Hi, I’m Lai Haijiang, owner of Yongzhu Die Casting since 2004. Passionate about aluminum die-casting? Let’s chat! We craft custom aluminum parts for various industries and offer both manufacturing and wholesale services. Interested in being our overseas agent? Drop me an email with your ideas, and I’ll get back to you swiftly!

Why Does Aluminium Die Casting in China Stand Out?

China’s aluminium die casting industry is renowned for its large-scale production capabilities and advanced technology. This has positioned China as a global leader in providing high-quality and cost-effective aluminium die casting solutions.

The Chinese aluminium die casting sector benefits from a robust supply chain, skilled workforce, and continuous investment in research and development, ensuring innovative and efficient production methods.

How Can Blow Holes Be Prevented in Aluminium Die Casting?

Blow holes in aluminium die casting are a common defect that can be minimized by controlling the molten aluminium’s temperature and by employing vacuum die casting techniques.

- Proper Temperature Management: Ensuring the aluminium is at the optimal temperature for casting reduces the risk of blow holes.

- Vacuum Die Casting: This method helps in removing gases from the molten metal, preventing blow hole formation.

- Quality Control Measures: Regular inspection and testing of castings for integrity and porosity can significantly reduce the occurrence of blow holes.

What Do Buyers Look for in Aluminium Die Cast Products?

Buyers prioritize quality, precision, and durability in aluminium die cast products. They seek suppliers who can provide consistent quality and reliability in their products.

Cost-effectiveness and timely delivery are also crucial factors for buyers. They value suppliers who can offer competitive pricing without compromising on quality or lead times.

Why Are Aluminium Die Cast Brackets Preferred in Manufacturing?

Aluminium die cast brackets are favored for their strength, lightweight, and resistance to corrosion, making them ideal for a wide range of manufacturing applications.

- Durability: Aluminium brackets withstand harsh environments and heavy usage.

- Versatility: Suitable for various applications, from automotive to industrial machinery.

- Cost-Efficiency: Aluminium brackets are more cost-effective compared to other materials, offering long-term savings.

What Are the Benefits of Using Aluminium in Die Casting?

Aluminium is a preferred material in die casting due to its lightweight nature, high strength-to-weight ratio, and excellent thermal and electrical conductivity.

- Lightweight: Reduces overall product weight, enhancing efficiency in applications like automotive parts.

- High Strength: Offers the necessary durability for demanding applications.

- Thermal and Electrical Conductivity: Ideal for components in electrical and heat exchange applications.

Where Can You Find Aluminium Die Casting Buyers in the CHINA?

Buyers of aluminium die casting in China can be found in various sectors such as automotive, electronics, and industrial machinery.

Trade fairs and online B2B platforms are effective channels for connecting with these buyers.

How Does Aluminium Die Casting Offer Advantages Over Other Methods?

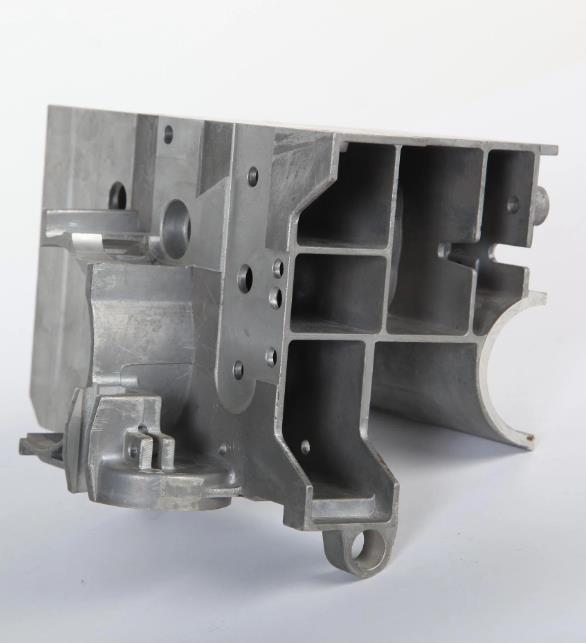

Aluminium die casting is favored over other methods for its ability to produce complex shapes with high precision and excellent surface finish. This method is also known for its rapid production rate and cost efficiency.

The versatility of aluminium die casting allows for the production of a wide range of parts, from small components to large structural elements, accommodating diverse industry needs.

What Makes Aluminium Die Cast Boxes Ideal for Certain Applications?

Aluminium die cast boxes are ideal for applications requiring durability, lightweight, and protection against environmental factors. They are commonly used in electronics, automotive, and outdoor applications.

- Environmental Resistance: Provides protection against moisture, dust, and temperature variations.

- Lightweight and Strong: Enhances portability without compromising on strength.

- Customizability: Can be designed to meet specific size and shape requirements.

Why Choose an Aluminium Die Cast Junction Box for Electrical Installations?

Aluminium die cast junction boxes are preferred in electrical installations for their durability, corrosion resistance, and excellent electrical conductivity. They provide reliable protection for electrical connections in various environments.

- Safety: Offers robust protection against fire hazards and electrical faults.

- Longevity: Resistant to corrosion, ensuring a longer lifespan.

- Versatility: Suitable for both indoor and outdoor installations.

The article explores aluminium die casting’s role in China, focusing on techniques to prevent defects here, buyer preferences, and advantages in manufacturing. It highlights the material’s benefits, industry trends, and the growing market for aluminium die cast products, particularly in electrical and automotive sectors.

Drop me an email with your ideas, and I’ll get back to you swiftly!