Medium pressure die casting is a manufacturing process where molten metal fills a metal mold at moderate pressure, typically ranging from 3 to 100 MPa (megapascals).

This method strikes a balance between the high pressure of High-Pressure Die Casting (HPDC) and the low pressure of Low-Pressure Die Casting (LPDC).

It is favored for producing complex parts with high precision and quality finishing, offering cost-effectiveness and durability.

Process of Medium Pressure Die Casting

- Mold Designing: A mold, usually made of steel, is designed according to the required geometry, incorporating cavities, cores, and intricate details.

- Mold Melting: Metal alloys such as zinc, aluminum, or magnesium are melted in a furnace until they reach the desired temperature and consistency.

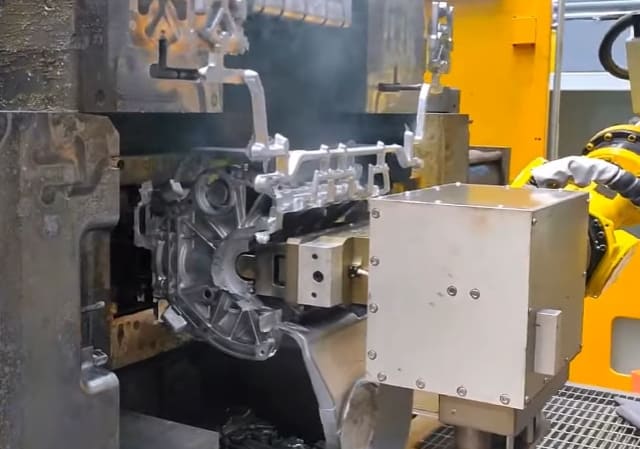

- Molten Metal Injection: The molten metal is injected into a holding furnace and then into the mold at moderate pressure to ensure desired properties.

- Cooling and Solidification: The filled mold is allowed to cool down, ensuring proper solidification to prevent defects in the casting product.

- Ejection of Casting: Once the metal has solidified, the part is carefully ejected from the mold, ensuring the shape is fully formed.

- Finishing: Trimming and finishing steps are applied to remove excess material and ensure the product meets design requirements.

- Quality Control: Inspection is conducted to ensure overall product quality, surface finishing, and structural integrity.

Difference Between Medium Pressure Die Casting and Sand Casting

The primary difference lies in the process complexity and material selection:

| Aspect | Medium Pressure Die Casting | Sand Casting |

|---|---|---|

| Process Complexity | Automated and precision-oriented. | Traditional and labor-intensive. |

| Material Selection | Primarily uses non-ferrous metals like zinc, aluminum, and magnesium for high precision. | Can utilize both ferrous and non-ferrous metals. |

Applications of Medium Pressure Die Casting

Medium pressure die casting finds extensive applications in various industries:

| Industry | Applications |

|---|---|

| Automotive | Engine components, transmission parts, complex automotive parts |

| Aerospace | Aircraft components including turbine blades, structural elements |

| Electronics | Electric devices, heat-resistant electronic connectors, complex electronic parts |

| Consumer Goods | Cookware, camera bodies, items requiring durability and precision |

| Medical Equipment | Surgical instruments, diagnostic machine components, biocompatible medical equipment |

Benefits of Medium Pressure Die Casting

- High Precision: Remarkable dimensional accuracy and repeatability.

- Improved Surface Finishing: Smooth surface options and reduced porosity.

- Design Flexibility: Lightweight designs with thin walls for specific engineering requirements.

- Cost-Effectiveness: Economical production with reduced waste and processing time.

Conclusion

Medium pressure die casting offers a balance of precision and efficiency, making it suitable for crafting complex product designs. .

With its eco-friendly and cost-effective nature, medium pressure die casting serves as a versatile solution in the casting industry.

Contact us today to discuss your project needs and receive a quote, you can trust us to deliver exceptional castings that meet your requirements.