CNC (Computer Numerical Control) machining is the transformative technology that converts your design dreams into precise, three-dimensional parts.

Whether you’re an inventor, entrepreneur, or engineer, choosing the right CNC machine shop can make or break your project.

This guide simplifies the process by helping you identify and select the best CNC machining partner near you.

Why CNC Machining Matters

CNC machining revolutionizes manufacturing with its unparalleled precision and versatility.

It’s not just for large-scale industries; hobbyists, medical innovators, and aerospace developers alike benefit from this technology.

By programming machines to sculpt parts with exact specifications, CNC machining eliminates human error, ensures uniformity, and expands creative possibilities.

Understanding Machine Capabilities

One of the most critical aspects of selecting a CNC shop is understanding the machines available.

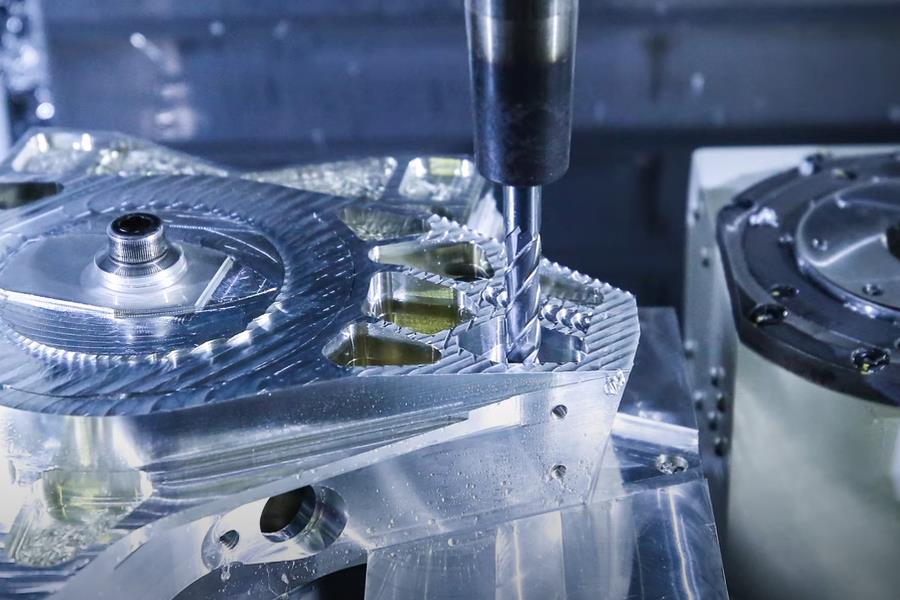

Shops equipped with 3-axis CNC machines are ideal for simpler geometries like flat surfaces or shallow cavities.

For intricate shapes and detailed contours, 5-axis CNC machines stand out. These advanced setups allow tools to rotate in multiple directions, reducing setup times and achieving unmatched complexity.

Knowing your project’s requirements helps you decide which type of shop to approach.

Material Compatibility is Key

Every CNC machine shop specializes in specific materials.

Whether it’s lightweight aluminum, durable stainless steel, or tough titanium, matching your project’s material with the shop’s expertise ensures the desired outcome.

For example, shops specializing in plastics may lack the tools necessary to handle heavy metals like titanium, which require specialized cutting strategies.

Experience Matters

An experienced CNC machine shop isn’t just about better machinery. Years of expertise bring foresight, enabling professionals to anticipate challenges and adapt quickly.

Before committing, research testimonials, case studies, and previous projects. A shop with a proven track record in your industry will likely meet—and exceed—expectations.

Cost vs. Value

Choosing based solely on price often leads to compromises in quality or delayed deadlines. Instead, evaluate value.

Reliable shops provide competitive pricing while prioritizing quality assurance, realistic lead times, and customer support. Remember, paying slightly more for quality often saves time and resources in the long run.

Searching for High-Quality for Cast Aluminum Parts?

You’ve come to the right place! Yongzhu Casting is a certified die casting manufacturer with over 20 years of expertise in the industry.

We have successfully completed numerous die casting projects for Aluminum casting parts, particularly in your industry.

Zhejiang Yongzhu Casting Technology Co., Ltd.

Location: Zhejiang, Shaoxing

Company type: Manufacturing

Year Founded: 2004

Main Products: Aluminium die casting, Mold Making, Die Casting, Sand Casting, Gravity Casting

Leading Chinese producer Yongzhu Casting is formerly known as Hangzhou Higer Metal Products Co., Ltd., was established in 2004.

