Gas porosity is a significant issue in aluminum die casting, impacting the quality and integrity of cast products.

This guide delves into the causes, types, detection methods, and mitigation strategies for gas porosity in aluminum die casting.

Causes of Gas Porosity in Aluminum Die Casting

| Factor | Description | Solution |

|---|---|---|

| Gas Solubility | Aluminum has a high solubility for hydrogen, making it prone to gas porosity. During melting, hydrogen can dissolve into the molten aluminum, leading to gas entrapment during solidification. | Use effective degassing techniques to reduce hydrogen content in the molten aluminum. |

| Inadequate Degassing | Insufficient degassing processes can leave residual hydrogen in the molten aluminum. | Implement rotary or vacuum degassing methods to minimize gas content. |

| High Pouring Temperature | Excessive pouring temperatures increase the solubility of gases in aluminum. | Maintain optimal pouring temperatures to control gas absorption and reduce porosity. |

| Poor Mold Venting | Inadequate venting in the mold design can trap gases within the casting. | Ensure proper mold design with sufficient venting channels to allow gases to escape. |

Types of Gas Porosity

| Defect | Description | Impact |

|---|---|---|

| Blowholes | Large, spherical voids near the surface caused by trapped gases. | Significantly weaken the structure of the cast product. |

| Pinholes | Small, numerous pores caused by dissolved hydrogen. | Distributed throughout the casting, reducing overall integrity. |

| Wormholes | Elongated, irregular voids formed by incomplete degassing. | Can extend through significant portions of the casting, compromising its integrity. |

Detection Methods

| Method | Description | Capability |

|---|---|---|

| Visual Inspection | Examination of the casting surface for visible defects. | Detects surface blowholes and some subsurface defects. |

| Radiographic Testing (RT) | Uses X-rays or gamma rays to inspect internal structures. | Reveals internal porosity and other defects. |

| Ultrasonic Testing (UT) | Uses high-frequency sound waves to detect subsurface defects. | Identifies gas porosity within the casting. |

| Computed Tomography (CT) Scanning | Provides detailed 3D images of internal structures. | Allows precise identification and analysis of porosity. |

Mitigation Strategies

| Strategy | Description |

|---|---|

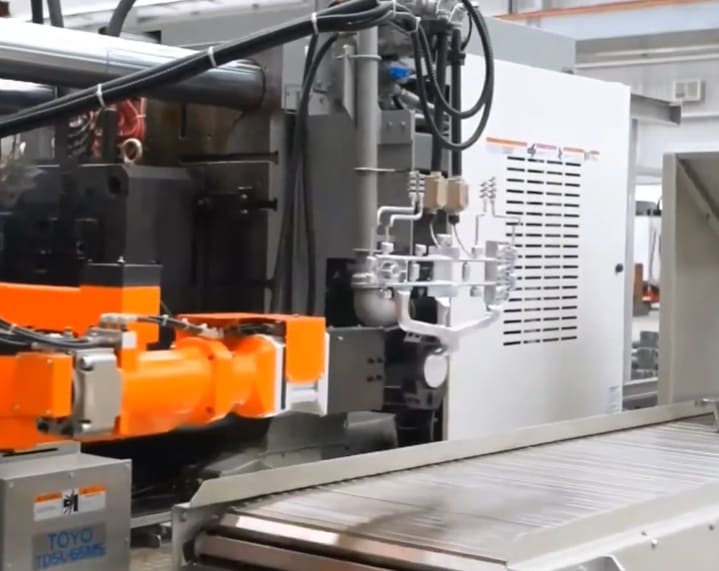

| Controlling Melting and Pouring Processes | Regulating temperature and atmosphere during melting and pouring reduces gas absorption in molten aluminum. |

| Enhanced Degassing Techniques | Utilizing advanced methods like rotary degassing or vacuum degassing effectively removes dissolved gases. |

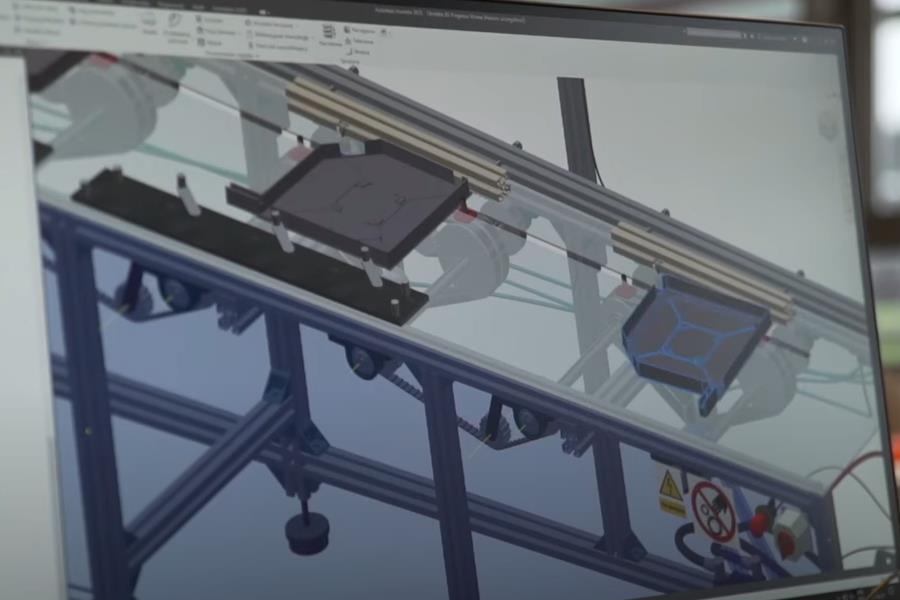

| Improved Mold Design | Designing molds with adequate venting and gas escape channels to prevent gas entrapment. |

| Use of Gas-Absorbing Materials | Adding materials such as fluxes or degassing tablets helps decrease gas content in molten aluminum. |

| Real-Time Monitoring | Implementing real-time systems to monitor and control gas levels ensures better quality control and minimizes porosity. |

Gas porosity is a critical challenge in aluminum die casting. With a thorough understanding of its causes and effective mitigation strategies, its impact can be minimized.

By optimizing melting and pouring processes, enhancing degassing techniques, improving mold design, and utilizing advanced inspection methods, manufacturers can produce high-quality aluminum castings with reduced porosity.

For further discussion on these topics, please feel free to contact us.