What is Hot Cracking in Die Casting?

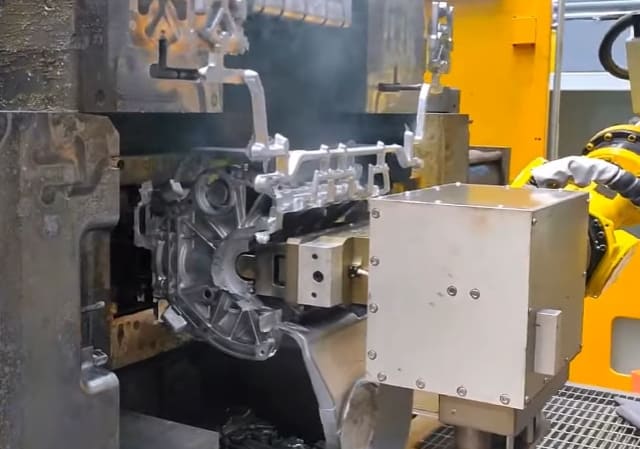

Hot cracking refers to defective tears that occur during the final stages of die-casting solidification.

Characterized by irregular, crooked cracks, this defect is prevalent in malleable iron and steel castings, as well as some light alloy castings.

Hot cracking significantly affects the integrity and usability of the cast parts, necessitating a thorough understanding of its causes and prevention methods.

Characteristics of Hot Cracking

Hot cracks can vary in length, color, shape, and depth, but they typically exhibit the following features:

- Oxidized color without metallic luster.

- Irregular, uneven, tortuous shape.

- Wide opening that narrows internally.

- Initiation and propagation along the grain boundary.

- Fractures running through the entire casting.

- Dendrites affecting the cross-section.

- Interior cracks that don’t extend to the surface.

These characteristics help differentiate hot cracks from cold ones. For example, torn surfaces often appear black in steel or iron castings, while aluminum die castings exhibit greyish tears.

Types of Hot Cracks

Hot cracks in die casting can be categorized based on their location:

- Outer Cracks: Visible on the casting surface, typically at corners, edges, or sections with sharp thickness changes.

- Inner Cracks: Form within the casting and require sophisticated inspection methods for detection, often occurring at the final stages of solidification.

Causes of Hot Cracking

Several factors contribute to the formation of hot cracks, including:

- Internal Tension: Prolonged solidification time increases internal tension, leading to cracks.

- Sharp Corners: Sharp edges that solidify last remain hotter and are more prone to cracking.

- Shrinkage Porosity: Hot spots that fail to solidify evenly near surfaces develop shrinkage porosity, causing surface fractures.

- Thermal Control: Poor thermal control can lead to excessive contraction and cracking.

- Die Movements: Negligible shifts in the die during separation can trigger cracks due to faulty dragging forces.

- Uneven Ejection: Drags or sticking issues during ejection can twist the casting, causing surface cracks.

- Flowing Patterns: Thin oxide layers formed during casting can hinder solidification, leading to fractures.

- Incorrect Proportion: Improper alloy proportions and excessive modifiers can cause uneven solidification and hot tears.

- Excessive Variation: Excessive distortion in the die casting process can lead to hot cracks.

Spots Prone to Hot Cracking

Certain areas of a casting are more susceptible to hot cracks due to concentrated shrinkage stress:

- Uneven wall thicknesses

- Small interior angles

- Large linear shrinkage areas

- Lap joint bifurcations

- Larger or smaller risers

Effects of Hot Cracking in Casting

Hot cracks negatively impact the quality and usability of cast parts in several ways:

- Poor Aesthetics: Surface imperfections reduce the aesthetic value of the casting.

- Compromised Strength: Structural integrity is compromised, making the casting prone to failure under stress.

- Improper Sealing: Cracks in thinner walls lead to leakage, making the casting unsuitable for hydraulic or automotive applications.

- Increased Waste: Fractured castings result in higher production costs and increased metal waste.

Preventing Hot Tears

To minimize hot cracking, several mechanical and metallurgical countermeasures can be implemented:

| Aspect | Key Points | Actions |

|---|---|---|

| Improved Casting Mold | Uniform wall thickness and avoiding sharp corners reduce stress concentration. | Design molds with consistent wall thickness and rounded corners. |

| Superior Alloy Melting | Processes like degassing or refining remove oxides and gases. | Implement degassing or refining during alloy melting. |

| Correct Casting Process | Proper cooling and solidification methods prevent fractures. | Use minimal dwelling time and effective thermal control. |

| Proper Alloy Constituents | Correct range of alloy constituents (Fe, Cu, Si) reduces hot tears. | Ensure alloy constituents are within the correct range. |

| Slowing Down the Process | Monitoring and slowing down the process helps detect irregularities. | Monitor the casting process and slow down as needed. |

| Instant Fixing Actions | Applying pressure or heating can reverse potential cracks. | Apply pressure on hot spots or heat cold spots. |

Conclusion

While it is challenging to eliminate hot cracking entirely, adopting preventive measures can significantly reduce the occurrence of this defect.

The effectiveness of these measures depends on the choice of alloy and the quality of the mold used. Implementing these strategies ensures higher quality and more reliable cast parts, enhancing their overall performance and usability.

Contact us today to discuss your project needs and receive a quote, you can trust us to deliver exceptional castings that meet your requirements.