The Importance of Street Lighting

Street lighting plays a crucial role in ensuring safety and visibility for both pedestrians and vehicles. It enhances the aesthetic appeal of streets and public spaces, contributing to the overall quality of life.

When it comes to street lighting components, aluminum die casting has become the go-to choice for many municipalities and cities.

This is due to the material’s strength, corrosion resistance, lightweight nature, and ability to be molded into intricate shapes.

Let’s explore how aluminum die casting is used in street lighting components like poles, fixtures, and supports, and why it’s increasingly becoming the preferred choice in street lighting infrastructure.

Types of Roads and Their Impact on Street Lighting Requirements

Different road types demand different specifications for street lighting.

Understanding these needs is essential for designing lighting systems that not only provide adequate illumination but also meet the safety, aesthetic, and environmental demands of specific areas.

- Highways: Highways require taller street poles to provide broader visibility over long stretches of road. These poles are generally built to withstand harsher weather conditions and stronger winds, particularly in coastal or storm-prone areas.

- Urban Roads: Urban streets prioritize aesthetics, energy efficiency, and integration with the surrounding urban environment. Street lighting fixtures are designed to blend with architectural features and contribute to the overall urban landscape.

- Rural Roads: Rural areas focus on cost-effective, durable street lighting solutions that are easy to maintain. Lighting poles used in rural areas are typically shorter and less ornate, focusing on functionality rather than design.

Classification of Street Lighting Poles

Street lighting poles come in a variety of designs and specifications, which depend largely on their function, location, and environmental conditions.

These poles not only serve the purpose of holding lights but also need to be strong enough to withstand various elements, including wind, rain, saltwater, and extreme temperatures.

- Design Variations: Street lighting poles come in many designs. Some are simple, straight poles, while others have artistic elements designed to match the surrounding environment. For urban areas, poles often have decorative elements that complement the architecture.

- Materials Used: Aluminum alloys, such as A356 or A380, are often used for street lighting poles. These materials are strong, lightweight, and corrosion-resistant, which is essential for ensuring the longevity of the poles, especially in harsh weather conditions. The combination of aluminum’s lightweight nature and its strength makes it a preferred material in designing poles that must support heavy fixtures while remaining structurally sound.

- Special Requirements:

- Coastal Areas: In coastal areas, the air contains salt, which can cause corrosion. Aluminum’s natural corrosion resistance makes it an ideal material for poles in such environments.

- Storm-Prone Areas: Areas prone to hurricanes or heavy storms need poles designed to withstand high winds. Aluminum poles are reinforced with thicker walls and ribs to improve their resistance to wind forces.

- Cold Regions: In colder climates, aluminum alloys that perform well at low temperatures are chosen. These materials ensure the poles do not become brittle and can withstand freezing conditions.

Street Lighting Pole Height and Distance Between Poles

The height of street lighting poles and the distance between them is crucial for ensuring proper illumination and safety.

There are standard guidelines that municipalities and contractors follow to design effective lighting systems for different types of roads.

- Pole Heights: Typically, the height of street lighting poles varies based on the type of road:

- Urban Streets: Poles usually range from 8 to 12 meters in height, providing enough light coverage for sidewalks and small traffic areas.

- Highways: For highways, poles are generally much taller, ranging from 12 to 15 meters, to ensure long-distance visibility.

- Rural Roads: These poles are usually on the shorter end, around 6 to 8 meters, since they don’t require the same level of illumination as highways or urban streets.

- Distance Between Poles: The distance between poles depends on several factors, including pole height, road type, and the desired lighting intensity. Generally, for urban streets, poles are placed 25 to 30 meters apart, while for highways, they can be spaced as far as 50 meters apart. These distances are designed to ensure that light covers the road evenly and reduces dark spots.

Industry Standards for Street Lighting

Countries around the world have established their own standards for street lighting.

These standards dictate the necessary pole height, material quality, and lighting requirements for different environments.

For instance, in the U.S., the Illuminating Engineering Society (IES) provides guidelines for street lighting design, while the British Standard BS 5489 governs the lighting of streets in the UK.

Similarly, in Europe, the EN 13201 standard specifies street lighting requirements for both urban and rural roads.

Aluminum Die Casting for Street Lighting: A Growing Trend

The use of aluminum die casting in street lighting is growing due to the increasing demand for lightweight, durable, and corrosion-resistant materials.

Aluminum poles and fixtures are not only stronger but also require less maintenance, making them cost-effective in the long run.

As municipalities continue to seek ways to improve energy efficiency and reduce long-term costs, aluminum die casting for street lighting components is becoming the standard.

Conclusion

Aluminum die casting is a key component in the design and production of street lighting systems.

From the poles to the fixtures, aluminum provides the strength, durability, and aesthetic appeal needed for effective lighting solutions.

As urbanization and infrastructure development continue, aluminum will play an increasingly important role in creating sustainable and safe environments for communities worldwide.

Searching for High-Quality for Cast Aluminum Parts?

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Zhejiang Yongzhu Casting Technology Co., Ltd.

Location: Zhejiang, Shaoxing

Company type: Manufacturing

Year Founded: 2004

Main Products: Aluminium die casting, Mold Making, Die Casting, Sand Casting, Gravity Casting

Leading Chinese producer Yongzhu Casting is formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

With 20 years of experience in the industry, we are a specialized manufacturer in Aluminum casting and Machining.

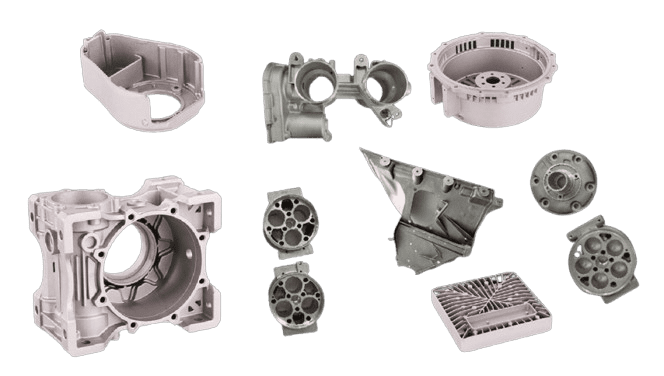

Our products are widely used in various applications such as Automotive, Energy, Lighting, Medical, Home Furnishings, Machinery & Equipment etc. Below is one of our products.

It’s worth mentioning that the evolution of rapid logistics has transformed how industries approach purchasing. Aluminum casting orders can now be sourced from overseas suppliers efficiently.

For instance, working with YONGZHU CASTING, you can inquire, order, and even find better value than your local options—all while maintaining assured quality.

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings. Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis and 5-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency. We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart. We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.