The aluminum die casting machine is one of the most critical pieces of equipment in the metal casting industry. Buyers often search for machine types, price ranges, and even top brands before making procurement decisions. But while some companies invest millions in equipment, others choose to partner with manufacturers like us to get finished parts directly.

In this guide, we’ll explain what aluminum die casting machines are, how they work, their prices, the top 10 brands, and most importantly—what buyers should consider before deciding whether to buy or outsource.

What Is an Aluminum Die Casting Machine?

An aluminum die casting machine injects molten aluminum into a steel mold (die) under high pressure. Once the metal solidifies, the die opens and the part is ejected.

This process is a key branch of aluminum casting, and it delivers excellent dimensional accuracy, smooth surfaces, and high-volume repeatability. Compared with gravity die casting or investment casting, die casting is faster and better suited for mass production.

The die casting process is also divided into several categories:

- High pressure die casting (HPDC) – most common for aluminum automotive parts.

- Low pressure die casting (LPDC) – suitable for wheels and thicker parts.

- Gravity die casting – used for medium-volume parts.

👉 This makes die casting one of the most versatile aluminum manufacturing methods today.

Types of Aluminum Die Casting Machines

There are two main machine types, plus variations by tonnage:

| Process Type | Chamber Architecture | Aluminum? | Typical Applications | Why Choose It |

|---|---|---|---|---|

| High Pressure Die Casting (HPDC) | Cold-chamber | Yes | Thin-wall housings, brackets, structural parts | Fast cycles, fine features; needs vacuum/overflow control for porosity |

| Low Pressure Die Casting (LPDC) | Crucible + riser tube (no plunger) | Yes | Wheels, thicker sections, pressure-tight parts | Smooth, low-turbulence fill → better integrity/weldability; slower than HPDC |

| Gravity Die Casting (GDC) | Tilt/static gravity into permanent mold | Yes | Medium-volume, thick-wall components, pump bodies | Lower equipment cost, good mechanicals; slowest cycle |

| HPDC – Hot-chamber | Integrated gooseneck | No(for Al) | — | Not used for Al due to high melting point & iron dissolution of the gooseneck |

Aluminum Die Casting Machine Price Guide

One of the most common questions buyers ask is: How much does an aluminum die casting machine cost? The answer depends heavily on the machine’s clamping force (tonnage), as this determines the size of parts it can produce.

Below is a practical reference range covering the full spectrum of aluminum cold-chamber die casting machines—from 180T laboratory-size units to massive 2000T automotive structural machines.

| Tonnage (Clamping Force) | Typical Applications | Price Range (USD) | Notes |

|---|---|---|---|

| 180–300T | Small aluminum parts, LED housings, electronics, 3C enclosures | $60,000 – $120,000 | Ideal for high-volume small parts. Compact footprint, lower cycle time. |

| 400–600T | Medium automotive housings, small engine covers, motorcycle components | $120,000 – $220,000 | Flexible for mid-size castings; often chosen by Tier-2 auto suppliers. |

| 800–1000T | Transmission cases, gearbox housings, structural aluminum components | $200,000 – $400,000 | Workhorse range for automotive and industrial parts. |

| 1200–1600T | EV battery housings, large engine blocks, industrial pump housings | $400,000 – $700,000 | Preferred for structural automotive parts; supports vacuum systems. |

| 1800–2000T+ | Large chassis parts, cross-members, aerospace aluminum housings | $700,000 – $1,200,000+ | Rare, heavy-duty machines. Required for mega-castings and very large parts. |

Key Insights

- Bigger isn’t always better:

Don’t select tonnage by weight alone. A small but flat housing may need higher tonnage because of its projected area. - Investment scales sharply:

Jumping from 300T to 800T may double the price, but jumping from 1200T to 2000T can nearly triple it. - Used machines:

A second-hand 800T unit may sell for $100k–$150k, compared to $250k–$350k for new—but risks include outdated controls, worn tie-bars, and higher downtime. - Location matters:

Machines built in Asia (e.g., die casting machine price in India or China) are usually 15–25% cheaper than European or Japanese brands, but long-term performance and service support must be factored in.

Key Factors to Consider Before Buying an Aluminum Die Casting Machine

When evaluating an aluminum die casting machine, buyers often hear technical terms like clamping force or casting area. Here’s what they actually mean in practice, and why they matter for your production.

