The 6 Most Common Types of Aluminum Finishes

Learn the 6 most common aluminum finishes—anodizing, powder coating, chromate conversion, paint, mechanical finishing and E-coating—and how to choose the right one for cast parts.

Learn the 6 most common aluminum finishes—anodizing, powder coating, chromate conversion, paint, mechanical finishing and E-coating—and how to choose the right one for cast parts.

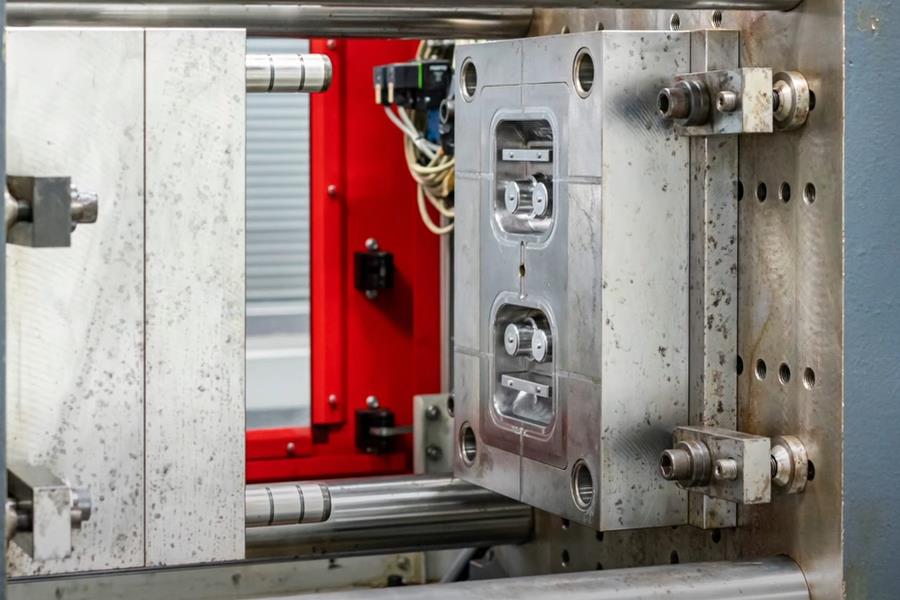

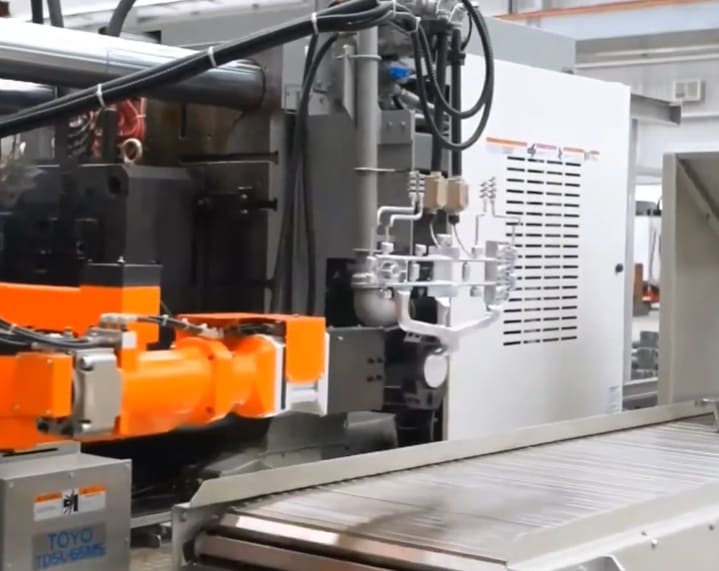

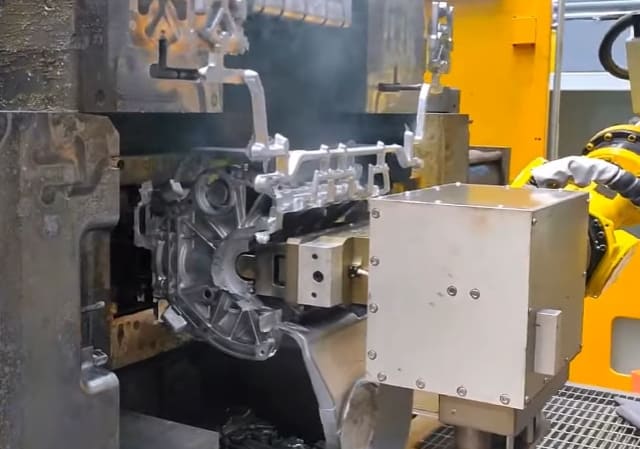

Compare Low, Medium, and High Pressure Die Casting methods. Understand their processes, benefits, and ideal applications for manufacturing.

Illustration of the Low Pressure Die Casting process, highlighting the controlled low-pressure environment and precise mold filling.

Explore medium pressure die casting and its advantages over sand casting, offering precision and efficiency in manufacturing.

Explore the differences between Alodine and anodizing for aluminum finishing, covering costs, durability, and applications.

Discover the precision and efficiency of high pressure die casting for manufacturing metal parts.

Squeeze casting merges casting and forging for high-quality metal parts with enhanced strength, precision, and cost-effectiveness.

Prevent hot cracking in die casting with insights into causes, effects, and solutions for better casting quality.

Overview of die casting inclusions, their effects, and practical controls in melt handling, tooling, and process to reduce scrap and improve part reliability.