With 20 years of experience in the industry, we are a specialized manufacturer in Aluminum casting and Machining.

Our products are widely used in various applications such as Automotive, Energy, Lighting, Medical, Home Furnishings, Machinery & Equipment etc. Below is one of our products.

It’s worth mentioning that the evolution of rapid logistics has transformed how industries approach purchasing. Aluminum casting orders can now be sourced from overseas suppliers efficiently.

For instance, working with YONGZHU CASTING, you can inquire, order, and even find better value than your local options—all while maintaining assured quality.

Design Review & DFM Support

Our professionals will evaluate your designs and provide suggestions for cost savings. Additionally, we offer Design for Manufacturing (DFM) assistance and conduct mold flow analyses to facilitate efficient production.

State-of-the-Art Manufacturing Equipment

Our facility is equipped with advanced hot-chamber and cold-chamber die casting machinery for aluminum and zinc production.

We also utilize high-precision CNC machines in a temperature-controlled workshop, featuring 3-Axis, 4-Axis and 5-Axis setups to manage any project you have.

Rigorous Quality Control Measures

Our dedicated quality control team ensures that all parts meet the highest standards of quality and consistency. We employ high-accuracy measurement instruments, including CMM, spectrometers, and X-ray detectors.

Comprehensive Surface Treatment Options

We provide a variety of surface finishing techniques for your precision die casting components. Our in-house services include cleaning, polishing, anodizing, shot blasting, and painting.

Flexible Project Acceptance

While larger manufacturers often shy away from low-volume projects, and smaller ones may struggle with quality, Yongzhu Casting stands apart. We prioritize customer satisfaction and willingly accept high-mix, low-volume projects like yours.

Key Services to Look For in a CNC Machine Shop:

- Prototyping: Create and test designs before full-scale production.

- Mass Production: Scalable solutions for high-volume needs.

- Repair Services: Maintenance for CNC equipment to ensure uptime.

Advanced Considerations:

- 5-Axis Machining: For complex geometries requiring precision.

- Quick Turnaround: Capabilities to handle tight deadlines.

- Specialized Materials: Expertise in unique alloys like titanium or magnesium.

Comparison of 3-Axis vs. 5-Axis CNC Machines

| Feature | 3-Axis CNC | 5-Axis CNC |

|---|---|---|

| Complexity | Simple parts, flat surfaces | Intricate designs, complex curves |

| Setup Time | Longer | Shorter |

| Ideal For | Basic components | Aerospace, medical, and automotive |

| Cost Efficiency | Lower initial cost | Higher value for complex parts |

Material Expertise Across Shops

| Material | Characteristics | Ideal Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | Prototypes, automotive components |

| Stainless Steel | Durable, excellent for precision | Medical tools, industrial machines |

| Titanium | High strength-to-weight ratio | Aerospace, biomedical implants |

| Plastics | Lightweight, versatile | Consumer goods, enclosures |

10 FAQs About Finding CNC Machine Shops

1. What is CNC machining?

CNC machining is a computer-controlled process that produces precise parts from materials like metal, plastic, or wood.

2. How do I find CNC shops near me?

Search online directories, local business listings, or use Google Maps to locate nearby shops.

3. What is the difference between 3-axis and 5-axis CNC?

3-axis machines handle simpler parts, while 5-axis machines are ideal for complex geometries.

4. What materials can CNC machines work with?

CNC machines can process metals (aluminum, steel, titanium), plastics, and even wood.

5. Are CNC services expensive?

Costs vary by project complexity, material, and quantity. Obtain multiple quotes for comparison.

6. How long does CNC machining take?

Lead times depend on part complexity and production volume, ranging from a few days to weeks.

7. Can CNC shops help with design?

Many shops offer design consultation and prototyping services.

8. What certifications should a CNC shop have?

Look for ISO certifications or industry-specific credentials, like AS9100 for aerospace.

9. Are CNC shops environmentally friendly?

Shops with sustainable practices reduce material waste and energy consumption.

10. What industries benefit from CNC machining?

Industries include aerospace, medical, automotive, consumer electronics, and more.

Conclusion

CNC machining unlocks endless possibilities for innovators across industries.

By carefully selecting a CNC shop with the right machinery, material expertise, and customer service, you can bring your ideas to life efficiently and precisely.

Take the time to compare services, read reviews, and ensure the shop aligns with your project’s goals. Whether it’s prototyping, mass production, or specialized repairs, the right CNC partner is your gateway to success.