| Factor | What It Means | Why It Matters | Buyer’s Takeaway |

|---|---|---|---|

| Clamping Force (Tonnage) | The pressure that keeps the mold closed during injection. | If tonnage is too low, molten aluminum leaks (flashing), causing scrap. | Small parts → 300T; medium parts → 800T; large structural parts → 1600T+. Bigger parts need higher tonnage. |

| Casting Area | The surface of the mold facing the molten metal. | Larger projection areas need stronger clamping force—even if weight is the same. | Don’t judge only by weight. A flat 2 kg housing may need more tonnage than a solid 2 kg block. |

| Machine Brand | Reputation and engineering quality of the machine maker. | Affects precision, uptime, and ease of finding spare parts. | Top brands (Bühler, Toshiba) = higher cost but fewer defects. Local brands = cheaper but may need more maintenance. |

| Automation & Options | Extra features like robotic extraction, vacuum casting, sensors. | Boosts consistency, lowers labor cost, but increases upfront price. | High-volume production → automation pays off. Small runs → basic models are enough. |

| After-Sales Support | Service network and availability of spare parts. | Poor support = weeks of downtime when parts fail. | Always check if local dealers can supply spares quickly. Service coverage often matters more than purchase price. |

Top 10 Aluminum Die Casting Machine Brands in 2025

If you’re curious about the top global suppliers, here are the most recognized names:

- Bühler (Switzerland) – Cold chamber HPDC, strong automation, used widely in automotive.

- Toshiba (Japan) – Known for durability, used in electronics and auto parts.

- Frech (Germany) – Leader in hot chamber machines for zinc and magnesium.

- Idra (Italy) – Specializes in very large machines (2000T+), popular in EV battery housings.

- LK Machinery (China) – Asia’s largest supplier, full product line, strong cost competitiveness.

- Yizumi (China) – Rapidly growing, reliable mid-range option with good service.

- Kurtz Ersa (Germany) – Strong in gravity and low pressure casting machines.

- UBE (Japan) – Known for ultra-large cold chamber machines.

- Albertini (Italy) – Historical brand, mid to high-end positioning.

- Sodic (Japan) – Precision hot chamber machines, excellent for magnesium parts.

👉 Knowing the top 10 helps buyers benchmark machine capabilities, but remember: owning machines is not always necessary—outsourcing is often smarter.

Applications of Aluminum Die Casting Machines

- Small machines (<300T) → lighting housings, consumer electronics.

- Medium machines (~800T) → automotive gear housings, motorcycle covers.

- Large machines (1600T+) → EV battery trays, structural components.

This shows why aluminum die casting alloys are so widely used: lightweight, high strength, and excellent corrosion resistance.

Advantages and Disadvantages of Die Casting

| Advantages | Disadvantages |

|---|---|

| High dimensional accuracy | High mold/tooling cost |

| Smooth surface finish | Only suitable for large production runs |

| Excellent repeatability | Limited for very large/thick parts |

| High production efficiency | Maintenance costs can be high |

👉 This balance is why many buyers prefer to work with aluminum die casting companies rather than buying their own machine.

Advanced FAQ — Aluminum Die Casting Machines (HPDC, Cold-Chamber Focus)

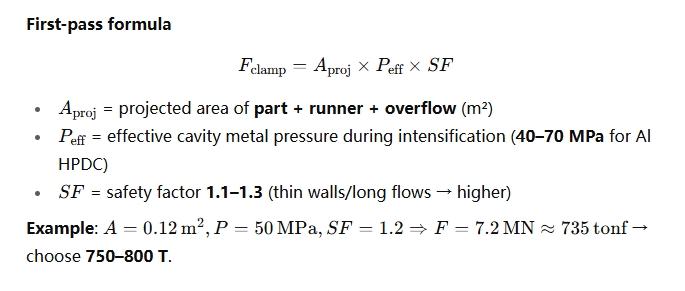

1) How do I size the clamping force for an aluminum part?

2) What minimum wall thickness and flow length can I expect?

- Typical production Al HPDC wall: 1.5–2.5 mm (best-case ~1.0–1.2 mm with highly optimized tooling + vacuum).

- Flow length / thickness (L/t): keep ≤ 80–100 for robust fill; beyond that, plan for elevated gate velocity, vacuum, and aggressive thermal control.

3) What gate velocity and fill time targets work for aluminum?

- Gate velocity: 30–60 m/s (thin walls/high surface-finishes → upper range).

- Cavity fill time: 30–120 ms depending on thickness and flow length.

- Start with gate thickness ≈ 0.8–1.2× wall and adjust by simulation/tryout.

4) What vacuum level improves weldability & porosity for Al HPDC?

- Cavity vacuum before metal arrival: ≤ 50–80 mbar (ambitious programs aim ≤ 30 mbar).

- Ensure low leak rate and adequate pump capacity vs cavity volume; position overflows at weld lines/flow ends.

- With good vacuum, porosity and entrained oxides drop, enabling welding and (in some cases) heat treatment.

5) How much intensification pressure and biscuit thickness do I need?

- Intensification: specify 50–80 MPa at the biscuit for Al; thin/long flows → higher end.

- Biscuit thickness: typically 8–15 mm (enough metal to transmit pressure without freezing too early).

