Choosing the right dining table for your restaurant is more than just picking a stylish piece of furniture.

As an aluminum die-cast manufacturer, I know that the right table doesn’t just look good; it has to be durable, functional, and suit the space and purpose of your establishment.

Whether you’re outfitting a cozy family restaurant or a bustling corporate cafeteria, here are the essential factors you should consider.

What Are the Essential Features of a Restaurant Dining Table?

When selecting a dining table for your restaurant, the goal is to balance form and function. A good table should be sturdy, easy to maintain, and offer comfort to your guests.

- Types of Restaurants to Consider:

- Family Restaurants: These need tables that offer comfort and style but can also withstand everyday use. A family restaurant might prefer round or rectangular tables that can be rearranged easily to accommodate various party sizes.

- Fine Dining Restaurants: Elegance is key here. These establishments usually need high-end tables that complement a sophisticated atmosphere.

- Corporate Cafeterias: These require durable and simple tables. The focus is on functionality, so tables here are often designed for high throughput.

- Western Restaurants: For an upscale look, Western restaurants may prefer rectangular or square tables made from high-quality materials.

- Chinese Restaurants: Round tables are common in Chinese restaurants to encourage sharing dishes and creating a communal atmosphere.

How to Choose a Dining Table Based on the Restaurant’s Interior Style?

Your dining table should complement the overall theme of your restaurant’s interior design. Whether you’re going for modern, rustic, or industrial, the style of your table plays a key role in enhancing the dining experience.

- Popular Restaurant Interior Styles:

- Modern Minimalism: Clean lines, neutral colors (like white, grey, and black), and simple shapes are characteristic. This style complements tables with sleek, metal legs or glass tops.

- Rustic: Emphasizing natural materials like wood, this style is often warm and inviting. The tables are usually made of reclaimed wood or have distressed finishes.

- Industrial: Featuring exposed metal and wood, industrial style tables often have sturdy, bold frames. Aluminum or steel bases fit well with this style.

- Boho Chic: Colorful and eclectic, with a mix of textures. This style may incorporate wooden tables with metal legs or colorful painted designs.

- Traditional Classic: This style focuses on elegant, classic designs often using wood or glass. Dark wood or carved details are typical of tables in this style.

- Contemporary: Combining modern and traditional elements, contemporary style tables may feature a mix of materials, including metal, wood, and glass.

How to Determine the Right Size for a Restaurant Dining Table?

Choosing the right size for your dining table depends on the available space and the number of diners you typically serve. You don’t want your tables to take up too much space but you also want your customers to feel comfortable.

- Common Table Sizes:

- Two-Person Tables: Usually round or small rectangular tables, perfect for intimate dining or café settings.

- Four-Person Tables: Square or rectangular tables that provide ample space for a small group.

- Eight-Person Tables: Larger rectangular or round tables, commonly used in fine dining or for group settings.

- Expandable Tables: If your restaurant gets varying numbers of guests, consider tables that can expand to accommodate more diners. This is a popular choice for restaurants that host events or have varying traffic throughout the day.

What Materials Should You Choose for Restaurant Dining Tables?

The material you choose impacts both the look and the durability of the table. Different materials are suited for different types of restaurants.

- Materials to Consider:

- Wood: Classic and warm, perfect for family restaurants or homey cafés. However, wood may be prone to scratches and damage over time.

- Glass: Elegant and sophisticated, glass tables are often used in fine dining establishments. However, glass can be fragile and may not be the best option for high-traffic restaurants.

- Metal (Aluminum): Known for its durability and modern look, metal tables (especially those with aluminum die-cast components) are excellent for high-traffic restaurants. Aluminum is lightweight, resistant to rust, and easy to maintain.

- Stone: Durable and sophisticated, stone tables are typically used in upscale restaurants. They’re perfect for creating a high-end, timeless look.

- Plastic or Laminate: These materials are easy to clean and maintain, making them ideal for fast-casual restaurants or cafeterias. They are often affordable, but they might not offer the same aesthetic value as higher-end materials.

How to Choose the Right Design for Restaurant Dining Table Legs?

The legs of your dining table are not just functional but can also be a significant design element. Whether you’re aiming for industrial strength or elegant simplicity, the design of the table legs impacts the overall look of your restaurant.

- Types of Table Legs:

- Wooden Legs: Warm and traditional, these legs are often seen in family-style or rustic restaurants.

- Metal Legs (Aluminum, Steel, etc.): Industrial and sleek, metal legs offer durability and can be used in modern, industrial, or even contemporary settings. Aluminum die-cast legs, for example, provide strength while remaining lightweight.

- Pedestal Legs: These are great for round tables and provide more space underneath the table, making them ideal for smaller spaces.

- Trestle Legs: A popular choice for large, rectangular tables, these legs are sturdy and can support heavier tabletops.

- Hairpin Legs: These thin, curved metal legs have a vintage feel, often used in industrial or mid-century modern designs.

At the end of the day, the right material and design for your dining table will depend on your restaurant’s specific needs. As a manufacturer of aluminum die-cast components, we provide durable and stylish table legs, perfect for any restaurant looking to combine function with aesthetics.

Aluminum legs are not only lightweight and strong but also resistant to corrosion, making them ideal for both indoor and outdoor restaurant settings.

If you are a restaurant furniture manufacturer, aluminum die-cast components from our factory are an excellent option for creating high-quality, long-lasting dining tables.

Searching for High-Quality for Cast Aluminum Parts?

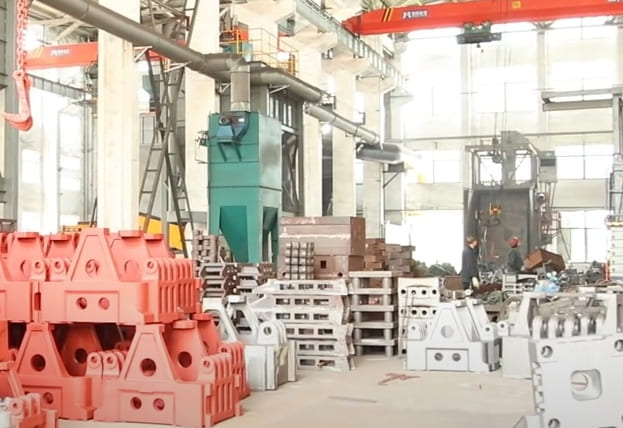

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Zhejiang Yongzhu Casting Technology Co., Ltd.

Location: Zhejiang, China

Company type: Manufacturers, Producers, Wholesalers

Year Founded: 2004

Main Products: Aluminium die casting, Mold Making, Die Casting, Sand Casting, Gravity Casting

Leading Chinese producer Yongzhu Casting is formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

With 20 years of experience in the industry, we are a specialized manufacturer in Aluminum casting and Machining.

Our products are widely used in various applications such as Automotive, Energy, Lighting, Medical, Home Furnishings, Machinery & Equipment etc. Below are our advantages:

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings. Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis and 5-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency. We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart. We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.