A die casting machine is the backbone of modern metal manufacturing. From automotive housings to consumer electronics, these machines make it possible to produce high-volume metal parts with precision and consistency.

Buyers searching for die casting machines usually want to know:

- What types exist (hot chamber, cold chamber, gravity, low pressure)?

- How much does a machine cost?

- Which manufacturers are reliable, including in India?

- What HS/HSN codes are used for import/export?

- Should you buy new, used, or outsource to a manufacturer?

This guide covers it all.

What Is a Die Casting Machine? (Meaning & Process)

A die casting machine injects molten non-ferrous metal into a steel mold cavity under pressure. Once cooled, the mold opens, and the part is ejected.

The die casting machine process works in five main steps:

- Melting

- Non-ferrous alloys like aluminum, zinc, or magnesium are melted.

- In a hot chamber die casting machine, the metal is melted inside the machine.

- In a cold chamber die casting machine, the metal is ladled from a separate furnace.

- Injection

- A hydraulic system forces molten metal into the closed die cavity under high pressure.

- Pressure ensures the mold fills completely, even with thin-walled parts.

- Cooling and Solidification

- The molten metal cools within the mold.

- High pressure minimizes porosity, creating dense and strong parts.

- Ejection

- The mold opens, and ejector pins push out the finished part.

- Excess metal is trimmed away.

- Repetition

- The cycle repeats rapidly.

- A modern machine can produce thousands to millions of parts per year.

👉 This makes die casting ideal for high-volume production where consistency matters.

Types of Die Casting Machines

Different types of die casting machines exist, each suited for specific materials:

| Machine Type | Suitable Materials | Features | Common Applications |

|---|---|---|---|

| Hot Chamber Die Casting Machine | Zinc, magnesium | Integrated furnace, fast cycle times | Electrical fittings, small zinc parts |

| Cold Chamber Die Casting Machine | Aluminum, magnesium, brass | External furnace, handles high-melting metals | Automotive housings, structural parts |

| High Pressure Die Casting Machine (HPDC) | Aluminum alloys | Very high injection pressure, thin-wall parts | Auto body, EV battery housings |

| Low Pressure Die Casting Machine | Aluminum | Uses gas pressure, controlled solidification | Wheels, thicker aluminum castings |

| Gravity Die Casting Machine | Aluminum, copper | Relies on gravity, no injection pressure | Medium-volume thick-wall parts |

👉 Example: A zinc die casting machine (hot chamber) is ideal for small, precise parts, while a cold chamber aluminum die casting machine handles large automotive housings.

Die Casting Machine Price Guide (180–2000T)

The cost of a die casting machine varies by tonnage. Machines range from small 180T units for electronics to massive 2000T machines for EV structural parts.

| Tonnage (Clamping Force) | Example Parts | Price Range (USD) |

|---|---|---|

| 180–300T | LED housings, small zinc/magnesium parts | $60,000 – $120,000 |

| 400–600T | Small/medium aluminum housings, auto covers | $120,000 – $220,000 |

| 800–1000T | Transmission cases, structural components | $200,000 – $400,000 |

| 1200–1600T | EV battery housings, engine blocks | $400,000 – $700,000 |

| 1800–2000T+ | Large chassis parts, aerospace housings | $700,000+ |

👉 Buyer insight: Bigger isn’t always better. Match tonnage to the projected area and wall thickness of your parts, not just their weight.

Price Factors Explained

Beyond tonnage, buyers should understand these cost drivers:

- Clamping Force

- The higher the force, the larger the parts you can make.

- Too low → molten metal leaks out (flashing).

- Too high → wasted energy and unnecessary cost.

- Automation Level

- Basic machines: manual ladling and part removal.

- Advanced machines: robots, vacuum casting, sensors.

- Automation adds cost but reduces labor and improves consistency in mass production.

- Machine Brand

- Premium brands (e.g., Bühler, Toshiba) → 15–20 years lifespan, stable precision.

- Local brands → lower upfront price, but more frequent downtime.

- Location

- Prices vary:

- Europe/Japan = higher.

- Die casting machine price in India = often 10–20% lower due to local sourcing.

- Logistics, customs, and local service networks must be factored in.

- Prices vary:

- Maintenance & After-Sales

- Machines need spare parts (tie-bars, pumps, controllers).

- No local support = long downtime.

- Always check if service centers and parts stock exist in your region.

👉 Total cost of ownership = Purchase Price + Operating Costs + Downtime Risk.

Leading Die Casting Machine Manufacturers

The global top brands supply machines for aluminum, zinc, magnesium, and copper alloys:

- Bühler (Switzerland) – Premium cold chamber, strong automation.

- Toshiba (Japan) – Reliable, long-lasting machines.

- Frech (Germany) – Hot chamber leader for zinc and magnesium.

- Idra (Italy) – Large cold chamber machines (2000T+).

- LK Machinery (China) – Full range, competitive cost.

- Yizumi (China) – Rapid growth, good after-sales in Asia.

- Kurtz Ersa (Germany) – Specializes in low pressure and gravity casting.

