In the realm of metalworking and manufacturing, two prominent materials often compared are cast aluminum and wrought iron.

Both have unique properties and applications that make them suitable for various uses. Here, we provide an in-depth analysis of these materials to help you make an informed decision.

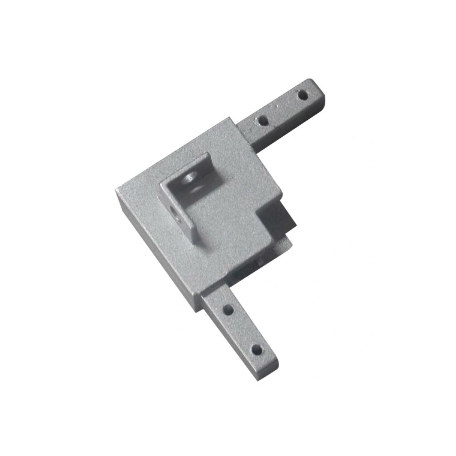

Understanding Cast Aluminum

Properties and Benefits

Cast aluminum is created by pouring molten aluminum into a mold, allowing it to solidify into the desired shape.

This process gives it several advantageous properties:

- Lightweight: Aluminum is significantly lighter than many other metals, making it ideal for applications where weight reduction is crucial.

- Corrosion Resistance: Naturally resistant to corrosion, aluminum is excellent for outdoor and marine environments.

- Strength: Although not as strong as wrought iron, cast aluminum provides sufficient strength for many structural applications.

- Malleability: It can be easily cast into complex shapes and intricate designs.

- Thermal Conductivity: Aluminum has high thermal conductivity, making it suitable for heat exchangers and radiators.

Common Applications

Cast aluminum is widely used in various industries due to its versatility:

| Automotive | Aerospace | Construction | Consumer Goods |

| -Engine components -Wheels -Structural parts. | -Aircraft frames -Components. | -Window frames -Roofing -Architectural features. | -Cookware -Furniture -Decorative items. |

Exploring Wrought Iron

Properties and Benefits

Wrought iron is a form of iron with a very low carbon content, making it tough, malleable, and corrosion-resistant.

Its properties include:

- Durability: Wrought iron is incredibly durable and can withstand significant stress and strain.

- Malleability: It can be easily worked into various shapes without breaking, ideal for decorative elements.

- Corrosion Resistance: With proper treatment, wrought iron resists rusting and corrosion.

- Aesthetic Appeal: Often used in ornamental designs, wrought iron has a timeless and classic look.

Common Applications

The durability and aesthetic qualities of wrought iron make it suitable for:

| Fencing and Gates | Furniture | Railings and Balustrades | Architectural Features |

| -Strong and secure -Providing both functionality -Decorative appeal. | -Outdoor -Indoor pieces | -Offering safety -Decorative elements | -Historical restorations -Custom design elements. |

Comparing Cast Aluminum and Wrought Iron

Strength and Durability

- Cast Aluminum: While strong, it does not match the durability of wrought iron. It is less prone to corrosion without needing extensive treatments.

- Wrought Iron: Extremely durable and capable of withstanding more physical stress. It requires maintenance to prevent rusting.

Weight

- Cast Aluminum: Much lighter, making it easier to handle and reducing overall weight in applications like automotive and aerospace.

- Wrought Iron: Heavier, which can be a disadvantage in applications where weight is a critical factor.

Aesthetic and Design Flexibility

- Cast Aluminum: Can be cast into complex shapes and designs, offering significant flexibility in manufacturing.

- Wrought Iron: Offers unmatched decorative appeal with its ability to be worked into intricate designs.

Cost

- Cast Aluminum: Generally more cost-effective due to lower material and production costs.

- Wrought Iron: More expensive due to the labor-intensive manufacturing process and the cost of iron.

Choosing the Right Material for Your Needs

When deciding between cast aluminum and wrought iron, consider the specific requirements of your application:

- For lightweight and corrosion-resistant needs, cast aluminum is often the better choice.

- For applications requiring high durability and a classic aesthetic, wrought iron is superior.

Conclusion

Both cast aluminum and wrought iron have their distinct advantages and are suited to different applications.

Whether you prioritize weight, strength, durability, or aesthetic appeal, choosing the right material will ensure optimal performance and longevity in your projects.