In aluminum die casting, the internal grain structure plays a decisive role in determining the final mechanical strength, surface quality, and resistance to cracking. Grain refinement—the process of reducing crystal size during solidification—has become an essential step in achieving high-performance castings for demanding applications such as lighting, automotive, and electronics.

At Yongzhu Casting, we incorporate multiple grain refinement control measures during both the melting and solidification stages. This ensures consistent grain structure, fewer casting defects, and improved machinability across every die-cast component.

What Is Grain Refinement in Aluminum Casting

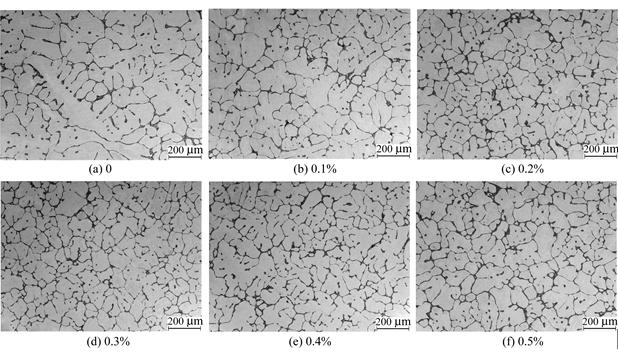

Grain refinement is the process of forming fine, equiaxed grains instead of large columnar crystals during the solidification of molten aluminum.

When aluminum cools, crystals naturally grow outward from the mold wall. If cooling is uneven or nucleation is limited, coarse dendritic structures appear, leading to weaker, more brittle castings.

Refining the grain structure introduces more nucleation sites, promoting uniform solidification and reducing stress concentration points—two key contributors to defects like hot cracking and porosity.

How Grain Refinement Works During Solidification

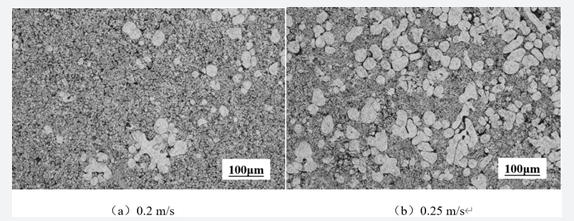

During aluminum die casting, molten metal begins solidifying rapidly under pressure. Grain refinement occurs when multiple nucleation sites form throughout the melt, producing smaller and more uniform grains.

Fine grains result from controlled solidification: rapid cooling increases the number of nuclei, while reduced temperature gradients minimize columnar crystal growth. This promotes an equiaxed structure that enhances strength, ductility, and fatigue resistance.

In practical die casting, factors such as melt cleanliness, cooling rate, and temperature uniformity in the mold cavity all determine how effectively refinement can occur. By controlling these variables, manufacturers can suppress defects like hot cracking and porosity while achieving a dense microstructure.

Understanding the solidification mechanism helps engineers choose the right refining technique for specific aluminum alloys.

Techniques Used to Achieve Grain Refinement in Aluminum Die Casting

Several engineering techniques are applied in aluminum die casting to ensure effective grain refinement:

• Chemical Inoculation (Al–Ti–B and Al–Ti–C Master Alloys) – The most widely used approach. Fine TiB₂ and TiC particles act as nucleation sites, promoting uniform crystal formation and minimizing coarse dendritic grains.

• Electromagnetic Stirring – Induces controlled convection in the molten aluminum, distributing alloying elements evenly and reducing segregation, which helps form finer equiaxed grains.

• Ultrasonic Vibration – Creates cavitation and acoustic streaming in the melt, breaking dendrite arms and dispersing them as new nuclei, resulting in a refined microstructure.

• Optimized Cooling and Mold Temperature Control – Rapid and uniform heat extraction increases solidification rate, improving grain uniformity and minimizing hot tearing risk.

By combining these techniques, die casters can refine grains effectively, improve metallurgical integrity, and produce aluminum components with higher mechanical reliability.

