What is Cast Aluminum?

Cast aluminum is an alloy made from aluminum that is melted and poured into molds to create specific shapes and parts.

Known for its lightweight and excellent corrosion resistance, cast aluminum is widely used in various applications.

Definition and Composition

Cast aluminum primarily consists of aluminum with a small percentage of other metals, such as silicon and copper, to enhance its properties.

This combination allows for improved casting characteristics and mechanical strength.

What is Cast Iron?

Cast iron, on the other hand, is an alloy of iron, carbon, and silicon. It’s known for its excellent casting properties and is often used in heavy-duty applications, such as engine blocks and cookware.

Its strength and durability make it suitable for sectors requiring robust materials.

Advantages of Cast Aluminum

One of the standout features of cast aluminum is its lightweight quality.

This property can reduce the overall weight of products, which is a significant advantage in automotive design.

Furthermore, cast aluminum exhibits remarkable strength-to-weight ratios, making it suitable for various applications.

Cast Aluminum Strength

Many ask, “How strong is cast aluminum?”

The answer lies in its tensile strength, which can vary depending on the alloy used. Generally, it provides comparable strength to cast iron while being significantly lighter.

Disadvantages of Cast Aluminum

Despite its many advantages, cast aluminum has its drawbacks. The cost can be higher than cast iron, making it less desirable for large-scale applications.

Additionally, while cast aluminum is strong, it can be brittle, raising concerns about its durability in extreme conditions.

Is Cast Aluminum Heavy?

A common misconception is that cast aluminum is heavy; in reality, it is much lighter than cast iron.

This difference makes it easier to handle and transport, a vital aspect in industries like automotive manufacturing.

Advantages of Cast Iron

Cast iron shines in its durability and wear resistance. Its ability to withstand high temperatures and corrosive environments makes it ideal for heavy machinery and construction equipment.

Cast Iron Applications

In sectors such as construction and automotive, cast iron is indispensable. From engine blocks to cookware, it proves its versatility and reliability.

Disadvantages of Cast Iron

Cast iron is not without its flaws. Its weight can be a disadvantage, especially when lighter materials like aluminum are preferable. Additionally, cast iron is prone to rust if not properly maintained, which can limit its application in certain environments.

Comparing Prices

When considering cast iron vs aluminum, price often comes into play. Cast iron typically costs less upfront, but the long-term maintenance and performance should also be factored in.

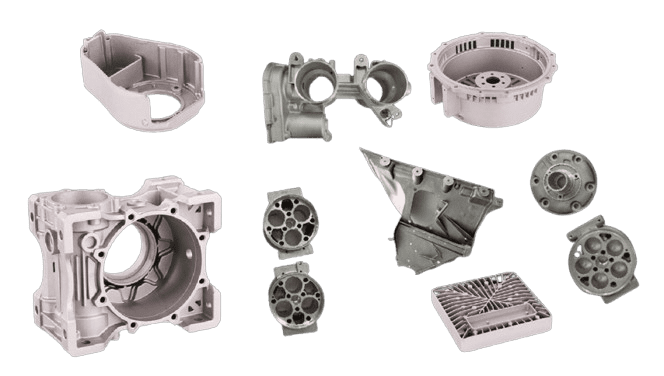

Common Applications of Cast Aluminum

Cast aluminum is commonly found in automotive parts, cookware, and structural components. Its versatility and durability make it a preferred choice in many industries.

The Manufacturing Process of Cast Aluminum

How Cast Aluminum is Made

The manufacturing process begins with melting aluminum in a furnace. Once molten, it is poured into molds, where it cools and solidifies into the desired shape.

Types of Casting Processes

Several casting methods are used for aluminum, including sand casting, die casting, and investment casting.

Each method offers different benefits, depending on the intended application and production scale.

Comparing Cast Aluminum and Cast Iron

Strength and Durability

When comparing cast aluminum to cast iron, aluminum generally exhibits better strength-to-weight ratios.

While cast iron is typically stronger in terms of compression, cast aluminum offers better tensile strength, making it suitable for a wider range of applications.

Weight Differences

Cast aluminum is significantly lighter than cast iron, making it easier to handle and transport. This weight advantage is crucial in industries where reducing mass is essential, such as automotive and aerospace.

Strength Characteristics of Cast Aluminum

How Strong is Cast Aluminum?

Cast aluminum is strong enough for many applications, especially where weight savings are crucial. Its strength can vary depending on the specific alloy used, but it is generally considered durable.

Comparison with Wrought Aluminum

While cast aluminum is strong, wrought aluminum typically has superior strength due to its processing method, which aligns the grain structure.

Cast aluminum is better for complex shapes, while wrought aluminum is preferred for high-stress applications.

Properties of Cast Aluminum

Corrosion Resistance

One of the standout properties of cast aluminum is its excellent corrosion resistance. The natural oxide layer that forms on aluminum protects it from the elements, making it ideal for outdoor applications.

Thermal Conductivity

Cast aluminum also boasts good thermal conductivity, allowing it to efficiently dissipate heat. This property is beneficial in applications such as cookware and heat exchangers.

Is Cast Aluminum Heavy?

Density Compared to Other Metals

Cast aluminum is relatively lightweight compared to metals like cast iron or steel. This lower density allows for easier handling and reduced shipping costs.

Applications Benefiting from Lightweight

The lightweight nature of cast aluminum makes it ideal for automotive parts, aircraft components, and other applications where reducing weight is crucial for performance.

Is Cast Aluminum Brittle?

Understanding Brittle vs. Ductile

While cast aluminum is generally not considered brittle, it can be less ductile than wrought aluminum.

Ductility refers to a material’s ability to deform under stress, and cast aluminum may not withstand extreme impacts as well as some other metals.

Factors Influencing Brittleness

Factors such as alloy composition and casting quality can influence the brittleness of cast aluminum. Properly formulated and processed aluminum can exhibit good toughness and resilience.

Common Myths About Cast Aluminum

Cast Aluminum vs. Aluminum

A common misconception is that cast aluminum is a lower-quality form of aluminum.

In reality, cast aluminum has specific advantages that make it suitable for particular applications, including better shape retention and dimensional accuracy.

Misconceptions About Strength

Another myth is that cast aluminum is inherently weak. While it may not match the strength of some steel alloys, it is strong enough for many demanding applications, especially when weight is a concern.

Summary of Cast Aluminum vs. Other Materials

Cast Aluminum vs. Cast Iron

While cast iron is stronger in compression, cast aluminum’s lightweight and resistance to corrosion make it a favorable choice for many applications.

Aluminum vs. Cast Aluminum

Aluminum itself refers to the pure metal, while cast aluminum is a specific form designed for casting processes. Each has its unique benefits and is chosen based on the application’s requirements.

Conclusion: The Versatility of Cast Aluminum

Cast aluminum is a versatile material that offers an excellent balance of strength, weight, and corrosion resistance.

Understanding its properties and how it compares to other materials, like cast iron, can help in making informed decisions for various applications.

Whether in automotive parts, cookware, or structural components, cast aluminum continues to prove its value across many industries.