Importance of Electric Vehicle Control Housing

Electric vehicle (EV) control housing is a critical component in the overall structure of an electric vehicle.

Its primary function is to protect the internal electronic components, ensuring the EV operates normally under various environmental conditions.

Key Design Elements of EV Control Housing

Material Selection

Materials must possess high thermal conductivity, excellent electrical insulation properties, and strong resistance to environmental factors such as moisture, dust, and chemicals.

Commonly used materials include aluminum alloys, magnesium alloys, and advanced plastics.

Structural Design

The structural design of the control housing must ensure adequate protection for the internal components while maintaining lightweight characteristics to not add unnecessary weight to the vehicle.

This involves precise engineering to balance strength and weight.

Prototype Development

Once the design phase is complete, a prototype of the control housing is developed. This prototype is used to assess the design’s practicality and make necessary adjustments.

During this stage, engineers focus on verifying the dimensions, material properties, and overall functionality.

Testing and Validation

Before mass production, the prototype undergoes rigorous testing and validation processes. These tests include thermal performance tests, mechanical stress tests, and environmental resilience tests.

The objective is to ensure the control housing can withstand real-world conditions and perform reliably over time.

Thermal Performance Tests

These tests evaluate the housing’s ability to dissipate heat generated by the electronic components. Efficient thermal management is vital to prevent overheating and ensure optimal performance.

Mechanical Stress Tests

Mechanical stress tests assess the housing’s durability and ability to protect internal components from shocks, vibrations, and other physical impacts that may occur during vehicle operation.

Environmental Resilience Tests

Environmental tests expose the housing to extreme conditions such as high humidity, salt spray, and temperature fluctuations to ensure its longevity and reliability in various climates and environments.

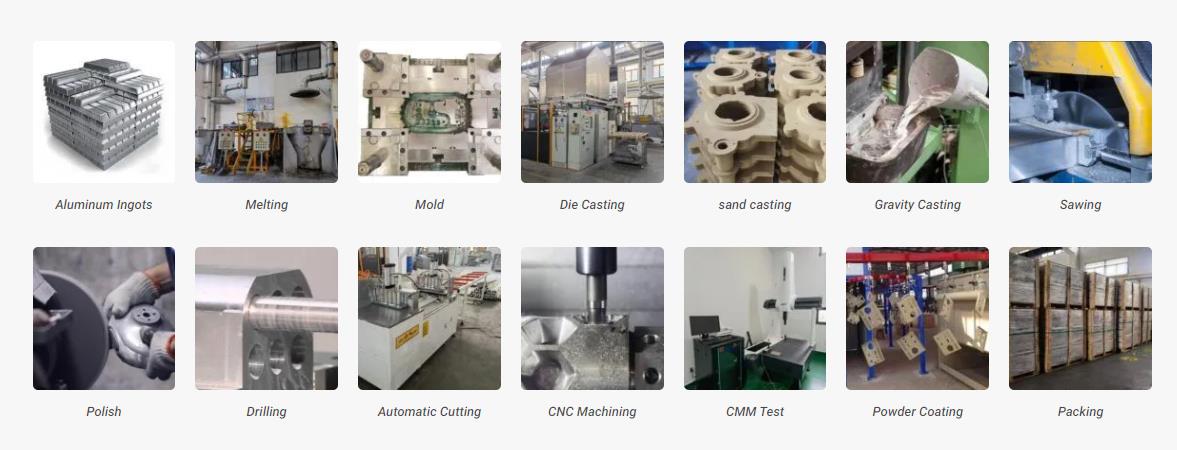

Production Process

After successful testing and validation, the production process begins. This involves precision manufacturing techniques to ensure each unit meets the stringent design specifications. The production phase includes casting, machining, assembling, and finishing processes.

Casting

Casting is the initial step in manufacturing the control housing, where the chosen material is shaped into the desired form. High precision molds are used to achieve accurate dimensions and intricate designs.

Machining

Post-casting, the housing undergoes machining to refine its shape and ensure all surfaces are smooth and meet the specified tolerances. This step is crucial for fitting the internal electronic components perfectly.

Assembling

The assembly process involves integrating various parts of the control housing and fitting it with necessary components like seals and gaskets. This step ensures the housing is fully functional and ready for final finishing.

Finishing

The finishing process includes surface treatments such as coating and painting to enhance the housing’s appearance and provide additional protection against environmental factors.

Quality Control

Quality control is an integral part of the production process. Each unit undergoes thorough inspections to ensure it meets all design and performance criteria. This includes visual inspections, dimensional checks, and functional tests.

Contact us today to discuss your project needs and receive a quote, you can trust us to deliver exceptional castings that meet your requirements.