Effects of Grain Refinement on Casting Quality

Grain refinement does more than improve appearance—it transforms mechanical behavior. Below are the measurable improvements often observed:

| Property | Without Refinement | With Refinement |

|---|---|---|

| Average Grain Size | 100–150 µm | 20–50 µm |

| Ultimate Tensile Strength | 160–180 MPa | 200–230 MPa |

| Elongation | 1.5–2.0 % | 4–6 % |

| Surface Quality | Rough, visible dendrites | Smooth, uniform finish |

| Hot Cracking Susceptibility | High | Significantly reduced |

Refined grains improve feeding during solidification, minimize hot spots, and increase thermal fatigue life—especially critical for components with thin walls or complex geometry.

How Grain Refinement Prevents Common Casting Defects

- Reduced Hot Cracking

Fine grains improve the alloy’s ability to accommodate shrinkage strain, reducing internal tensile stress during solidification. - Less Porosity and Segregation

Homogeneous nucleation ensures uniform solute distribution, minimizing micro-shrinkage and gas pockets. - Improved Machinability

A refined microstructure provides consistent hardness and reduces tool wear during CNC machining. - Enhanced Surface Finish

Fine grains produce smoother die surfaces, crucial for anodized or decorative aluminum parts.

Yongzhu Casting’s Control Over Grain Structure

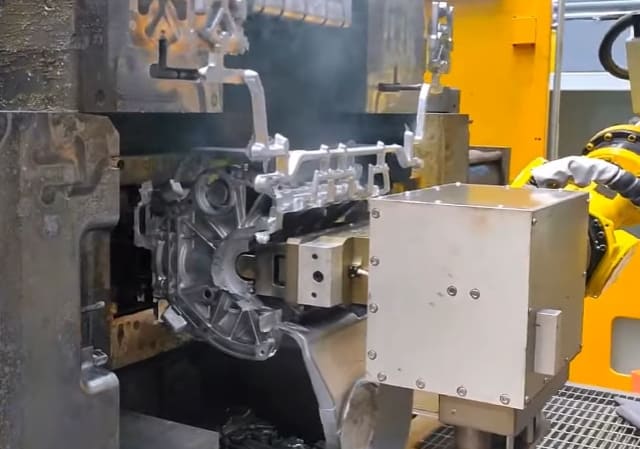

At Yongzhu Casting, our aluminum die-casting process integrates both equipment capability and metallurgical refinement:

- Die Casting Machines: 800–2000 tons closing force for stable high-speed injection

- Furnace Control: ±5 °C temperature stability ensures uniform melt condition

- ProCAST Simulation: Predicts solidification rate and grain size before tooling

- Alloy Refining: Continuous degassing and Al–Ti–B inoculation to control microstructure

- Post-Casting Inspection: Microstructure analysis to verify grain uniformity

This process control allows Yongzhu to deliver high-density aluminum parts with superior mechanical stability, ideal for lighting housings, motor enclosures, and automotive brackets.

Practical Benefits for Buyers

- Reduced Defect Rate: Up to 30 % lower incidence of hot tears or porosity.

- Improved Surface Aesthetics: Consistent finish suitable for anodizing or powder coating.

- Better Dimensional Stability: Fine grains minimize distortion under thermal cycling.

- Higher Mechanical Reliability: Stable microstructure enhances load-bearing performance.

- Consistent Quality Across Batches: Strict metallurgical control ensures repeatability.

Conclusion

Grain refinement is not merely a metallurgical adjustment—it is a strategic process control that determines how aluminum behaves under stress, machining, or finishing.

With refined grain structures, aluminum die castings achieve higher precision, greater reliability, and improved visual appeal.

Yongzhu Casting applies systematic refinement technologies—from melt inoculation to real-time solidification control—to ensure every part meets the stringent requirements of global lighting, automotive, and industrial OEMs.