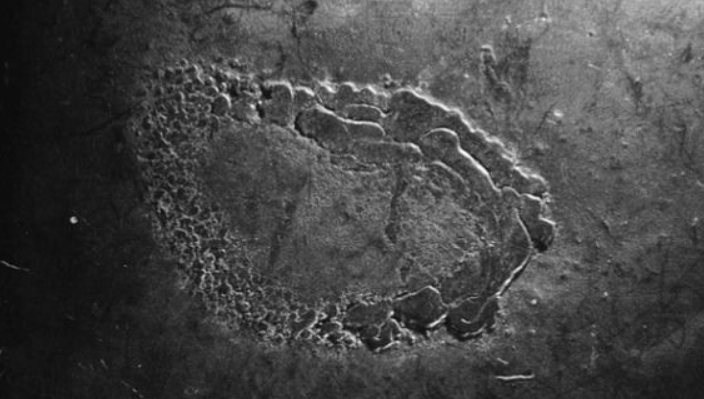

Eliminating Blister Defects in Die Casting

A detailed guide on preventing blister defects in die casting, highlighting the importance of proper venting, moisture management, and controlled heating in producing high-quality parts.

A detailed guide on preventing blister defects in die casting, highlighting the importance of proper venting, moisture management, and controlled heating in producing high-quality parts.

A definitive guide to preventing sink marks in die casting, highlighting the importance of uniform design, effective cooling systems, and precise process parameters for high-quality outcomes.

A guide to identifying and preventing leaks in die casting, emphasizing the importance of part design, quality control measures, and the optimization of the runner and sprue system.

Sprue vs runner in die casting: locations, roles, key differences, and design tips to reduce defects and improve yield.

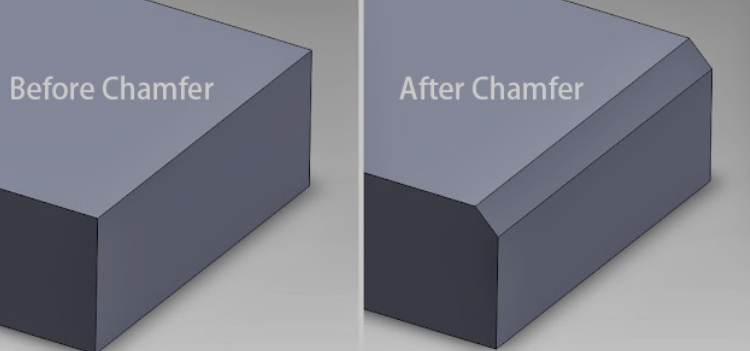

A practical guide to choosing chamfers vs fillets on aluminum die-cast and CNC parts—strength, assembly, cost, finish, and callouts.

Dive into the world of metal coatings with a detailed comparison between chromate and chrome coatings, covering their applications, benefits, and selection criteria for optimal metal protection and aesthetics.

Decide whether pad printing or screen printing fits your project by assessing your die-cast parts’ design complexity, surface, volume, and budget considerations.

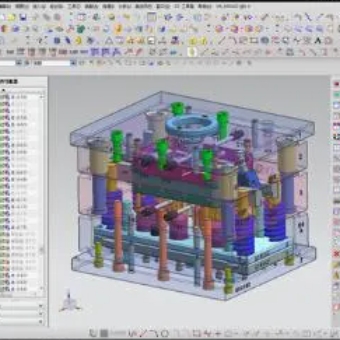

This guide covers everything about die casting gates and overflows, focusing on design optimization for improved part quality, reduced defects, and increased production efficiency.

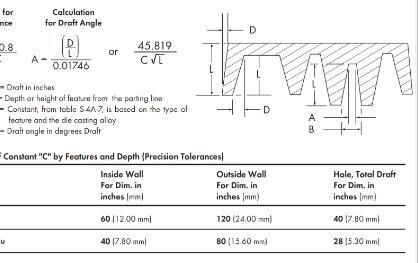

Practical draft-angle ranges, what changes them, finish add-ons, and our QC to keep ejection clean and surfaces consistent.