminum brackets deliver high stiffness-to-weight ratios. Machined holes meet ±0.05–0.08 mm tolerances, verified by CMM for position and concentricity.

Final Decision — Finding the Right Balance

For mass production, die casting wins on cost, cycle time, and repeatability.

For small batches or prototypes, CNC machining ensures flexibility and fine detail.

Yongzhu often integrates both:

Die cast for volume → CNC finish critical zones → Inspect via CMM → Apply protective coating.

💬 Not sure which process suits your next aluminum part?

Send Yongzhu your drawing — our engineers will review manufacturability and highlight design improvements within 48 hours.