Introduction

Warpage is a common issue in plastic injection molding, characterized by undesired deformations or distortions in molded parts. These distortions can compromise dimensional accuracy, functionality, and aesthetics of the final product.

Understanding the causes, preventive measures, and remediation techniques for warpage is crucial for ensuring high-quality injection-molded components. This comprehensive guide explores the phenomenon of warpage in plastic injection molding and offers insights into effective mitigation strategies.

Causes of Warpage

Warpage in injection-molded parts can occur due to various factors, including:

- Uneven Cooling: Inadequate or uneven cooling of the molded part can lead to differential shrinkage rates, resulting in warpage.

- Residual Stress: Internal stresses induced during the molding process, such as molecular orientation or thermal gradients, can cause warpage as the part relaxes.

- Material Properties: Certain materials are more prone to warpage due to their inherent shrinkage rates, thermal conductivity, or crystallization behavior.

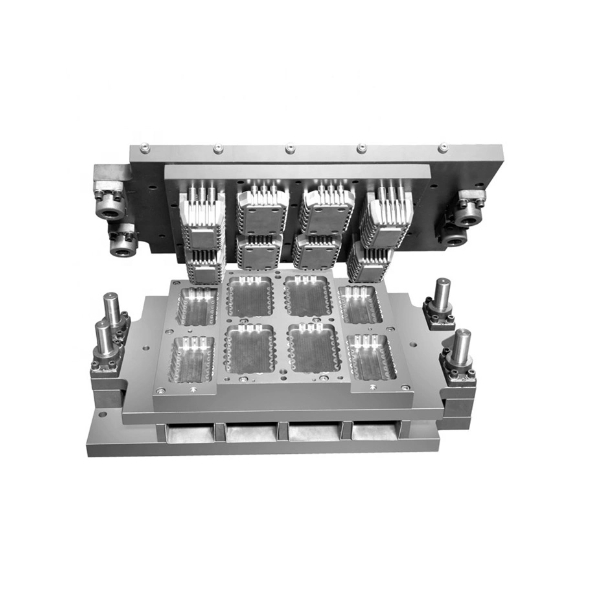

- Tooling Design: Poor mold design, including inadequate cooling channels, improper gating, or insufficient draft angles, can exacerbate warpage issues.

- Processing Conditions: Incorrect injection parameters, such as melt temperature, injection speed, or pack pressure, can contribute to warpage by affecting material flow and distribution.

Prevention Methods

To prevent warpage and ensure dimensional stability in injection-molded parts, consider the following preventive measures:

- Optimized Cooling System: Design the mold with uniform cooling channels and optimize cooling time to minimize differential cooling and reduce warpage.

- Material Selection: Choose materials with lower shrinkage rates, good flow properties, and balanced mechanical properties to mitigate warpage tendencies.

- Proper Gate Design: Optimize gate placement and size to ensure uniform material flow and reduce internal stresses that can lead to warpage.

- Optimized Processing Parameters: Fine-tune injection parameters to achieve optimal filling, packing, and cooling conditions that minimize residual stresses and warpage.

- Mold Design Optimization: Incorporate draft angles, fillets, and adequate venting in the mold design to facilitate part ejection and minimize warpage.

Remediation Techniques

In cases where warpage has already occurred, the following techniques can help remediate the defects:

- Heat Treatment: Subjecting the warped parts to controlled heating or annealing processes can relieve internal stresses and restore dimensional stability.

- Secondary Operations: Machining, sanding, or trimming can be employed to correct localized warpage and achieve the desired part geometry.

- Re-molding: In extreme cases, re-molding the parts using optimized processing parameters and mold modifications may be necessary to eliminate warpage issues.

Conclusion

Warpage in plastic injection molding poses challenges for manufacturers, affecting part quality, functionality, and production efficiency.

By understanding the causes of warpage and implementing preventive measures and remediation techniques, manufacturers can minimize defects, improve part quality, and enhance overall productivity in injection molding processes.

Drop me an email with your ideas, and I’ll get back to you swiftly!