- UBE (Japan) – Large cold chamber machines for structural auto parts.

- Albertini (Italy) – Mid- to high-end European brand.

- Sodic (Japan) – Precision hot chamber machines for magnesium.

👉 These brands are not limited to aluminum—they build machines for all major die casting alloys.

HS Codes & Compliance

Correct customs classification is critical when importing or exporting.

HS Code Breakdown for Die Casting Machines

- Section XVI: Machinery and Mechanical Appliances

- Chapter 84: Boilers, machinery, and mechanical appliances

- Heading 8454: Converters, ladles, ingot moulds, casting machines

- Subheading 8454.30: Casting machines (including die-casting, continuous, centrifugal)

- Subheading 8454.30.10: Specific to die-casting machines

- Subheading 8454.30.90: Other casting machines

👉 Important Note: Always confirm the die casting machine HS code / HSN code with your country’s customs authority, as updates or variations may apply. Wrong codes can cause shipment delays and unexpected tariffs.

Key Specifications Buyers Must Check

| Factor | What It Means | Why It Matters | Buyer’s Takeaway |

|---|---|---|---|

| Clamping Force (Tonnage) | Pressure keeping the mold shut during injection | Too low → leakage; too high → wasted energy | Small parts need ~300T, large EV housings need 1600T+ |

| Casting Area | Mold surface facing molten metal | Larger projection = higher force required | Don’t judge only by weight; shape matters more |

| Machine Brand | Engineering quality & global presence | Affects uptime, quality, and spare parts supply | Bühler = premium reliability; LK = broad, economical |

| Automation Options | Robots, vacuum, sensors | Improves consistency, reduces labor, raises upfront cost | High-volume = worth it; low-volume = optional |

| After-Sales Support | Service and spare part availability | Poor support = weeks of downtime | Always check for local dealer/service coverage |

Advanced FAQ — Die Casting Machines (Practical, Data-Backed)

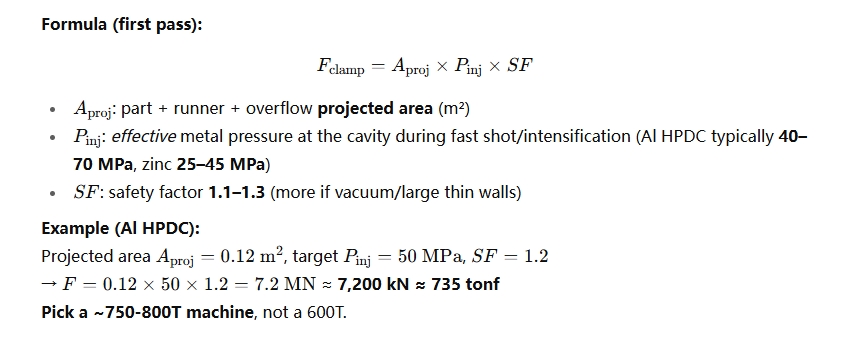

1) How do I estimate the required clamping force for a new part?

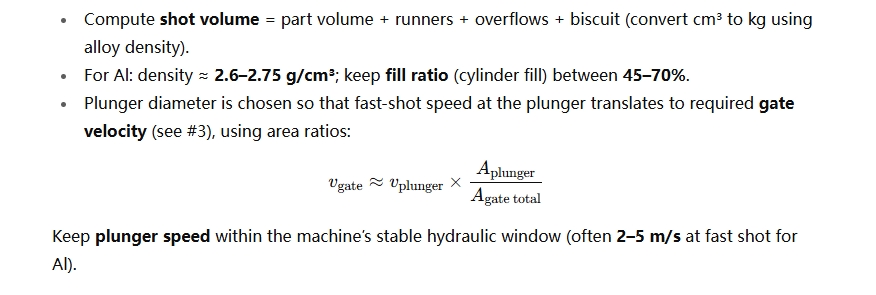

2) How do I sanity-check shot volume and plunger diameter?

3) What gate velocity and fill time should I target for aluminum HPDC?

- Gate velocity (Al HPDC): typically 30–60 m/s (thin walls near the high end).

- Cavity fill time: 30–120 ms depending on wall thickness; thin, long flow paths → shorter fill time.

- Too slow: cold shuts/misruns. Too fast: erosion/soldering.

- Validate with simulation and adjust gate thickness (≈ 0.8–1.2× wall) and runner balance.

4) What vacuum level is “good enough” for structural parts?

- For heat-treatable/structural Al HPDC, vacuum at the die before metal arrival should reach ≤ 50–80 mbar; aggressive specs target ≤ 30 mbar.

- Check leak rate (die tightness) and pump capacity vs die cavity volume.

- With good vacuum + proper overflows, StD porosity and weldability improve markedly.

5) How do I break down cycle time and spot bottlenecks?

Typical Al HPDC cycle (illustrative):

- Die close & slow shot: 1–2 s

- Fast shot & fill: 0.03–0.12 s

- Intensification & solidification dwell: 10–40 s (thicker parts → longer)

- Die open & ejection: 1–2 s

- Spray/lube & cool: 3–8 s

Total: 15–55 s per shot (widely varies). Focus on spray time and solidification dwell for gains; stabilize die thermal balance (next Q).

