Do not confuse cast aluminum with extruded aluminum, which are two different classifications.

Discover the key differences between cast and extruded aluminum for optimized manufacturing decisions.

Discover the key differences between cast and extruded aluminum for optimized manufacturing decisions.

Aluminum die casting alloy guide for 2024—materials, properties, and industry applications in one detailed resource.

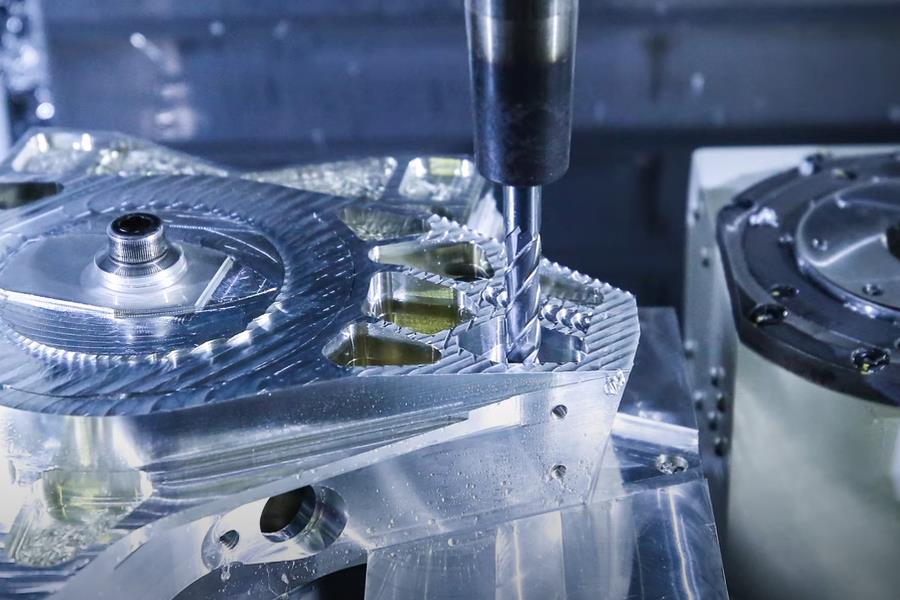

Guide to finding top CNC machine shops in the USA with tips on materials, services, and advanced capabilities.

Learn about aerospace casting processes, materials, benefits, and leading companies in this comprehensive 2024 guide.

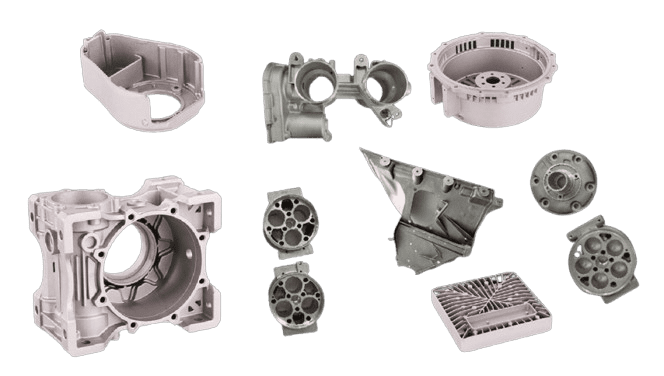

Aluminum die casting offers lightweight, strong, and intricate parts for industries like automotive and aerospace. Explore its processes and benefits.

Die-cast cars: History, collecting trends, prices, and creative uses in 2024, for hobbyists and enthusiasts.

Discover why design for manufacturing (DFM) is essential to enhancing production efficiency and quality.

Explore the USA’s top 15 high-pressure aluminum die-casting suppliers in 2024. This list highlights industry leaders providing precision components for automotive, aerospace, and more.

Discover the top aluminum alloys for die casting and how to choose the right one for your project.