6) Which aluminum alloys for which goals?

| Alloy (common codes) | Strength/ductility | Castability | Corrosion | Weldability | Heat-treat?* |

|---|---|---|---|---|---|

| A380 / ADC12 (Al-Si-Cu) | Good strength, moderate ductility | Excellent | Good | Poor–Fair (Cu) | T5 (stabilize) — T6 not recommended |

| A360 / AlSi10Mg | Moderate strength, better ductility | Very good | Very good | Fair–Good (low Cu) | T5 common, T6 possible with high-integrity HPDC |

| AlSi10Mn(Mg) (structural HPDC) | High ductility | Good | Good | Good (low Cu) | T6/T7 feasible with vacuum & low porosity |

* Heat treatment on HPDC is alloy- and porosity-dependent; see Q7.

7) Can aluminum HPDC be heat treated (T5/T6) without blistering?

- Typical A380/ADC12: use T5 artificial aging to stabilize properties; T6 risks blistering due to gas/oxides.

- Structural HPDC (e.g., AlSi10Mn(Mg)) with vacuum ≤ 50 mbar, robust overflow/venting, and low porosity can handle T6/T7; use controlled ramp rates to avoid blister.

- Always coupon-test your actual process before committing.

8) How to improve weldability of HPDC aluminum parts?

- Choose low-Cu alloys (AlSi10Mg/Mn) and run vacuum.

- Keep die lube and oxide films under control (balanced spray, clean runner/overflow).

- Specify post-cast cleaning at weld sites; confirm by bend/weld coupons.

9) What porosity levels are acceptable for pressure-tight parts?

- X-ray/CT acceptance varies by spec, but a practical target in critical zones is very low gas porosity with no connected pores to the surface.

- Leak tests: many housings target 2–6 bar hold with ≤ 2–10 sccm leakage (define your test volume/limits).

- Achieve by vacuum, balanced runners, correct fill speed, and sound overflow design.

10) How should I manage die temperature for aluminum?

- Preheat dies to 180–220 °C; run 180–250 °C with ±10 °C balance cavity-to-core.

- Local hot spots → soldering/erosion; cold zones → misruns/cold shuts.

- Use baffles/bubblers and pulsed water circuits; avoid over-spray that chills steel unevenly.

11) What shot-sleeve practices reduce air entrapment for Al?

- Sleeve fill ratio: 45–70% (too high → splash; too low → air).

- Slow shot: 0.1–0.5 m/s until the biscuit is ready to accelerate.

- Fast shot: set to hit gate velocity (see Q3) within the machine’s hydraulic stability window (plunger ~2–5 m/s typical).

- Maintain sleeve temp ~180–220 °C; correct plunger lube dosing.

12) How long will an Al HPDC die last?

- Typical range ~80k–250k shots depending on part geometry, steel grade, coatings (e.g., nitriding/PVD), thermal control, and lube discipline.

- Watch for heat-checking and soldering near gates/cores; refurb before cracks propagate.

13) What cycle times are realistic for Al HPDC?

- 15–55 s/shot depending on mass and section thickness.

- Largest chunks are solidification dwell (10–40 s) and spray/cooling (3–8 s).

- Gains come from thermal balance, optimized spray recipes, and consistent robot timing.

14) How much energy per kg should I plan?

- Casting cell only (no melting): ~0.8–1.2 kWh/kg cast metal.

- If you include melting/holding furnaces, total often ~1.5–2.2 kWh/kg (depends on furnace type, recuperation, and utilization).

15) How does chemistry control reduce soldering & defects?

- For Al-Si-Cu alloys: keep Fe ~0.9–1.3% to curb die soldering; balance Mn/Fe ≥ 0.5 to convert harmful β-Fe platelets to less-detrimental α-Fe morphologies.

- Control hydrogen via rotary degassing/flux (while air entrapment is dominant in HPDC, excess H still aggravates porosity/ blisters).

- Avoid chip/return contamination that drifts chemistry outside spec.

16) Pre-buy machine selection checklist for Al HPDC (280–2000T)

- Tonnage from projected area & pressure (Q1), not part weight.

- Shot end: plunger sizes that hit required gate velocity without unstable hydraulics.

- Vacuum system capacity vs die volume + reliable valve timing.

- Thermal control: circuits, flow, and monitoring for the die size.

- Automation: extraction, spray, trim to meet your cycle and OEE targets.

- Service: local parts & support for pumps, valves, controllers, and HMIs.

Why Partner With Us Instead of Buying a Machine?

While top brands offer impressive machines, investing in one is a multi-million-dollar decision. For most buyers, it’s far more efficient to work with an aluminum die casting manufacturer like us:

- We operate multiple machines ranging from 180T to 2000T.

- We run advanced quality checks: CMM, spectrometer, X-ray.

- We deliver finished parts without clients needing to purchase machines.

👉 Instead of spending $500,000+ on equipment, simply send us your drawing, and we’ll handle production.

📩 Contact us today for a quick quotation.