6) What die temperature window should I run for aluminum?

- Preheat dies to 180–220 °C, run control typically 180–250 °C, keep ±10 °C balance across cores/cavities.

- Hot spots → soldering/erosion; cold spots → cold shuts. Use targeted baffles, bubblers, and pulsed water circuits; avoid over-spray that chills steel unevenly.

7) What’s a good overflow & venting strategy (with vacuum)?

- Provide generous overflows at flow ends and weld lines; think of them as “air/oxide traps” not just metal reservoirs.

- Keep vacuum vent land short and controlled (typical gaps for Al are in the 0.02–0.05 mm range with hardened inserts; confirm with your die supplier).

- Place gate→part→overflow in one continuous flow vector to avoid air entrapment U-turns.

8) What intensification pressure should I specify?

- Al HPDC intensification typically 50–80 MPa at the biscuit (effective pressure at cavity is lower).

- Use higher end for thin walls/long flow and when aiming for heat treatment or pressure-tight parts.

9) How long will my die last?

- Aluminum: 80k–250k shots is a common band (steel grade, coatings, thermal control, part geometry, and lube discipline matter).

- Zinc: often >500k shots, even ~1M for favorable designs.

- Watch for heat-checking, soldering, and erosive wear at gates/cores; schedule refurb before cracks propagate.

10) What’s a realistic scrap rate and how to drive it down?

- Ramp-up: 10–20% not unusual; stabilized production: <5–8% is a good target; best-in-class lines can hit ~2–3% on steady parts.

- Attack top defects with DOE on shot speed switchover, intensification delay, die temp zoning, and lube recipes; enforce first-off approvals every coil change/shift.

11) How do energy use and cost per kg typically look?

- Modern Al HPDC cells (with thermal management, servo pumps where equipped): ~0.8–1.2 kWh/kg cast metal (process only; excludes melting if done externally).

- Total piece cost is dominated by cycle time, scrap, tool amortization, and secondary ops (trim/machine/coat). Shaving 3–5 s off cycle or 3–5% scrap often beats negotiating machine price by a few percent.

12) Hydraulic vs servo-hydraulic vs hybrid—does it matter?

- Conventional hydraulic: lower capex, mature, robust.

- Servo-hydraulic/hybrid: better energy efficiency, finer speed/pressure control, quieter; premium upfront, OPEX can be lower for high-utilization cells.

- If annual shots are high (automotive), servo often pays back in 12–36 months via energy and stability gains.

13) What should I check when buying a used machine?

- Platen parallelism and tie-bar stretch within maker’s spec; inspect bushings and toggle pins.

- Verify accumulators, pumps, valve blocks, and controller I/O; run a dry cycle time test and shot repeatability check (pressure/speed traces).

- Confirm availability of spare parts and local service; review maintenance logs and actual shot counter (not just HMI value).

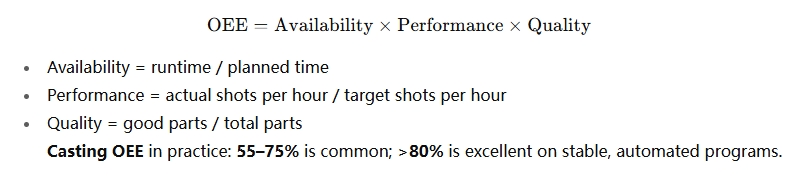

14) How do I quantify line performance (OEE)?

15) Do “India vs EU/JP” machines only differ on price?

- Often 10–20% capex delta (sometimes more).

- Consider through-life: closed-loop controls, sensor fidelity, valve response, data logging, and service coverage drive real-world uptime and consistency.

- For complex Al structural parts (vacuum + tight porosity specs), higher-end control/diagnostics can be decisive.

16) What HS codes actually apply (import/export)?

- Heading 8454, Subheading 8454.30 (casting machines)

- 8454.30.10: Die-casting machines

- 8454.30.90: Other casting machines

Always confirm with local customs (tariff schedules update, and descriptions can vary by jurisdiction).

Why Work With Us Instead of Buying a Machine?

While this guide explains everything about die casting machines, not every buyer should own one.

- New machines cost $500,000+.

- Maintenance, operators, and downtime add more expense.

- Many companies instead choose to partner with die casting machine manufacturers to outsource production.

At our factory:

- We operate 180T–2000T cold chamber high pressure die casting machines.

- We serve automotive, electronics, and industrial clients.

- We provide full quality control: CMM, spectrometer, X-ray.

👉 Need aluminum die casting expertise? Read our Aluminum Die Casting Machine Buyer’s Guide.

📩 Send us your RFQ today to get reliable parts without investing in expensive equipment.

Final Thoughts

The die casting machine is essential for producing complex metal parts. Buyers must evaluate machine type (hot vs cold vs gravity vs low pressure), tonnage range (180–2000T), brand, price factors, and HS codes before purchase.

But for most, outsourcing to an experienced die casting machine manufacturer is the smarter choice—saving capital while ensuring top-quality parts.