Aluminum parts can be finished using either liquid painting or powder coating.

While both processes provide a protective layer to the parts, each method has its own distinct characteristics, benefits, and drawbacks. These coatings contain pigments, additives, and resins.

The key distinction is that liquid painting involves a solvent, while powder coating utilizes dry powder. Other variations include the surface texture, color matching, and application technique.

Aluminum Liquid Painting

Aluminum liquid painting is a method of applying a coating to aluminum parts by using a spray of wet paint.

The paint can be applied in one or more layers, depending on the desired outcome and the specific type of paint used. This technique offers excellent resistance to impact, wear, corrosion, and chemical damage.

Surface Texture

Both liquid painting and powder coating offer a variety of finishes, but each is best for different types. Liquid painting is excellent for achieving a high-gloss finish, while powder coating works well for matte finishes.

Powder coating usually has a more textured and coarse finish than liquid paint, although smooth results are possible.

Coat Thickness

Powder coating provides a thicker layer than liquid painting. The thickness of a powder coat typically ranges from 2 mm to 8 mm, while liquid paint ranges from 0.5 mm to 1.5 mm.

Powder coating allows precise control over the thickness of the coat. Use a gauge to measure the thickness to decide whether it is a powder coat.

Color Matching

While color isn’t a foolproof indicator of the type of coating, it can give some insight. Liquid paints offer easier customization of colors compared to powder coatings.

Mixing liquid paints can produce new colors, while mixing dry powders may lead to a speckled pattern. Therefore, a speckled appearance suggests a powder coating.

Consistency of Application

Powder coating typically results in a more even finish compared to liquid painting. Powder coating uses charged particles for a uniform coat, even on intricate surfaces.

Liquid painting can lead to variations such as drips, ripples, or bubbles, causing uneven thickness.

Flexibility of Coating

Powder coating can accommodate surfaces that expand or contract slightly without cracking or peeling. If you find cracks or chips on some parts, the part is likely painted.

If the part faces extreme temperatures without chipping or cracking, it may be powder-coated. Parts such as springs often receive powder coatings.

Keep in mind that thermoset powder coatings applied in thick layers can crack. Manufacturers and finishing specialists avoid this by applying thin layers of powder coating.

Therefore, paint chipping or cracking is more common before thermoset powder coatings show wear.

Comparing Liquid Painting and Powder Coating: Which is Superior?

Here is a table summarizing the comparison between liquid painting and powder coating, highlighting key points:

| Feature | Liquid Painting | Powder Coating |

|---|---|---|

| Resistance | Susceptible to chipping and scratching | Provides better resistance due to thermal bonds |

| Layer Thickness | Typically thinner layers | Creates thicker layers, ideal for outdoor use |

| Adaptability | Suitable for various applications | Preferred for high-stress environments in transportation |

| Color Retention | Can be affected by sunlight, heat, moisture | Maintains color well, though can chalk over time |

| Safety | Potentially hazardous (flammable) | Safer to apply and store; no VOCs |

| Cost-Effectiveness | Lower utilization rate; overspray waste | Higher utilization rate; recyclable powder |

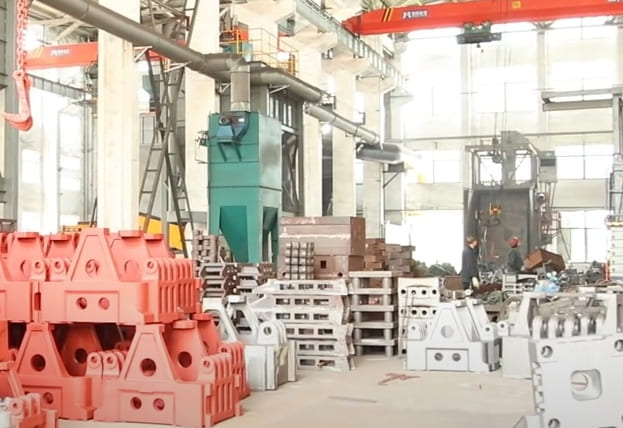

High-Quality Liquid Painting Services at Yongzhu Metal

Yongzhu Metal provides exceptional aluminum liquid painting services utilizing cutting-edge technologies in surface finishing. This process improves the aesthetic appeal and longevity of your aluminum parts.

Yongzhu Metal’s professionals maintain that painting your aluminum components can boost productivity. As with most metals, aluminum can oxidize and corrode, potentially affecting the part’s performance.

Yongzhu Metal holds ISO 13485, ISO 9001, and IATF 16949 certifications, ensuring the quality of the parts you receive.

Additionally, the company is REACH and ROHS compliant, guaranteeing that all surface finishing services adhere to current industry standards for performance, quality, and safety.

For top-notch liquid painting services, Yongzhu Metal is the place to go. Drop me an email with your ideas, and I’ll get back to you swiftly!