In the realm of metal finishing, understanding the nuanced differences between chromate and chrome coatings is essential for selecting the right type of protection and aesthetics for your products. This guide delves deep into both processes, offering insights into their applications, benefits, and key distinctions.

Chromate Coating: Enhancing Corrosion Resistance

What is Chromate Coating?

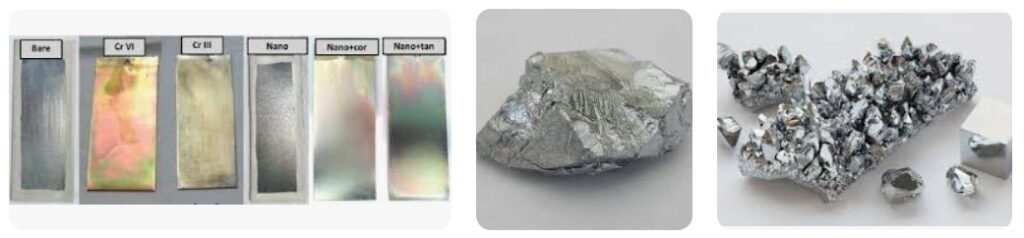

Chromate coating, also known as chromate conversion coating, is a type of surface treatment for metals such as aluminum, zinc, and their alloys. This process involves the application of a chromate solution that reacts with the metal surface to form a protective layer. This layer significantly enhances the metal’s corrosion resistance, making it an ideal choice for a wide range of industrial applications.

Applications of Chromate Coating

- Corrosion Protection: Primarily used to increase the durability of metal parts exposed to harsh environments.

- Primer: Acts as an effective primer to improve adhesion of paints and other coatings.

- Decorative Finishes: Provides a range of colors, including clear, green, and black, for aesthetic purposes.

Benefits of Chromate Coating

- Enhanced Durability: Significantly increases the lifespan of metal components.

- Environmental Resistance: Offers superior protection against humidity, salt spray, and other corrosive elements.

- Cost-Effective: Compared to other coatings, chromate is relatively inexpensive and efficient to apply.

Chrome Coating: Achieving Superior Aesthetics and Durability

What is Chrome Coating?

Chrome coating, or chromium plating, involves electroplating a thin layer of chromium onto a metal or plastic object. This process not only provides a mirror-like, aesthetic finish but also offers excellent wear resistance. Chrome coating is distinguished by its two main types: decorative chrome and hard chrome.

Applications of Chrome Coating

- Decorative Chrome: Used for automotive trim, bathroom fixtures, and appliances for its glossy finish.

- Hard Chrome: Applied to industrial equipment, hydraulic rods, and tools for its durability and resistance to wear.

Benefits of Chrome Coating

- Aesthetic Appeal: Offers a high-gloss finish that enhances the visual appeal of any product.

- Wear Resistance: Provides a hard surface that resists scratching and wear.

- Corrosion Resistance: Although primarily used for its appearance, it also offers a degree of corrosion resistance.

Comparing Chromate and Chrome Coatings

While both coatings serve to protect and enhance the appearance of metal objects, their applications and benefits vary significantly.

- Application Process: Chromate coating is a chemical conversion process, while chrome coating requires electroplating.

- Environmental Impact: Chromate coatings are subject to environmental regulations due to their use of hexavalent chromium. Chrome plating also faces regulatory scrutiny but is primarily challenged by its waste management.

- Performance: Chrome coatings generally provide superior wear resistance, whereas chromate coatings are sought after for their corrosion resistance.

Choosing the Right Coating

Selecting between chromate and chrome coatings depends on the specific requirements of the application, including desired aesthetics, environmental exposure, and budget constraints. It’s crucial to weigh the benefits of each coating type against these factors to make an informed decision.

In conclusion, understanding the distinct characteristics, applications, and benefits of chromate and chrome coatings is pivotal for ensuring optimal performance and durability of metal components.

Drop me an email with your ideas, and I’ll get back to you swiftly!